Crosslinked polymer microspheres and preparation method thereof

A technology of cross-linking polymers and microspheres, used in the petroleum industry, can solve the problems of reducing the economy of the injection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, the preparation of cross-linked polymer microspheres

[0026] Add 1.50 grams of polyvinylpyrrolidone (K-60), 16.50 grams of ammonium sulfate, 1.50 grams of sodium chloride, and 5.68 grams of acrylamide (AM) in a jacketed reactor equipped with a gas inlet pipe, a thermometer, and a constant speed stirrer , sodium acrylate 1.02 g, 2-acrylamide-2-methylpropanesulfonic acid (AMPS) 3.30 g, N,N'-diallyl-N,N,N',N'-tetramethylhexanedichloride 0.45 g of ammonium chloride, 0.50 mg of disodium edetate as a chelating agent, and 1.0 mg of cosolvent urea, all the above ingredients were dissolved in 68.00 g of ultrapure water (conductivity ≤ 4 μS / cm), and mixed with 35% sodium hydroxide Adjust the pH value of the solution to 7.5-8.5; in the above water dispersion, the mass percentage of ammonium sulfate and sodium chloride is 18.0%; the mass percentage of acrylamide is 5.68%; polyvinylpyrrolidone, sodium acrylate and 2- The mass percent of acrylamide-2-methylpropanesulf...

Embodiment 2

[0030] Embodiment 2, the preparation of cross-linked polymer microspheres

[0031] Add 2.50 grams of polyvinylpyrrolidone (K-17), 17.50 grams of ammonium sulfate, 1.50 grams of sodium chloride, and 5.68 grams of acrylamide (AM) in a jacketed reactor equipped with a gas inlet pipe, a thermometer, and a constant speed stirrer , sodium acrylate 1.02 g, 2-acrylamide-2-methylpropanesulfonic acid (AMPS) 3.30 g, N,N'-diallyl-N,N,N',N'-tetramethylhexanedichloride 0.45 grams of ammonium chloride, 0.50 milligrams of disodium edetate as a chelating agent, and 1.0 milligrams of urea. The above ingredients were dissolved in 66.00 grams of ultrapure water (conductivity ≤ 4 μS / cm), and the solution was adjusted with 35% sodium hydroxide The pH is 7.5-8.5. In the above aqueous dispersion, the mass percentage of ammonium sulfate and sodium chloride is 19.0%; the mass percentage of acrylamide is 5.68%; polyvinylpyrrolidone, sodium acrylate and 2-acrylamide-2-methylpropanesulfonate The mass pe...

Embodiment 3

[0035] Embodiment 3, the preparation of cross-linked polymer microspheres

[0036] The crosslinked polymer microsphere aqueous solution powder was prepared according to the same method as in Example 1.

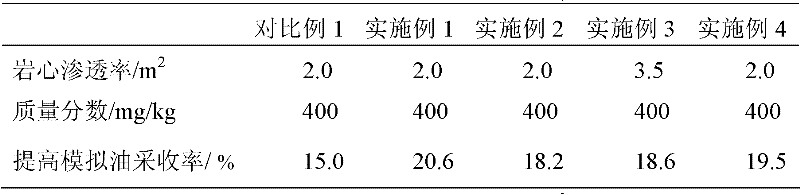

[0037] The above-prepared cross-linked polymer microspheres with a mass fraction of 400 mg / kg were aged in simulated water of Bohai SZ36-1 oilfield at 60°C for 96 hours to obtain an aqueous solution of cross-linked polymer coils, with a gas permeability of 3.5 μm 2 The simulated oil displacement experiment of the Bohai SZ36-1 oilfield was carried out on artificial cores, and it was measured that the simulated oil recovery could be increased by 18.6% under the experimental conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com