Anode Sn-Ru-Ir/TiO2 nano-particle catalyst for seawater electrolytic reaction and preparation method thereof

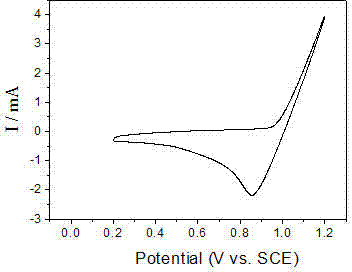

A nanoparticle, electrolytic reaction technology, applied in the field of anode catalyst and its preparation, can solve the problems of high material cost, easy loss of active component life, limited service life, etc., and achieve simple preparation method, excellent electrocatalytic activity and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Sn-Ru-Ir / TiO in Seawater Electrolysis 2 The anode nanoparticle catalyst is prepared by a stepwise homogeneous precipitation method, comprising the following steps:

[0031] 1. Weigh 60 mg of synthesized titanium dioxide nanoparticles, add 0.01468 g of SnCl 4 ·5H 2 O, 5ml 0.067mol / L RuCl 3 2H 2 O, 7.5ml 0.067mol / L IrCl 3 ·H 2 O solution, then adjust the pH value of the mixture solution step by step from 1 to 1.7-2.5, heat at 80-100°C for 10min-2h; further adjust the pH value of the solution to 3-4, and heat at 80-100°C for 10min-2h; finally adjust the solution pH value to 9-10, heating at 80-100°C for 10min-2h, high-speed stirring (or ultrasonic oscillation) for 30 minutes to 48 hours to make the mixture uniform (component A).

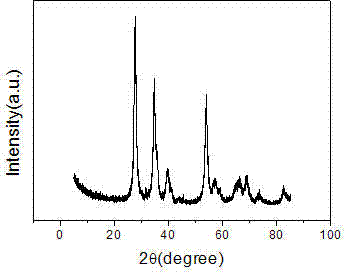

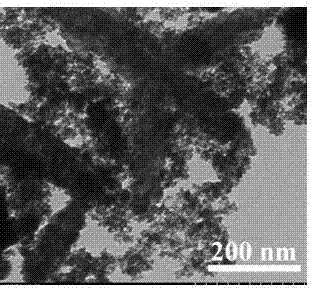

[0032] 2. After washing the obtained component A with water, in 60-80 o C is dried, and calcined at 350-800° C. in air for 0.5-1 h to obtain solid powder B; that is, to obtain a nanoparticle catalyst supported by a titanium dioxide nanocar...

Embodiment 2

[0036] Sn-Ru-Ir / TiO in Seawater Electrolysis 2 The anode nanoparticle catalyst is prepared by a stepwise homogeneous precipitation method, comprising the following steps:

[0037] 1. Weigh 60 mg of synthesized titanium dioxide nanotubes, add 0.01468 g of SnCl 4 ·5H 2 O, 5ml 0.067mol / L RuCl 3 2H 2 O, 7.5ml 0.067mol / L IrCl 3 ·H 2 O solution, then adjust the pH value of the mixture solution step by step from 1 to 1.7-2.5, heat at 80-100°C for 10min-2h; further adjust the pH value of the solution to 3-4, and heat at 80-100°C for 10min-2h; finally adjust the solution pH value to 9-10, heating at 80-100°C for 10min-2h, high-speed stirring (or ultrasonic oscillation) for 30 minutes to 48 hours to make the mixture uniform (component A).

[0038] 2. After washing the obtained component A with water, 60-80 o C is dried, and calcined at 350-800° C. in air for 0.5-1 h to obtain solid powder B; that is, to obtain a nanoparticle catalyst supported by a titanium dioxide nanocarrier. ...

Embodiment 3

[0042] Sn-Ru-Ir / TiO in Seawater Electrolysis 2 The anode nanoparticle catalyst is prepared by a stepwise homogeneous precipitation method, comprising the following steps:

[0043] 1. Weigh 60 mg of synthesized titanium dioxide nanofibers, add 0.01468 g of SnCl 4 ·5H 2 O, 5ml 0.067mol / L RuCl 3 2H 2 O, 7.5ml 0.067mol / L IrCl 3 ·H 2 O solution, then adjust the pH value of the mixture solution step by step from 1 to 1.7-2.5, heat at 80-100°C for 10min-2h; further adjust the pH value of the solution to 3-4, and heat at 80-100°C for 10min-2h; finally adjust the solution pH value to 9-10, heating at 80-100°C for 10min-2h, high-speed stirring (or ultrasonic oscillation) for 30 minutes to 48 hours to make the mixture uniform (component A).

[0044] 2. After washing the obtained component A with water, 60-80 o C is dried, and calcined at 350-800° C. in air for 0.5-1 h to obtain solid powder B; that is, to obtain a nanoparticle catalyst supported by a titanium dioxide nanocarrier. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com