Composite additive for negative electrode of lead-acid storage battery and its preparation and use method

A composite additive, lead-acid battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of insufficient battery charge acceptance and low-temperature discharge performance, huge impact on battery performance, and many types of negative electrode additives. , to achieve the effect of improving charging acceptance and low-temperature discharge performance, easy to use, and avoiding production and operation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

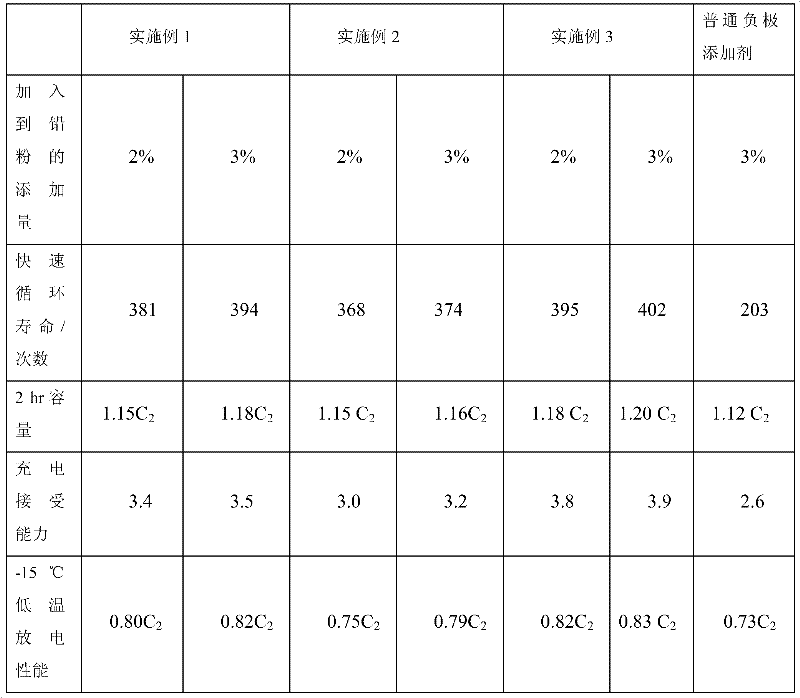

Embodiment 1

[0017] Mix raw materials according to mass percentage: 5% oak extract, 5% sodium lignosulfonate, 15% humic acid, 10% carbon black, 30% barium sulfate, tetrabasic lead sulfate with a median particle size of 3.5 μm 35%. Put the mixed material into the ball mill at a speed of 60r / min, mix for 3 hours, and pack the material.

Embodiment 2

[0019] Mix raw materials according to mass percentage: 10% oak extract, 8% sodium lignosulfonate, 15% humic acid, 10% carbon black, 25% barium sulfate, tetrabasic lead sulfate with a median particle size of 1.5 μm 32%. Put the mixed material into the ball mill at a speed of 60r / min, mix for 2 hours, and pack the material.

Embodiment 3

[0021] Mix the raw materials according to mass percentage: 15% of oak extract, 8% of sodium lignosulfonate, 15% of humic acid, 5% of carbon black, 20% of barium sulfate, tetrabasic lead sulfate with a median particle size of 1.0 μm 37%. Put the mixed material into the ball mill at a speed of 60r / min, mix for 4 hours, and pack the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com