A kind of lubricity additive of low-sulfur diesel oil and preparation method thereof

A low-sulfur diesel and lubricity technology, used in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of lubricity and physical properties not reaching performance, and achieve the effect of easy availability of raw materials and huge application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In a 500ml four-necked reaction flask equipped with stirring and a thermometer, add 2mol methanol and 3.5g potassium hydroxide and stir to dissolve, then add 1mol safflower oil and heat up at 60°C for 2 hours. After the reaction is over, separate the excess methanol and Glycerin, the remaining methyl esters are rectified under vacuum, and 50g is distilled forward, and the remaining bottom liquid is added with 40g urea and 80g methanol, heated to dissolve, cooled to 0°C, kept for 12 hours, suction filtered, and methanol is recovered to obtain unsaturated fatty acid methyl Esters 110g.

[0026] Add 110 g of unsaturated fatty acid methyl esters, 150 g of glycerin, and 2.5 g of sodium hydroxide into a 500 ml four-neck reaction flask equipped with a stirring thermometer and heat at 200 ° C for 2 hours to react for 2 hours, then cool down to remove excess glycerin to obtain 120 g of fatty acid glycerides .

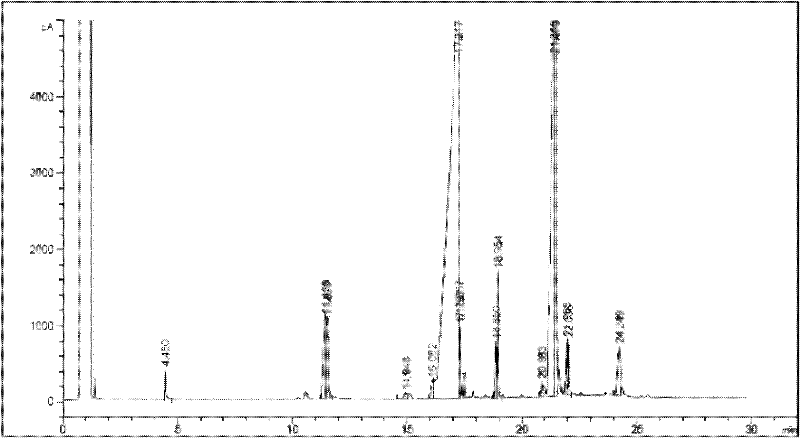

[0027] Below is the gas chromatographic analysis of the product, an...

Embodiment 2

[0033] In a 500ml four-necked reaction flask equipped with stirring and a thermometer, add 2mol of methanol and 3.5g of potassium hydroxide and stir to dissolve, then add 1mol of hempseed oil and heat up at 60°C for 2 hours. After the reaction, remove the excess methanol and Glycerin, the remaining methyl esters are rectified under vacuum, and 50g is distilled forward, and the remaining bottom liquid is added with 40g urea and 80g methanol, heated to dissolve, cooled to 0°C, kept for 12 hours, suction filtered, and methanol is recovered to obtain unsaturated fatty acid methyl Esters 110g.

[0034] Add 110 g of unsaturated fatty acid methyl esters, 150 g of glycerin, and 2.5 g of potassium hydroxide into a 500 ml four-necked reaction flask equipped with a stirring thermometer and heat at 200° C. for 2 hours, then cool down to remove excess glycerin to obtain 120 g of the product.

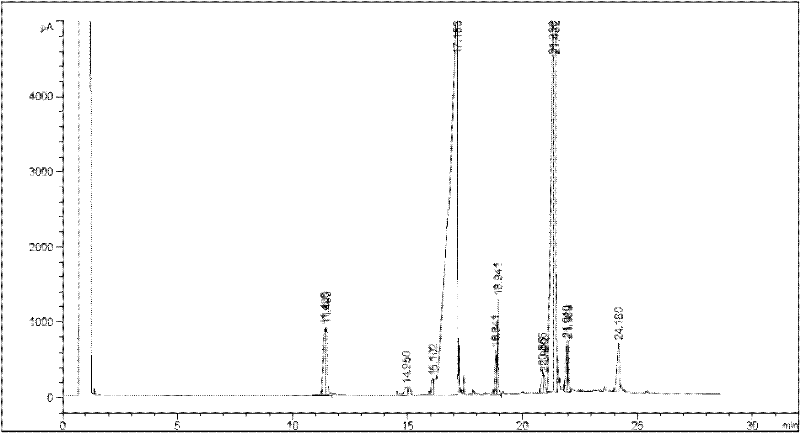

[0035] Below is the gas chromatographic analysis of the product, and the results are as follows. ...

Embodiment 3

[0040] Add 2 mol of methanol and 3.5 g of potassium hydroxide to a 500ml four-necked reaction flask equipped with a stirring and thermometer and stir to dissolve, then add 1 mol of cottonseed oil and heat up at 60°C for 2 hours. After the reaction, remove excess methanol and glycerin , the remaining methyl esters are rectified under reduced pressure, 60g is distilled forward, 40g urea and 80g methanol are added to the remaining bottom liquid, heated to dissolve, cooled to 0°C, kept for 12 hours, filtered with suction, and methanol is recovered to obtain unsaturated fatty acid methyl ester 100g.

[0041] Add 100 g of unsaturated fatty acid methyl esters, 150 g of glycerin, and 2.5 g of sodium hydroxide into a 500 ml four-neck reaction flask equipped with a stirring thermometer and heat at 200° C. for 2 hours, then cool down to remove excess glycerin to obtain 110 g of the product.

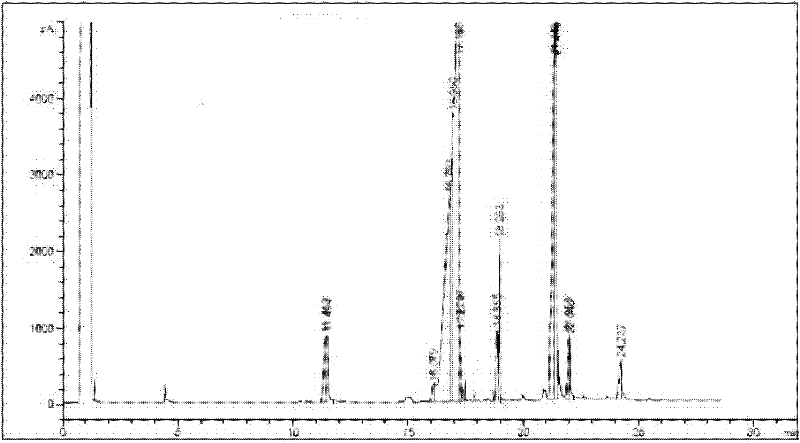

[0042] Below is the gas chromatographic analysis of the product, and the results are as follows....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com