Thermosetting plastic used for underground installation and preparation method thereof

An underground facility, thermosetting technology, applied in the field of thermosetting plastics, can solve the problems of inconvenient construction, structural collapse, long construction period, etc., and achieve the effects of convenient maintenance and replacement, prevention of smoke, and low water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

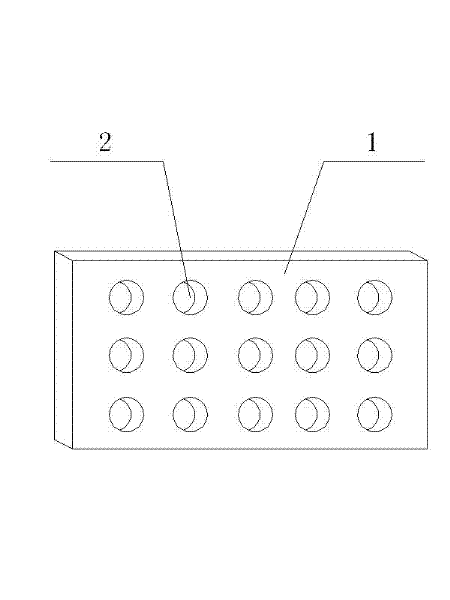

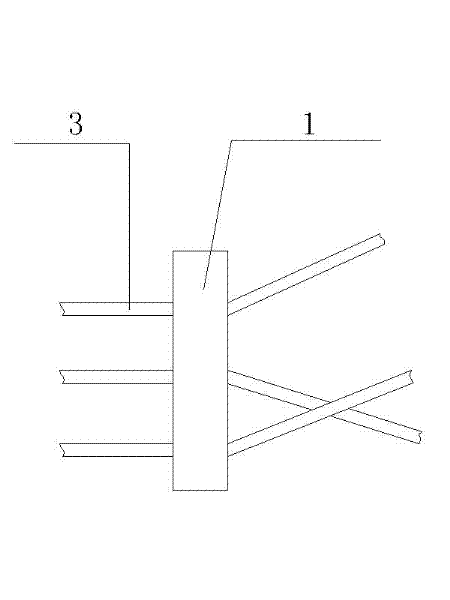

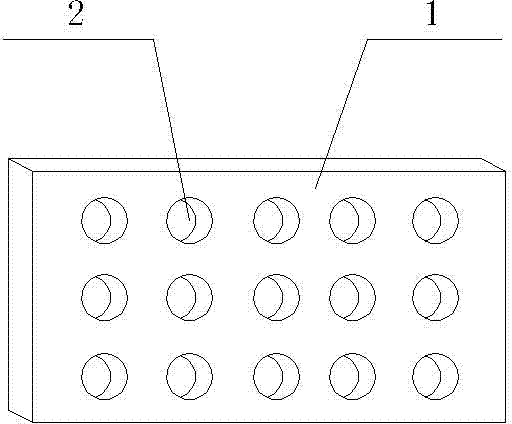

Image

Examples

Embodiment

[0061] Example 2: Low calorific value thermosetting plastics (LCTC) for underground facilities with different content of process additives

[0062] For different types of inorganic minerals, the addition amount has a great influence on the calorific value of thermosetting plastics, and the particle size directly affects the addition amount of inorganic minerals.

[0063] (1) Weigh the components according to the formula:

[0064] 100 parts of phenolic resin

[0065] Zinc stearate powder 10 parts

[0066] 100μm aluminum hydroxide powder 450 parts

[0067] 3 parts tert-butyl peroxybenzoate

[0068] Magnesium oxide 0.8 parts

[0069] D540 15 copies

[0070] Continuous glass fiber 250 parts

[0071] Measure phenolic resin, D540, zinc stearate micropowder, tert-butyl peroxybenzoate, and aluminum hydroxide micropowder, add them in a high-speed disperser in an orderly manner and mix and disperse for 30 minutes, then measure the thickener and mix and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com