Composite black porcelain solar heat collecting plate and production method thereof

A solar collector and composite black technology, which is applied to solar thermal power generation, solar thermal devices, ceramic layered products, etc. needs, the internal structure is firm, and the installation is easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

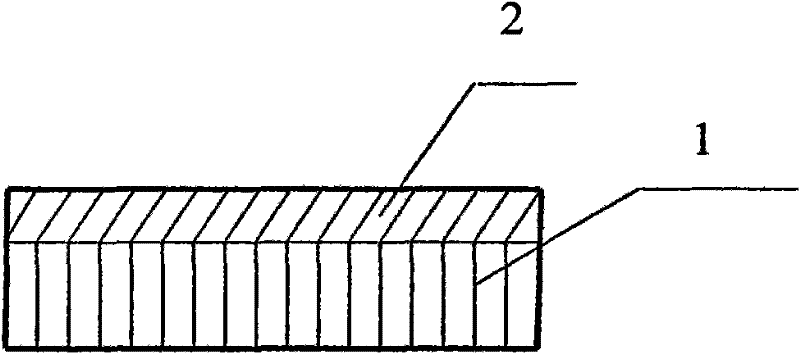

[0020] Composite black porcelain solar collector plate

[0021] See attached picture. A composite black porcelain solar heat collecting plate is characterized in that: the heat collecting plate is solid and consists of a common ceramic layer 1 and a black porcelain heat collecting layer 2, the common ceramic layer 1 is located on the base layer, and the black porcelain heat collecting layer 2 is located on the The surface layer, the base layer ordinary ceramic layer 1, and the surface layer black porcelain heat-collecting layer 2 are fired into one. Among them, the thickness of the ordinary ceramic layer on the base layer is 5-8mm, and the thickness of the black porcelain heat-collecting layer on the surface layer is 1-2mm.

[0022] The production process of the present embodiment is as follows:

[0023] (1) Preparation of common ceramic powder:

[0024] Use feldspar, clay, pyrophyllite, talc and other mineral raw materials to meet the following chemical composition (weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com