Full performance scroll compressor all-in-one machine

An air compressor and integrated machine technology, which is applied in the direction of machines/engines, rotary piston machines, components of pumping devices for elastic fluids, etc., can solve the problem of large pressure loss, high energy consumption of air compressors and high noise and other problems, to achieve the effect of reducing heat load, compact structure and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

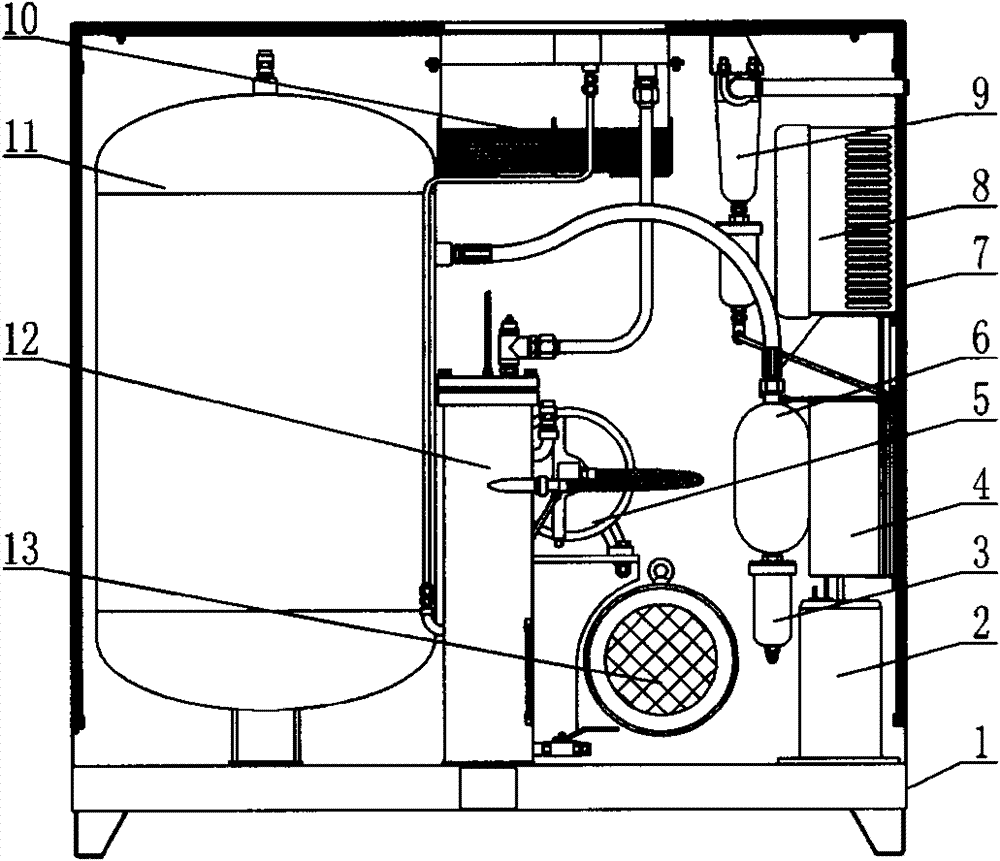

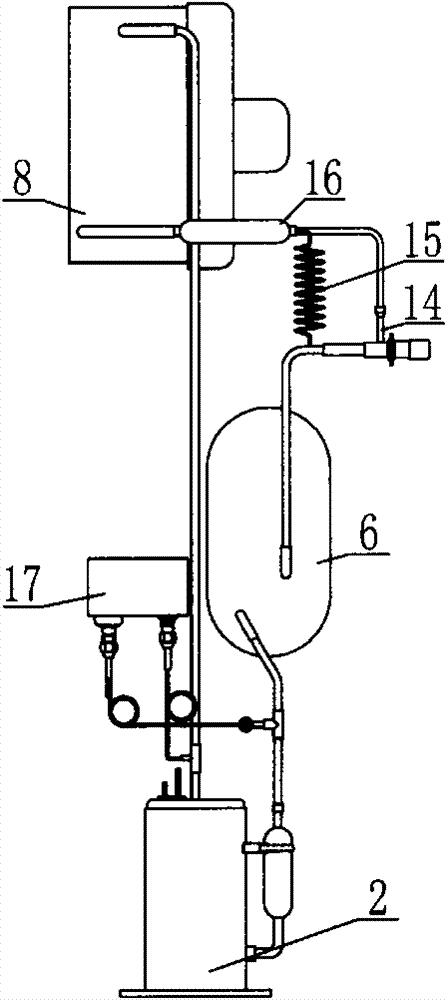

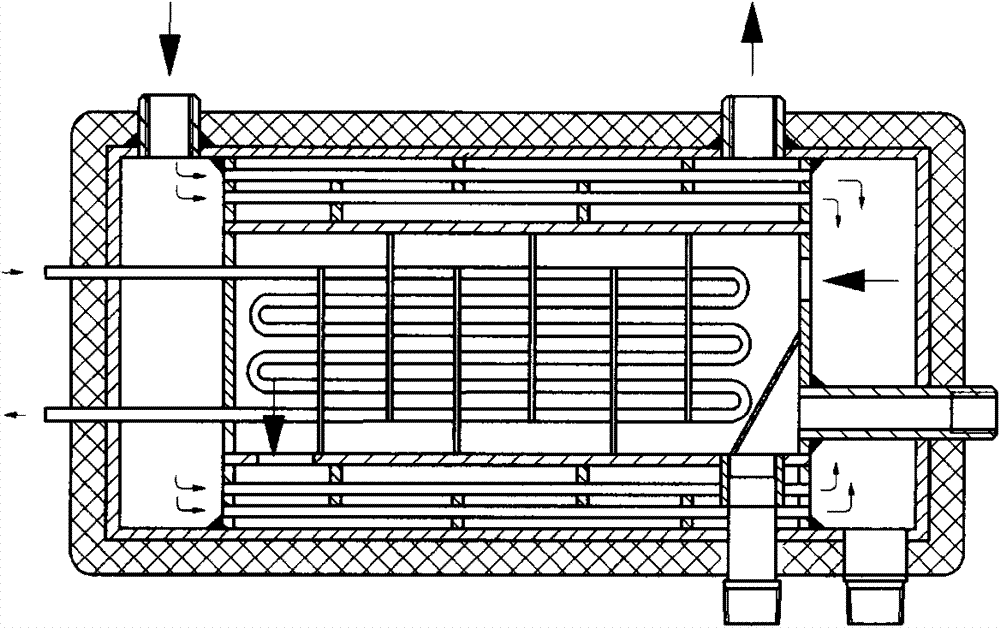

[0022] Reference figure 1 , figure 2 , image 3 , The full-performance scroll air compressor integrated machine consists of a chassis 1 and a refrigeration compressor installed in the chassis 2, an automatic drain 3, an electric control system 4, a scroll air compressor 5, an integrated pre-cooling evaporator 6, and sound absorption Sponge 7, air-cooled condenser 8, primary high efficiency filter 9, oil and gas cooler 10, gas storage tank 11, oil and gas separation tank 12, electric motor 13, bypass valve 14, throttle capillary 15, filter drier 16, high and low pressure Switch 17 and its pipeline composition.

[0023] The machine specifically includes a scroll air compressor system, an air storage system, a compressed air freeze-drying system, a precision filtering system and connecting pipes. The above-mentioned systems are integrated and installed in a chassis 1 with a sound-absorbing sponge 7 on the inner surface of the chassis.

[0024] The scroll air compressor system of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com