Composite diesel oil for automobile

A diesel and vehicle technology, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of no major breakthrough in compound diesel, hinder the development of compound diesel, poor power performance, etc., and achieve the improvement of condensation point and sulfur reduction. content, the effect of eliminating combustion soot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The composite diesel for vehicles of the present embodiment consists of the following components in parts by weight: ferrocene: 0.07 parts, diesel oil: 20 parts, dimethyl carbonate: 3 parts, tert-butanol: 1 part, isobutanol : 1.5 parts, kerosene: 15 parts, coal clean oil: 30 parts, 40 parts of heavy aromatics.

[0011] Preparation method: Physically mix 0.07 parts of ferrocene, 20 parts of diesel oil, 3 parts of dimethyl carbonate, 1 part of tert-butanol, 1.5 parts of isobutanol, 15 parts of kerosene, 30 parts of coal clean oil and 40 parts of heavy aromatics After that, the finished product is obtained. The performance indicators of the obtained vehicle compound diesel oil are shown in Table 1.

Embodiment 2

[0013] The composite diesel for vehicles of the present embodiment is made up of the following components in parts by weight: ferrocene: 0.09 parts, diesel oil: 25 parts, dimethyl carbonate: 4 parts, tert-butanol: 1 part, isobutanol : 2 parts, kerosene: 20 parts, coal clean oil: 35 parts, 45 parts of heavy aromatics.

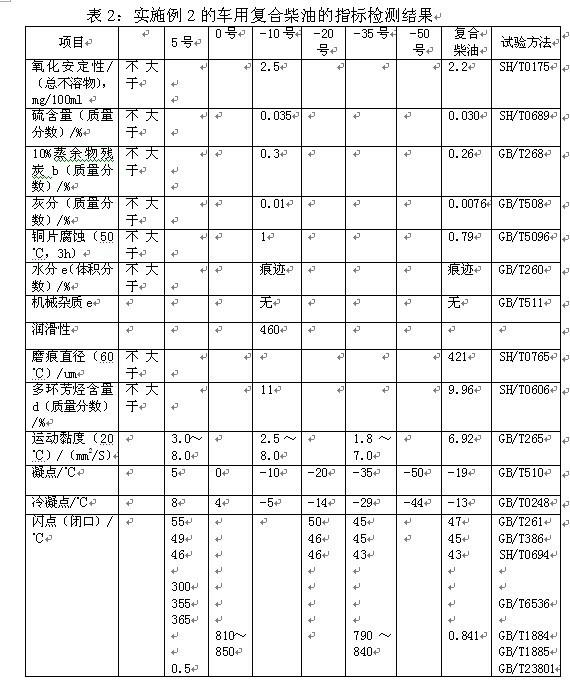

[0014] Preparation method: Physically mix 0.09 parts of ferrocene, 25 parts of diesel oil, 4 parts of dimethyl carbonate, 1 part of tert-butanol, 2 parts of isobutanol, 20 parts of kerosene, 35 parts of coal clean oil and 45 parts of heavy aromatics After that, the finished product is obtained. The performance indexes of the obtained compound diesel oil for vehicles are shown in Table 2.

Embodiment 3

[0016] The composite diesel for vehicles of the present embodiment is made up of the following components in parts by weight: ferrocene: 0.06 part, diesel oil: 22 parts, dimethyl carbonate: 3 parts, tert-butanol: 1 part, isobutanol : 1 part, kerosene: 15 parts, coal clean oil: 28 parts, 40 parts of heavy aromatics.

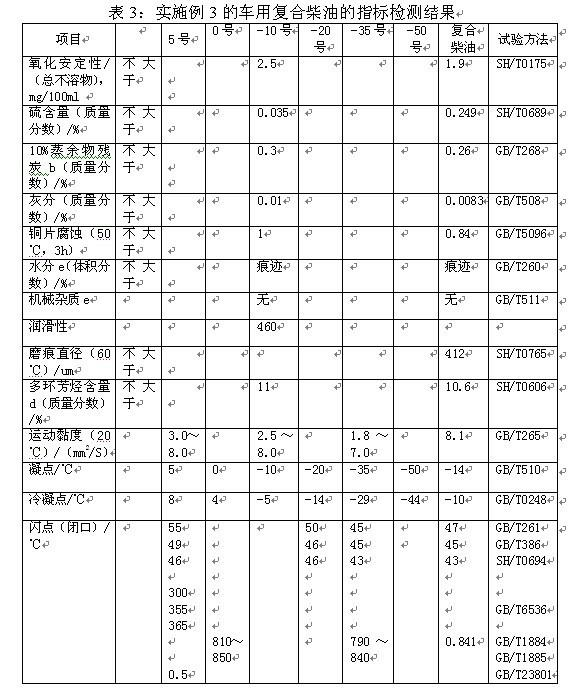

[0017] Preparation method: Physically mix 0.06 parts of ferrocene, 22 parts of diesel oil, 3 parts of dimethyl carbonate, 1 part of tert-butanol, 1 part of isobutanol, 15 parts of kerosene, 28 parts of coal clean oil and 40 parts of heavy aromatics After that, the finished product is obtained. The performance indexes of the obtained compound diesel oil for vehicles are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com