Method for preparing diamond

A diamond and equipment technology, applied in the field of diamond preparation with atomic layer deposition equipment, can solve problems such as low dependence and high impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] The present embodiment provides a kind of preparation method of diamond, specifically comprises the following steps:

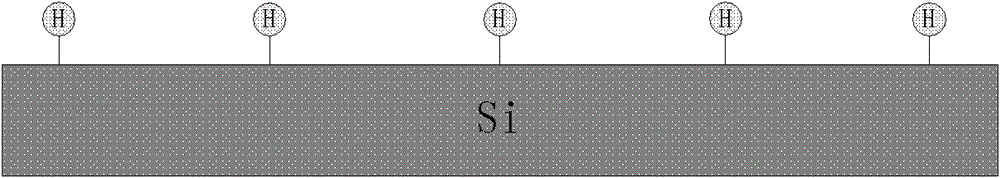

[0029] Step 101, treating the surface of the silicon (111) substrate with a standard solution and hydrofluoric acid to form a silicon-hydrogen bond on the surface of the silicon substrate, such as figure 1 As shown, wherein, the standard solution refers to: No. 1 liquid, concentrated sulfuric acid: hydrogen peroxide = 4: 1; No. 2 liquid, ammonia water: pure water: hydrogen peroxide = 1: 5: 1; No. 3 liquid, hydrochloric acid: hydrogen peroxide: pure water =1:1:6;

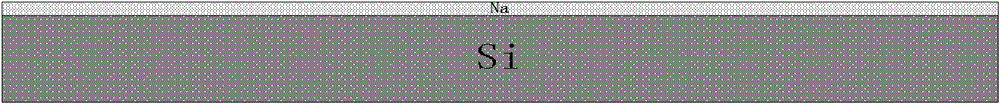

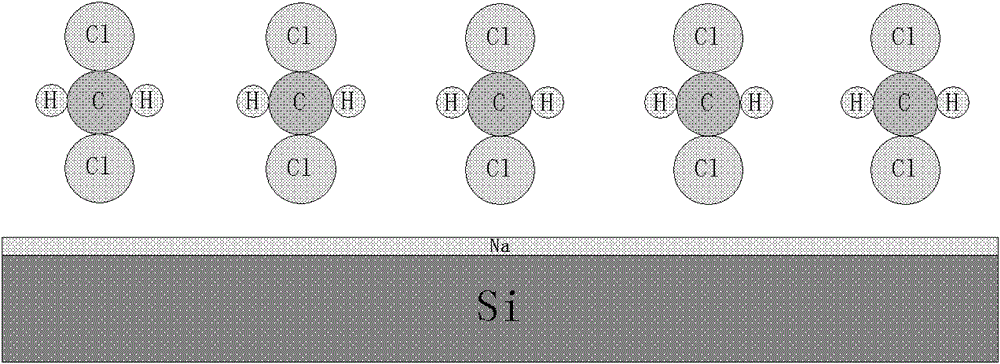

[0030] Step 102, evaporating or sputtering a layer of metallic sodium on the surface of the silicon substrate, such as figure 2 As shown, and place the silicon substrate in the reaction chamber of the atomic layer deposition equipment;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com