A Soft Measurement Method for the Remaining Length of Electroslag Furnace Melting Electrode

A technology of remaining length and melting electrodes, which is applied in the direction of measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation of the device of the present invention will be described in detail below.

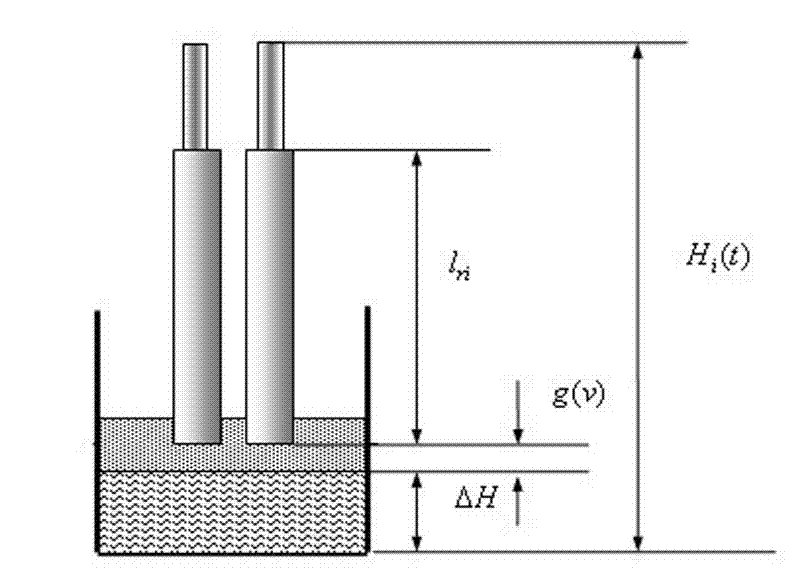

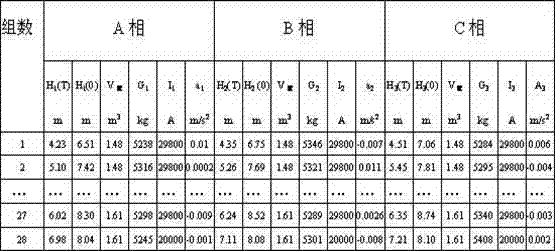

[0050] The present invention is specifically implemented by taking a three-phase six-electrode 120-ton electroslag furnace as a trial object. The cross arm of each phase clamps two electrodes, and the lifting of the electrodes is driven by a hydraulic cylinder, which is equipped with a position ruler to detect the stroke. A load cell is installed at the cross arm to measure the weight of the two electrodes. Since the circuit design can ensure that the melting length and speed of the two electrodes are equal, the two electrodes are regarded as one electrode. Each phase current is detected by a current transformer. The amount of slag added is weighed in advance and the volume is measured.

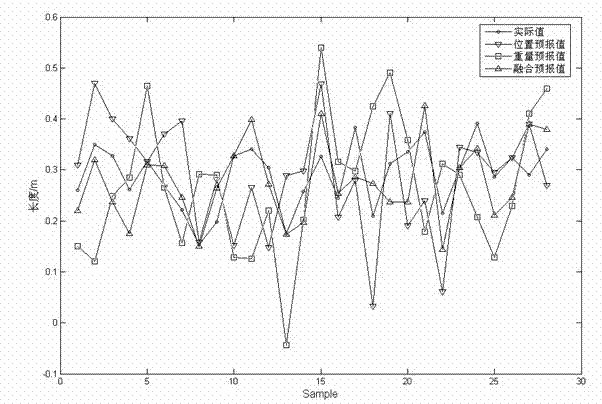

[0051] Record the initial weight of the load cell after clamping the electrode each time, then the electrode drops, arcing, and the current reaches the set value, and the initial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com