Thermosetting epoxy resin composition and epoxy fiberglass cloth-based copper clad laminate prepared from same

An epoxy glass fiber cloth, epoxy resin technology, applied in synthetic resin layered products, glass/slag layered products, layered products, etc., can solve the problems of resin fracture, brittleness, wire fracture, etc. The effect of increased sexual performance and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Isocyanate modified epoxy resin, 100 parts by weight;

[0037] Dicyandiamide (electronic grade), 2.64 parts by weight;

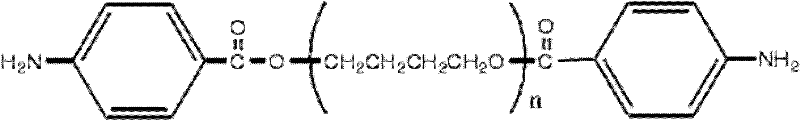

[0038] Poly-1,4-butanediol bis(4-aminobenzoate) (n=7) 10 parts by weight;

[0039] 2-methylimidazole, 0.05 parts by weight.

Embodiment 2

[0041] Isocyanate modified epoxy resin, 100 parts by weight;

[0042] Dicyandiamide (electronic grade) 2.64 parts by weight;

[0043] Poly-1,4-butanediol bis(4-aminobenzoate) (n=72) 10 parts by weight;

[0044] 2-methylimidazole, 0.05 parts by weight.

Embodiment 3

[0046]Isocyanate modified epoxy resin, 100 parts by weight;

[0047] Dicyandiamide (electronic grade) 2.64 parts by weight;

[0048] Poly-1,4-butanediol bis(4-aminobenzoate) (n=14) 10 parts by weight;

[0049] 2-methylimidazole, 0.05 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com