A kind of anti-icing riser welding method

A welding method and riser technology, applied in welding equipment, arc welding equipment, edge parts of workpieces, etc., can solve the problems of low weld metal fusion ratio, large residual stress in welds, waste of welding materials, etc., and achieve weld filling. Small volume, reduced welding workload, and small human influence factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

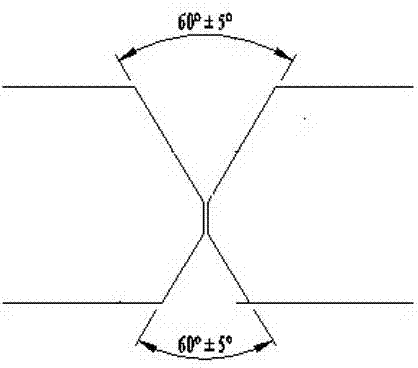

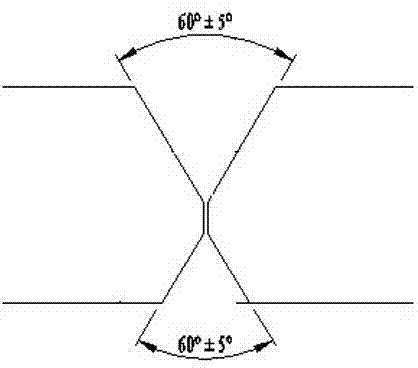

[0009] The invention relates to a welding method for an anti-icing riser, which changes the original V-shaped groove into a symmetrical X-shaped groove. The longitudinal seam and the circular seam welded with the joint are welded by internal and external submerged arc welding. The welded ring seam between the joint and the pipe body is firstly welded by the submerged arc welding operator to weld the inner seam, and the outer groove is filled after the outer root is cleaned and polished. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com