Manual loading and unloading mechanism of workpiece transfer device

A technology of conveying device and loading and unloading mechanism, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem of breakage of the workpiece holding hand 5 and the feeding rod, and achieve the effects of ensuring durability, reducing cost, and restraining breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Next, embodiments of the present invention will be described based on examples.

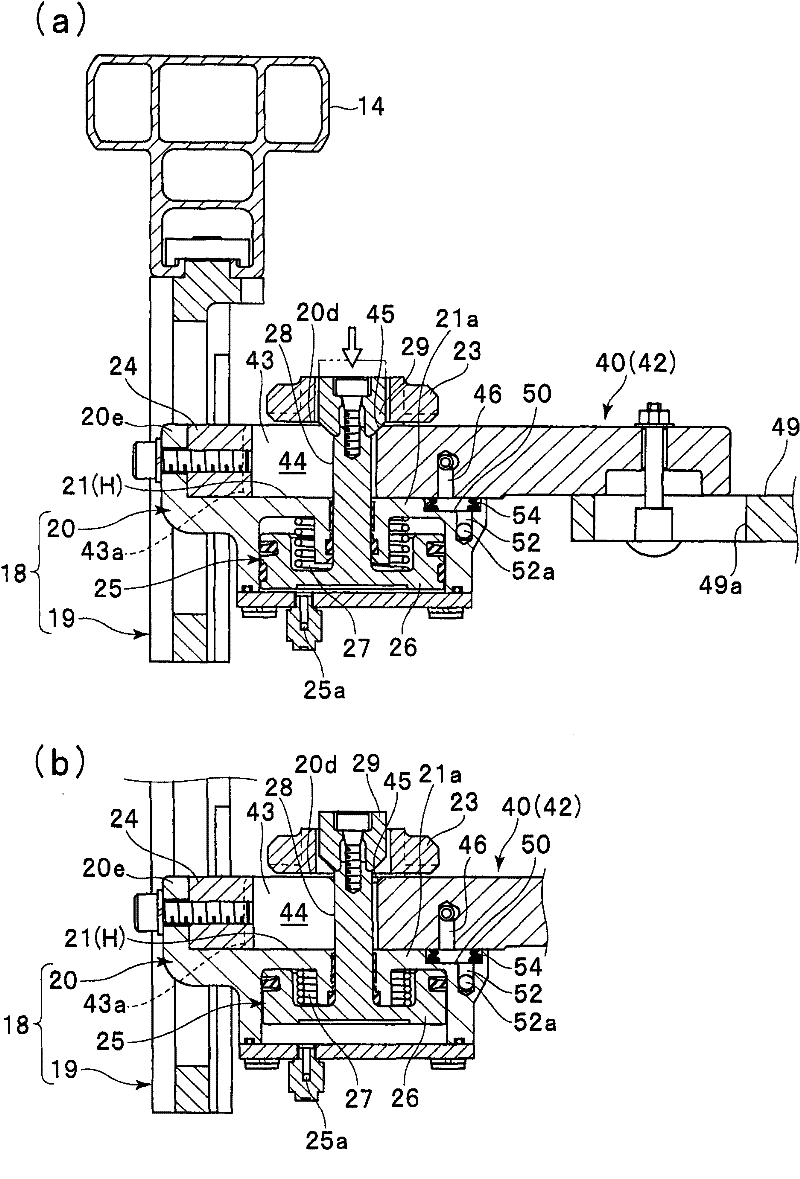

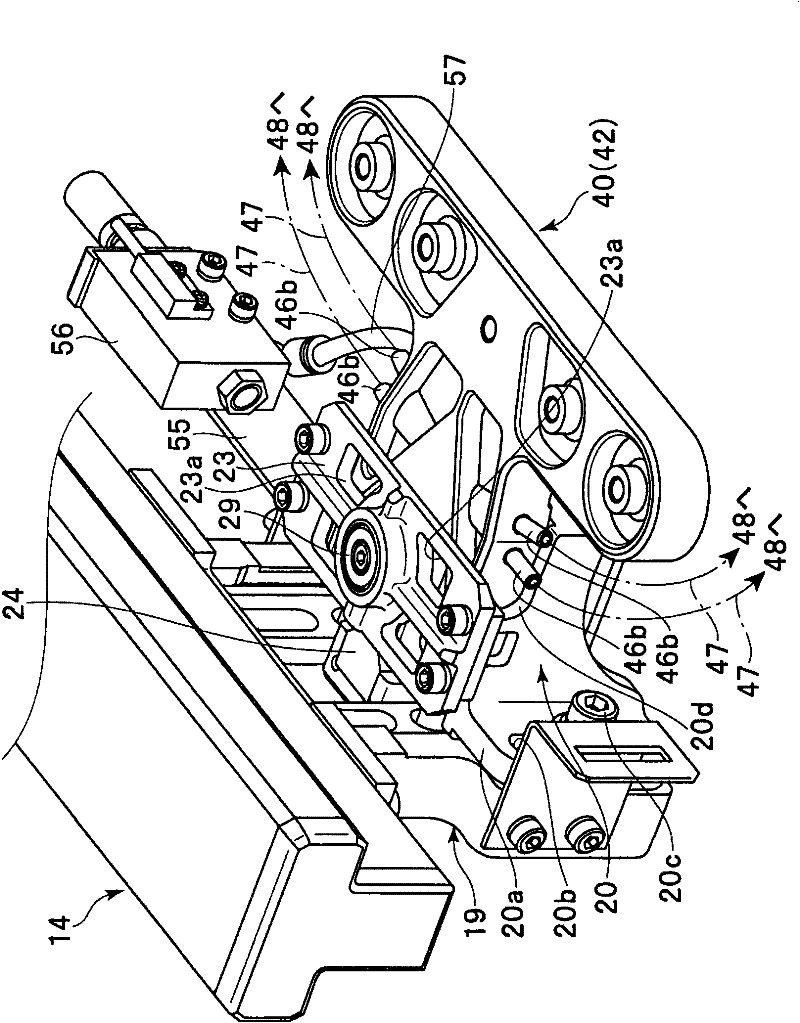

[0064] Figure 1 to Figure 10 A hand loading and unloading mechanism of a workpiece conveying device according to an embodiment of the present invention is shown, figure 1 is a front view of the entire workpiece transfer device, Figure 2 to Figure 8 The hand loading and unloading mechanism of this conveying device is shown.

[0065] exist figure 1 Among them, the workpiece transfer device 10 is the same as the above-mentioned conventional example. For example, it is configured as an industrial robot that is installed in the middle position of a pair of press processing machines (not shown) and moves from one (for example, figure 1 On the left side) the workpiece mounting table (not shown) of the press processing machine receives the workpiece, and transfers it to another (such as figure 1 Right) The workpiece loading table (not shown) of the press machine feeds the workpiece.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com