Tungsten-doped vanadium dioxide nanopowder and preparation method thereof

A vanadium dioxide nanometer and vanadium dioxide technology, which is applied in the field of tungsten-doped vanadium dioxide nanopowder and its preparation, can solve the problems that affect the large-scale implementation of industrialization, the process is cumbersome, and the powder is difficult to apply. Large-scale industrial implementation, simple preparation method, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The concrete steps of preparation are:

[0027] Step 1, first follow the V 0.99 W 0.01 o 2 Weigh the corresponding amount of vanadium pentoxide and ammonium tungstate, mix them and place them at 830°C to melt and keep warm for 20 minutes. Then immerse the molten body in a quenching medium and stir for 12 hours, then leave it to age for 10 days; wherein, the quenching medium is deionized water (or distilled water) to obtain a doped sol.

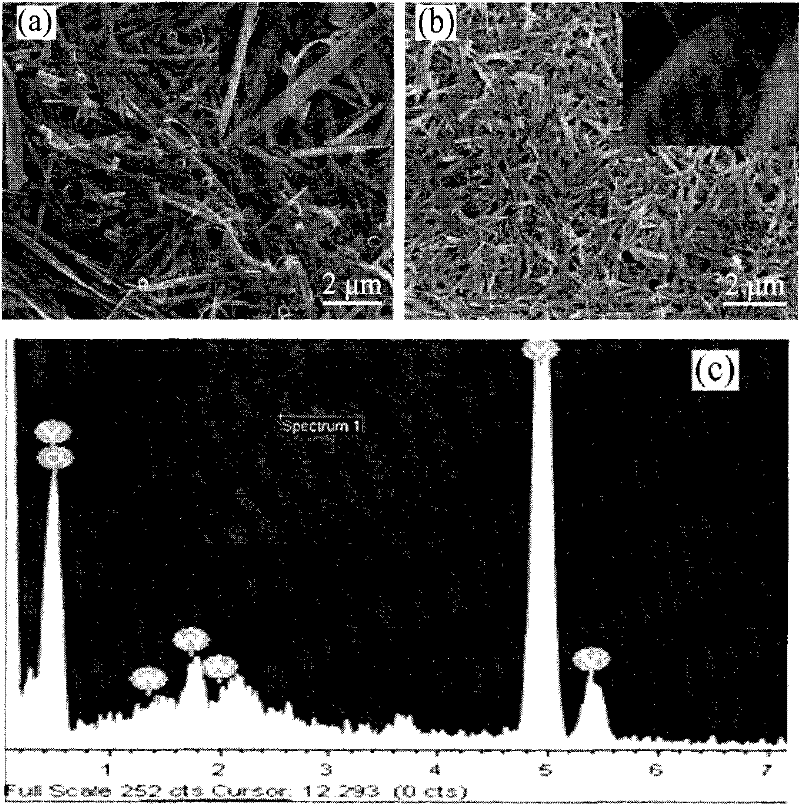

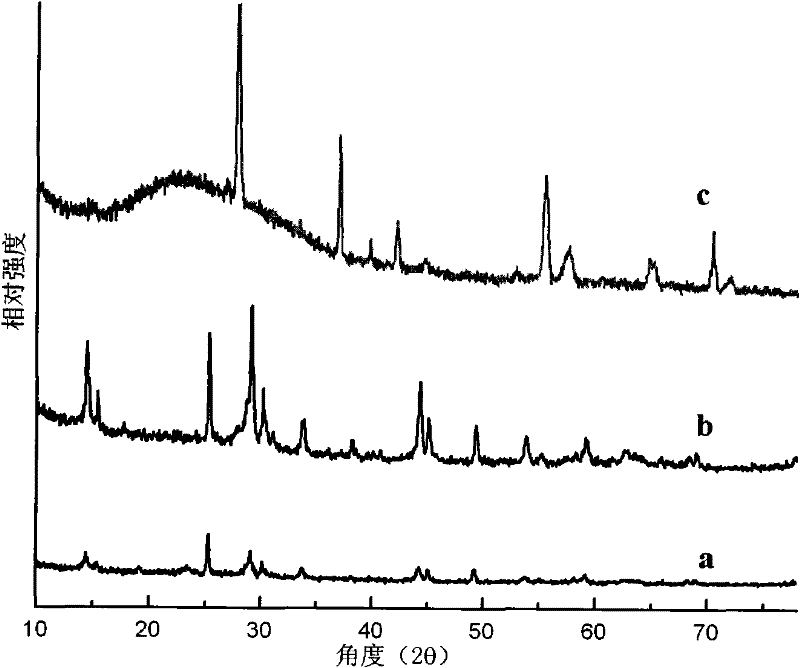

[0028] Step 2, first add the polyethylene glycol aqueous solution with a concentration of 23wt% into the doping sol, and stir for 8 hours; wherein, the volume ratio between the polyethylene glycol aqueous solution and the doping sol is 4:1, and the polyethylene glycol is polyethylene glycol-6000 to obtain a mixed solution. Then put the mixed solution in an airtight state, and conduct a hydrothermal reaction at 180°C for 2 days; figure 1 a. figure 2 a and figure 2 as shown in b, and as figure 1 c and image 3 The flake-like tu...

Embodiment 2

[0030] The concrete steps of preparation are:

[0031] Step 1, first follow the V 0.985 W 0.015 o 2 Weigh the corresponding amount of vanadium pentoxide and ammonium tungstate, mix them and place them at 840°C to melt and keep warm for 21 minutes. Then immerse the molten body in a quenching medium and stir for 13 hours, then leave it to age for 11 days; wherein, the quenching medium is deionized water (or distilled water) to obtain a doped sol.

[0032] Step 2, first add a polyethylene glycol aqueous solution with a concentration of 24wt% into the doping sol, and stir for 8.5 hours; wherein, the volume ratio between the polyethylene glycol aqueous solution and the doping sol is 3.8:1.3, polyethylene glycol For polyethylene glycol-6000, a mixed solution was obtained. Then the mixed solution was placed in a closed state, and hydrothermally reacted at 190°C for 3 days; figure 1 a. figure 2 a and figure 2 as shown in b, and as figure 1 c and image 3 The flake-like tung...

Embodiment 3

[0034] The concrete steps of preparation are:

[0035] Step 1, first follow the V 0.98 W 0.02 o 2 Weigh the corresponding amount of vanadium pentoxide and ammonium tungstate, mix them and place them at 850°C to melt and keep warm for 23 minutes. Then, the molten body was immersed in a quenching medium and stirred for 14 hours, and then aged for 12 days; wherein, the quenching medium was deionized water (or distilled water) to obtain a doped sol.

[0036] Step 2, first add the polyethylene glycol aqueous solution with a concentration of 25wt% into the doping sol, and stir for 9 hours; wherein, the volume ratio between the polyethylene glycol aqueous solution and the doping sol is 3.5:1.5, and the polyethylene glycol is polyethylene glycol-6000 to obtain a mixed solution. Then the mixed solution was placed in a closed state, and hydrothermally reacted at 200°C for 4 days; figure 1 a. figure 2 a and figure 2 b and / or figure 1 b. figure 2 c and figure 2 d, and as fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com