Barrel lining

A liner and cylinder technology, which is applied in the field of overflow ball mill cylinder liner, can solve the problems that affect the normal production of the mill, the volume of the cylinder liner is large, and the screw holes are broken, so as to facilitate installation and disassembly, improve Efficiency, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

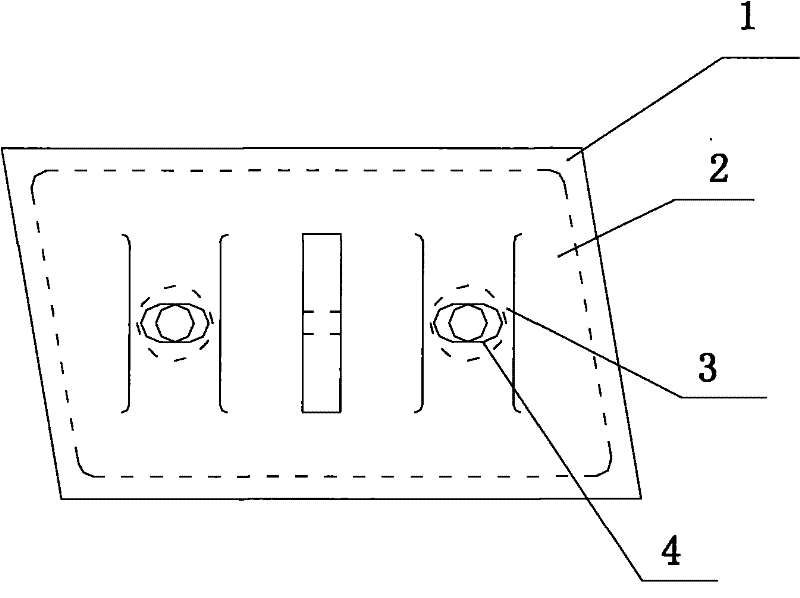

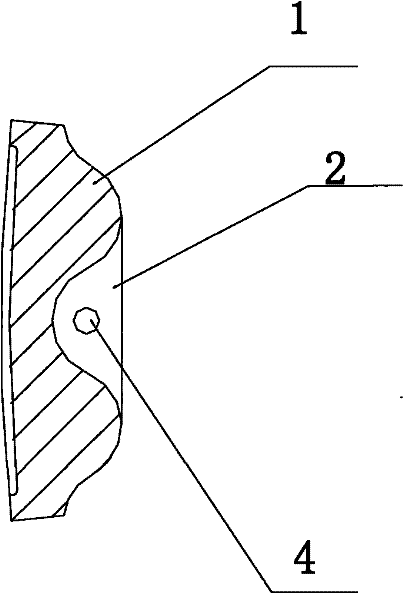

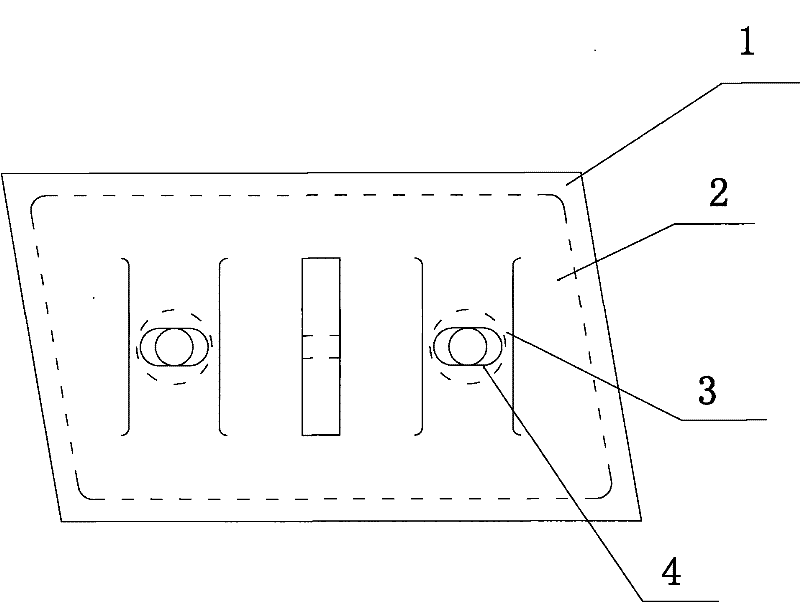

[0010] See Figure 1 to Figure 2 , the liner 1 is a parallelogram, the middle position of the liner 1 is equipped with a hoisting hole 4 parallel to the installation surface 2, and reinforcement 3 is provided around the hoisting hole 4.

[0011] Apparently, the above-mentioned embodiments of the present invention are only examples for clearly illustrating the present invention, rather than limiting the implementation of the present invention. For those of ordinary skill in the art, other changes or changes in different forms can be made on the basis of the above description. It is not necessary and impossible to exhaustively list all the implementation modes here, and the obvious changes or modifications derived from the spirit of the present invention are still within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com