Low-temperature composite electrothermal material and its preparation method

An electrothermal material and low temperature technology, applied in the field of low temperature composite electrothermal material and its preparation, can solve the problems of low working life, scrapped heating layer, large contact resistance and gap, etc., and achieve the effect of fast heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

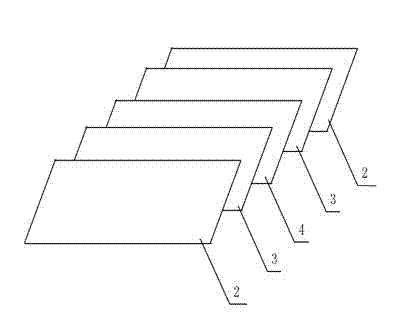

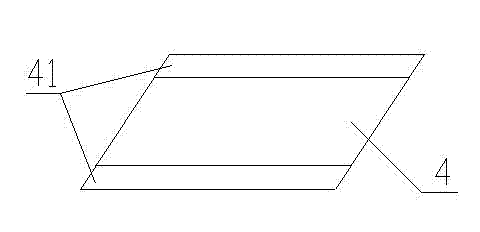

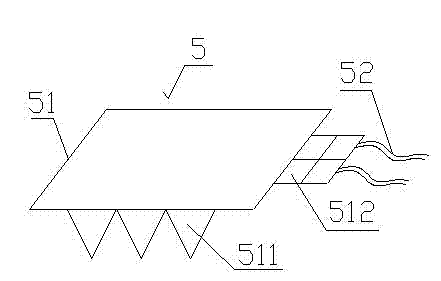

[0057] Please see attached figure 1 - attached Figure 10 As shown, the preparation method of the low-temperature composite electrothermal material of the present invention includes the following steps:

[0058] Step 1, prepare epoxy resin glass fiber cloth 3. Epoxy glass fiber cloth 3 is prepared by mixing 2124 phenolic resin, 6101 epoxy resin, 706 water-based polyurethane resin, silane coupling agent, acetone solution and alkali-free glass fiber cloth in a certain proportion.

[0059] Step 1.1, mix 2124 phenolic resin and 6101 epoxy resin evenly to make the first mixed solution. The mixing ratio range of 2124 phenolic resin and 6101 epoxy resin is 3-5.5:1.

[0060] Step 1.2, uniformly mix the first mixed solution prepared in step 1.1 with 706 water-based polyurethane resin to prepare the second mixed solution. The mixing ratio range of the first mixed solution to 706 waterborne polyurethane resin is 15-25:1.

[0061] Step 1.3, uniformly mix the acetone solution and the ...

Embodiment 1

[0076] The low-temperature composite electric heating material is prepared by the following method:

[0077] Step 1, prepare epoxy resin glass fiber cloth 3. Epoxy glass fiber cloth 3 is prepared by mixing 2124 phenolic resin, 6101 epoxy resin, 706 water-based polyurethane resin, silane coupling agent, acetone solution and alkali-free glass fiber cloth according to the following ratio.

[0078] Step 1.1, mix 2124 phenolic resin and 6101 epoxy resin in a ratio of 4:1 to make the first mixed solution.

[0079] Step 1.2, mix the first mixed solution prepared in step 1.1 with 706 water-based polyurethane resin in a ratio of 20:1 to prepare the second mixed solution.

[0080] In step 1.3, mix the acetone solution and the silane coupling agent uniformly at a ratio of 75:1 to prepare a third mixed solution.

[0081] In step 1.4, the second mixed solution and the third mixed solution are mixed and stirred evenly to prepare an epoxy resin solution.

[0082] In step 1.5, pour the alk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com