Gasoline Engine Composite Spherical Combustion Chamber Cylinder Head and Its Gasoline Engine

A combustion chamber and gasoline engine technology, applied to combustion engines, cylinders, cylinder heads, etc., can solve the problems that the advantages of spherical combustion chambers cannot be fully utilized, cannot be applied to combustion chambers of different structures, and affect the arrangement of intake and exhaust valve components. , to achieve the effect of facilitating tissue air intake, improving cooling effect, eliminating dead angles and sudden changes in shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

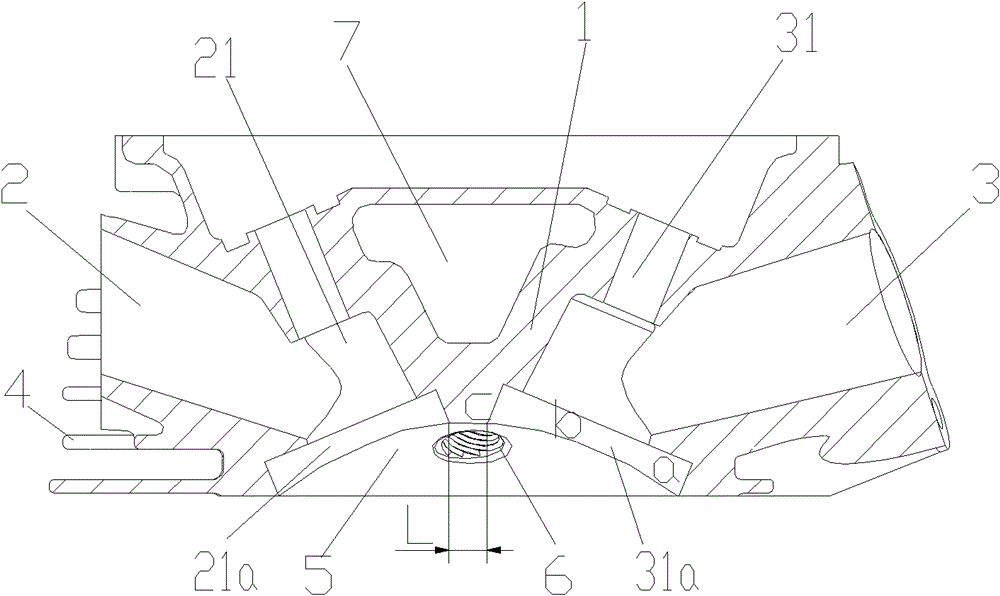

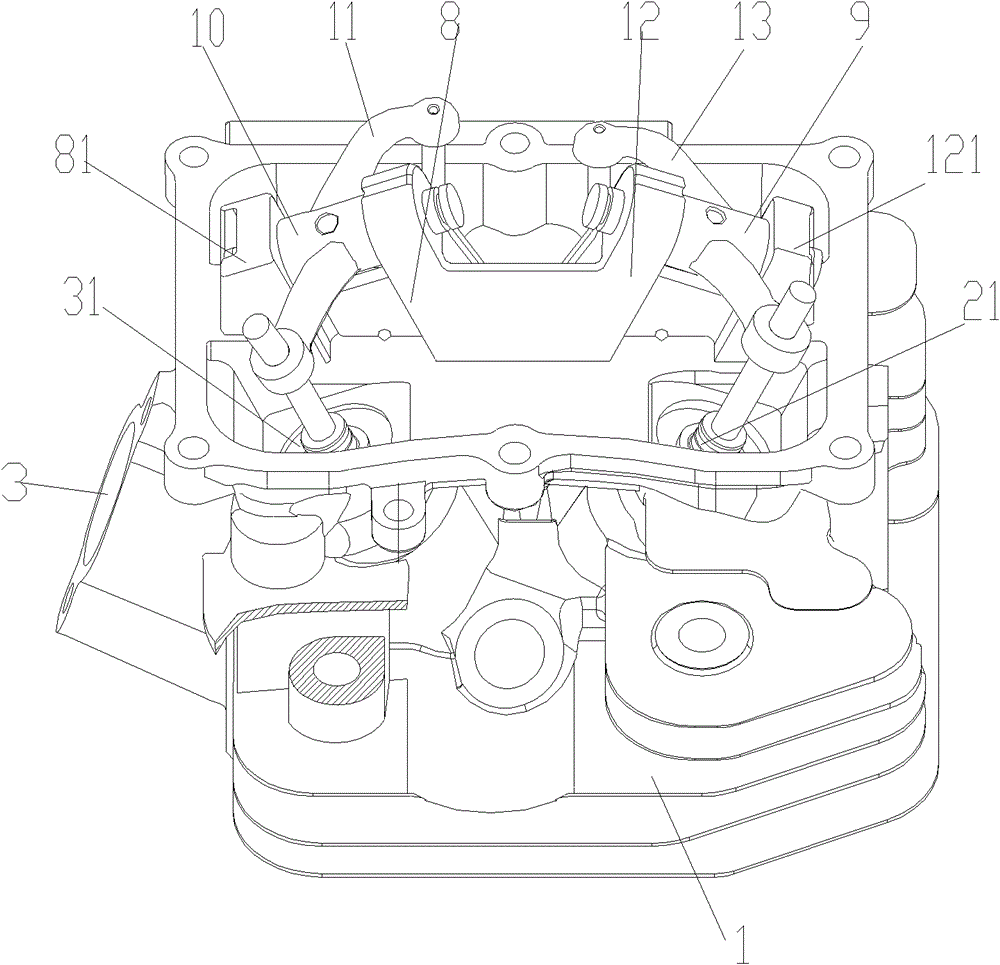

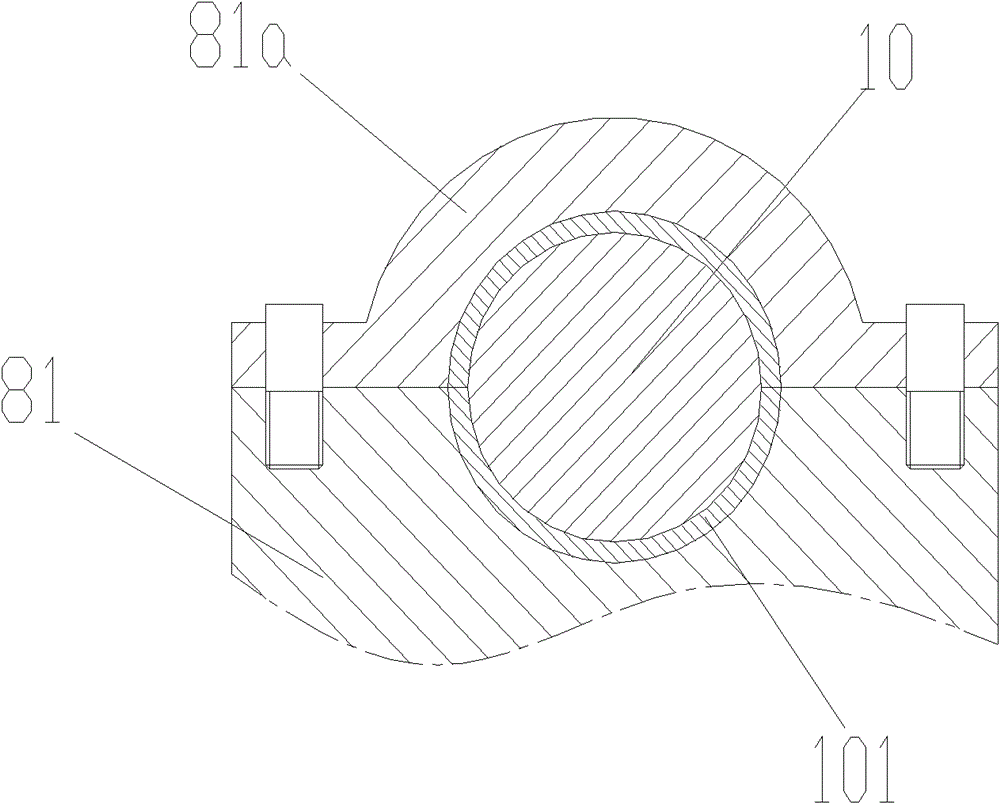

[0022] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the cylinder head rocker arm assembly of the present invention, image 3 It is a sectional view of the cooperation between the rocker shaft and the rocker seat, as shown in the figure: the cylinder head of the gasoline engine compound spherical combustion chamber in this embodiment includes the cylinder head body 1 and the intake passage 3 and the exhaust passage arranged on the cylinder head body 2 and the spark plug mounting hole 6, the outer surface of the cylinder head body 1 is provided with cooling fins 4, the inner side of the cylinder head body 1 forms the combustion chamber surface 5, and the combustion chamber surface is a composite spherical structure, which is spherical surface Ia, smooth and smooth from the bottom to the top. A curved surface b and a spherical surface IIc, the radius of the spherical surface II is greater than the radiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com