Microcrystal extrusion equipment and production method thereof

A technology of extrusion equipment and production method, applied in the field of continuous microcrystalline extrusion equipment, can solve the problem of inability to understand the operation mode of the microcrystalline extrusion equipment in a short time, a reliable and effective adjustment scheme, and the inability to complete the microcrystalline extrusion equipment well. problems such as debugging of crystal extrusion equipment, to achieve the effect of fine crystal particles, convenient operation and maintenance, and change of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

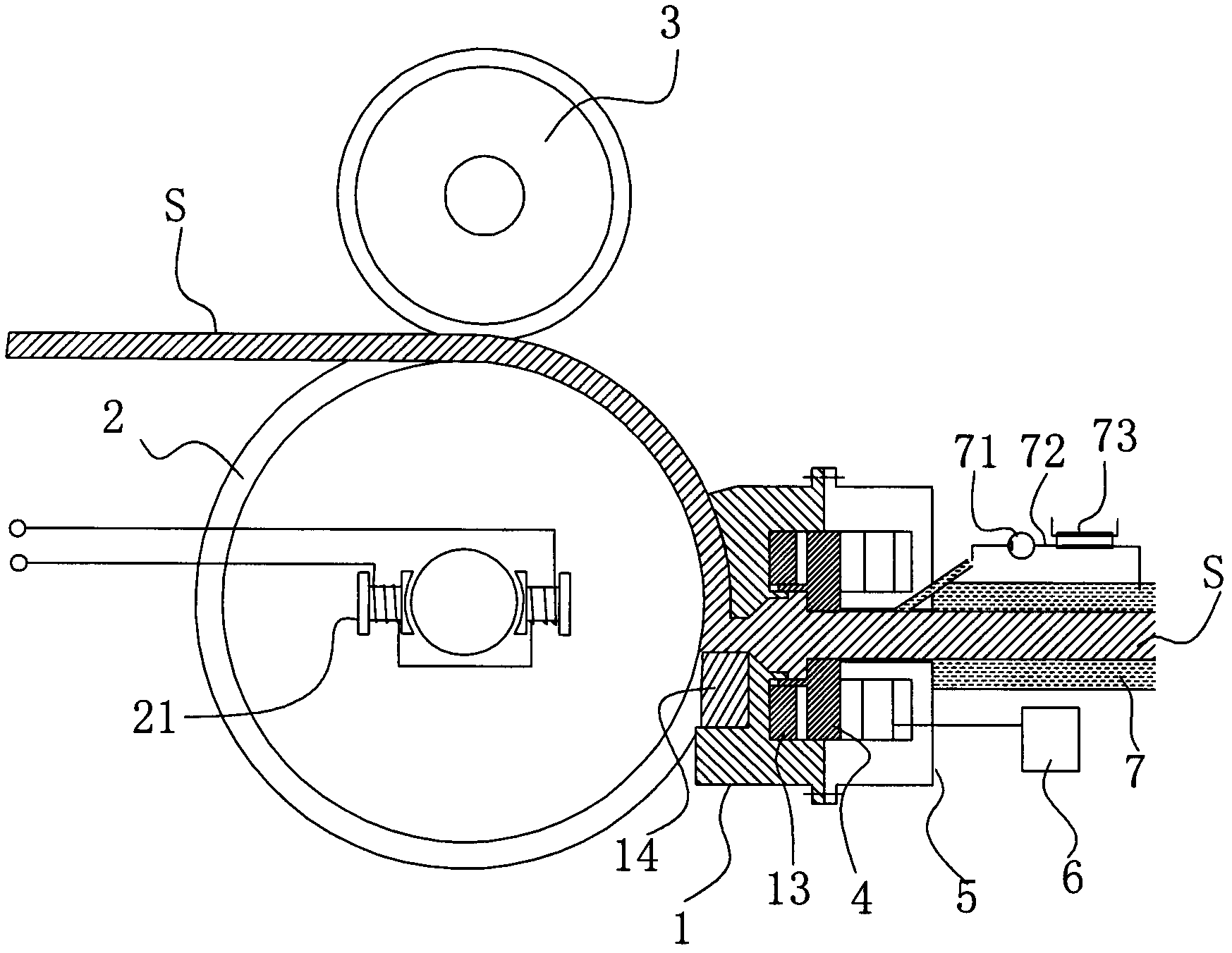

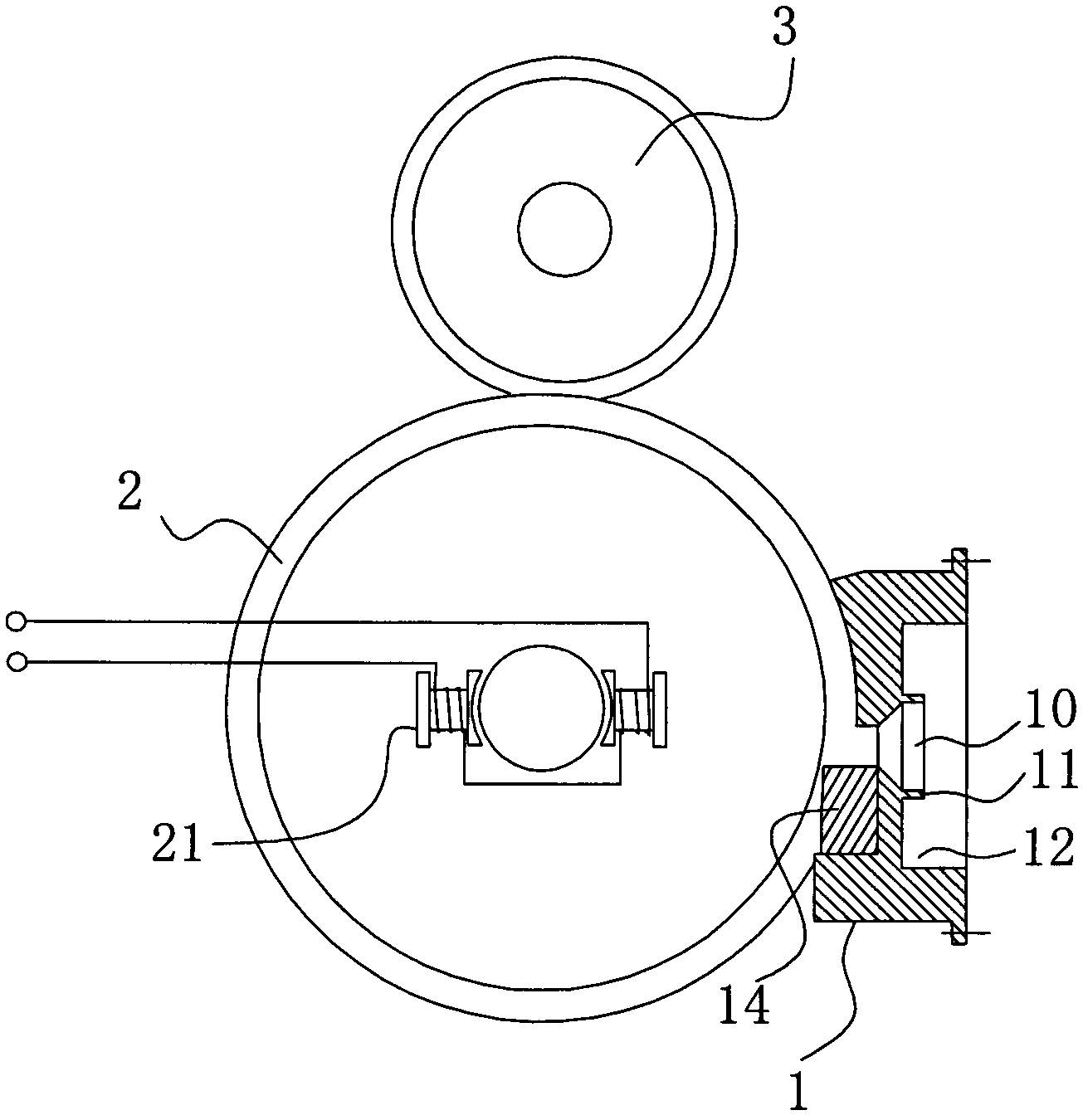

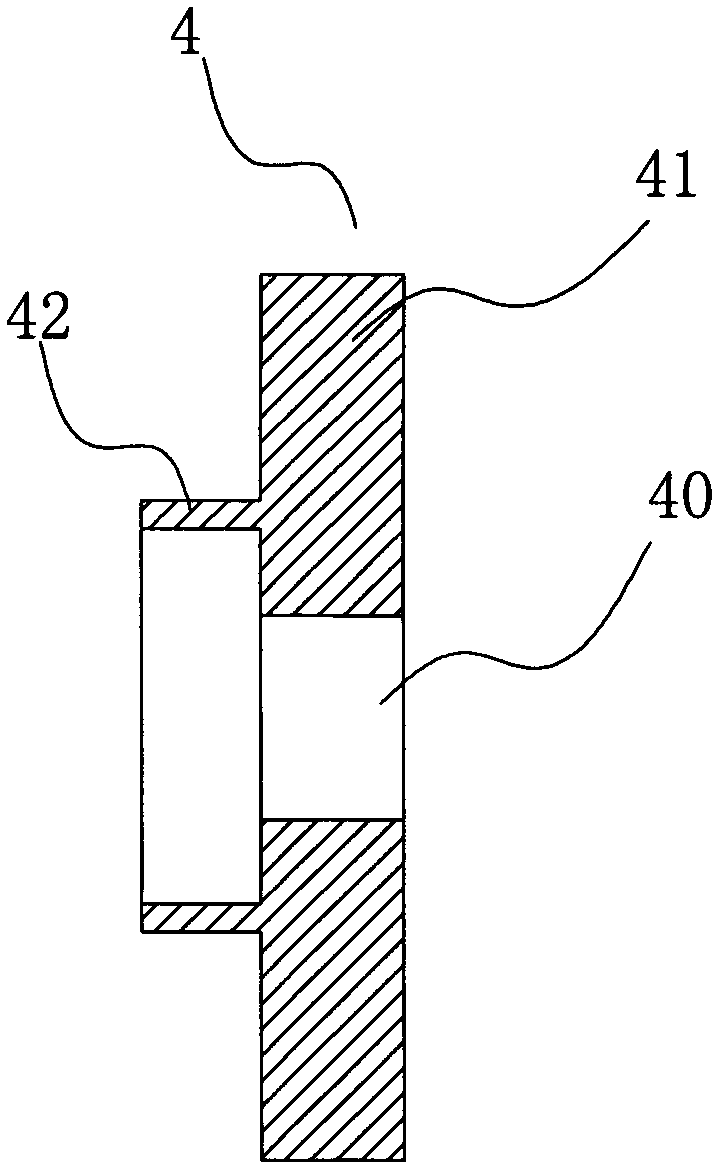

[0050] Such as figure 1 As shown, the microcrystal extrusion equipment of the present invention includes a machine base 1, an extrusion wheel 2 and a compacting wheel 3 arranged on the machine base 1, and an extrusion cavity 10 is also arranged in the machine base 1, and on the machine base 1 There is a movable mold 4 docked with the extrusion die cavity 10 and a power mechanism 5 for driving the movable mold 4, the power mechanism 5 is arranged at the extrusion end of the movable mold; the power mechanism 5 is provided with a The fixed end and the movable end that stop against the outside of the movable mold also include a power source 6 connected with the power mechanism 5 . In this embodiment, the base 1 is also provided with an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com