Fully-degradable ratproof garbage bag and preparation method thereof

A fully degradable, garbage bag technology, applied in the field of polymer materials, can solve the problems of edible biological damage, secondary pollution, white pollution of non-degradable garbage bags, etc., to reduce material costs, increase interface bonding, maintain The effect of total biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

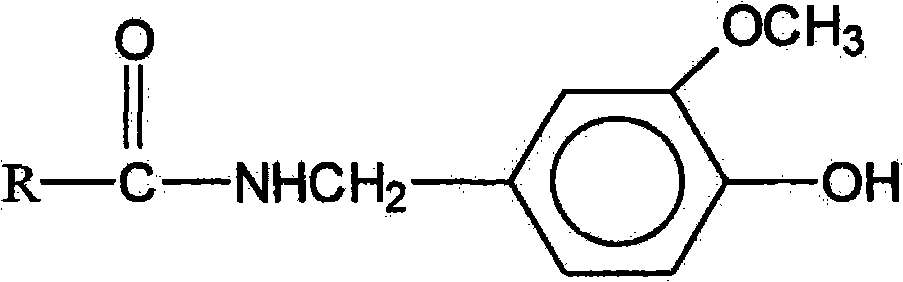

[0040] 30 parts by mass of polyterephthalic acid / adipate / butylene glycol, 10 parts by mass of polylactic acid, 30 parts by mass of cornstarch, 10 parts by mass of glycerin, 2 parts by mass of BASF chain extender JONCRYL ADR-4368, 8 Parts by mass of nonanoyl vanillyl amide and 10 parts by mass of light calcium carbonate are mixed uniformly in a high-speed mixer, and then the mixture is mixed in a twin-screw extruder, and the temperature of each section of the twin-screw extruder is set to T 1 =150°C, T 2 =160°C, T 3 =180°C, T 4 =200°C, T 5 =205°C, T 6 =210°C, twin-screw extruder speed R=300r·min -1 ; After that, extrude, cool, and granulate to obtain the bio-based material for the fully degradable rat-proof garbage bag; and then cooperate with the color masterbatch to obtain the fully-degradable rat-proof garbage bag through secondary processing, and its performance is as follows:

[0041]

Embodiment 2

[0043] 60 parts by mass of polyterephthalic acid / adipate / butylene glycol, 10 parts by mass of polylactic acid, 10 parts by mass of tapioca starch, 5 parts by mass of ethylene glycol, 10 parts by mass of decanoyl vanillyl amide and 5 parts by mass of talcum powder Mix evenly in a high-speed mixer, then knead the mixture in a twin-screw extruder, and set the temperature of each section of the twin-screw extruder to T 1 =155°C, T 2 =165°C, T 3 =185°C, T 4 =205°C, T 5 =215°C, T 6 = 220°C, twin-screw extruder speed R = 300r·min -1 ; After that, extrude, cool, and granulate to obtain the bio-based material for the fully degradable rat-proof garbage bag; and then cooperate with the color masterbatch to obtain the fully-degradable rat-proof garbage bag through secondary processing, and its performance is as follows:

[0044]

Embodiment 3

[0046]30 parts by mass of polyterephthalic acid / adipate / butylene glycol, 30 parts by mass of polylactic acid, 10 parts by mass of cornstarch, 5 parts by mass of propylene glycol, 5 parts by mass of octanoyl vanillyl amide and 20 parts by mass of light calcium carbonate Mix evenly in a high-speed mixer, then knead the mixture in a twin-screw extruder, and set the temperature of each section of the twin-screw extruder to T 1 =145°C, T 2 =155°C, T 3 =165°C, T 4 =180°C, T 5 =195°C, T 6 = 205°C, twin-screw extruder speed R = 300r·min -1 ; After that, extrude, cool, and granulate to obtain the bio-based material for the fully degradable rat-proof garbage bag; and then cooperate with the color masterbatch to obtain the fully-degradable rat-proof garbage bag through secondary processing, and its performance is as follows:

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com