A voltage equalization control circuit with insulated gate bipolar transistors running in series

A bipolar transistor and voltage equalization control technology, which is applied in the direction of electrical components and output power conversion devices, can solve the problems of reliability differences, IGBT switching loss increase, voltage imbalance, etc., to achieve engineering realization and reliability High performance and low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

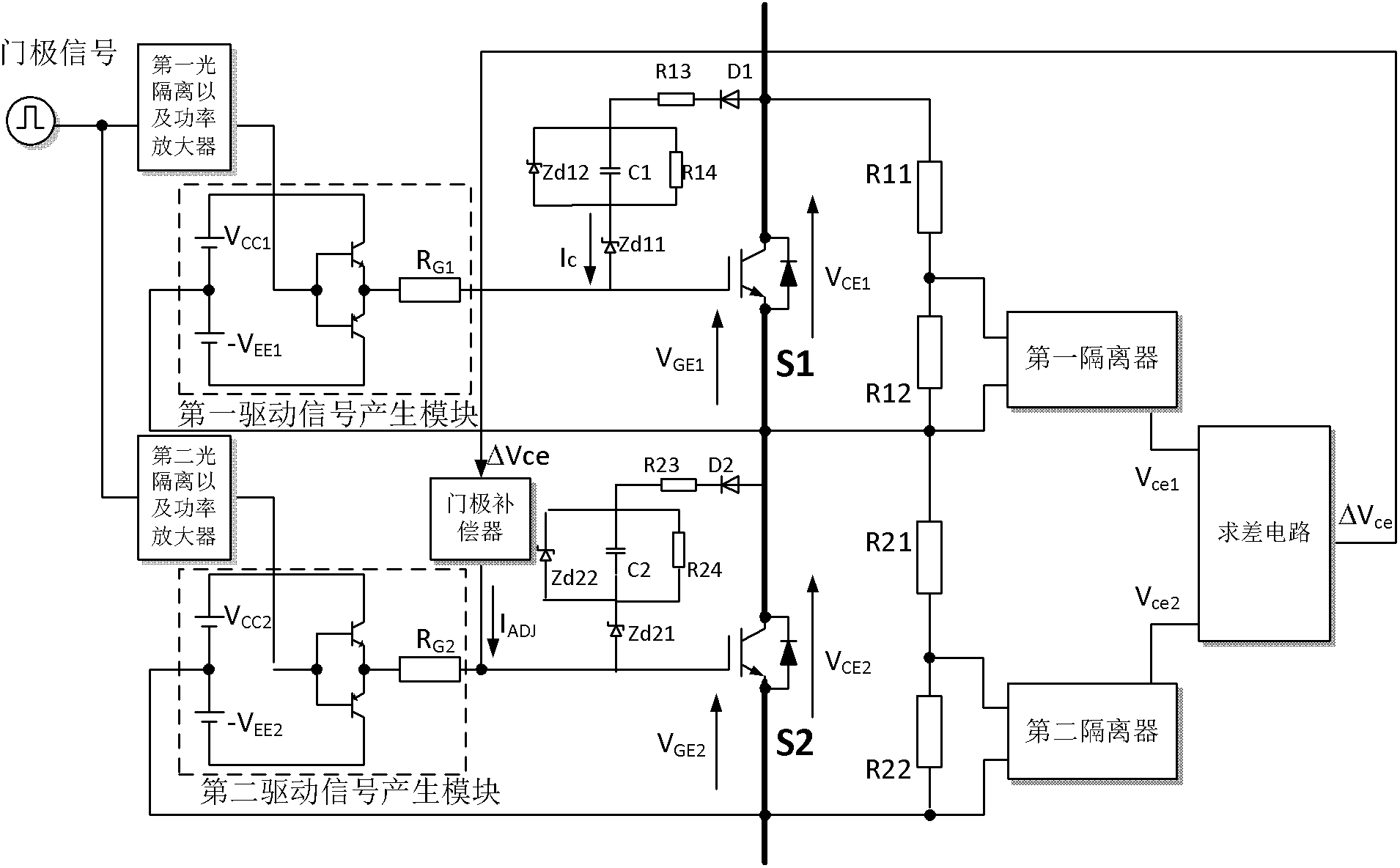

[0027] The voltage equalization control circuit of the insulated gate bipolar transistors in series operation proposed by the present invention, the circuit schematic diagram is as follows figure 1 shown, including:

[0028] The first optical isolation and power amplifier and the second optical isolation and power amplifier are respectively used to isolate and amplify the gate signal from the gate processor that controls the on-off of the insulated gate bipolar transistor to obtain an amplified gate Pole control signal;

[0029]The first driving signal generating module and the second driving signal generating module are respectively used to perform power modulation processing on the above-mentioned amplified gate control signal, and generate the first driving signal of the main IGBT transistor and the slave IGBT a second driving signal of the transistor;

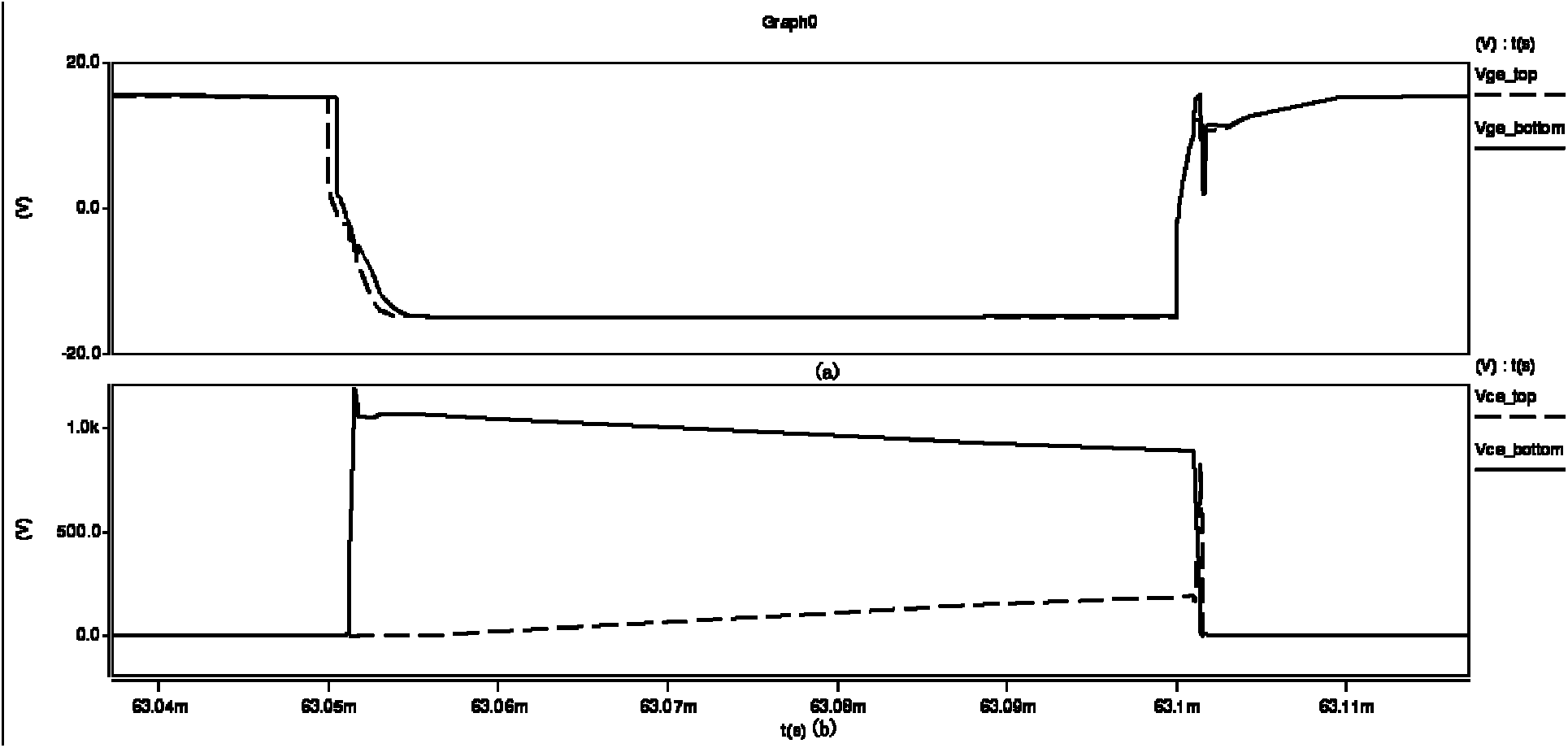

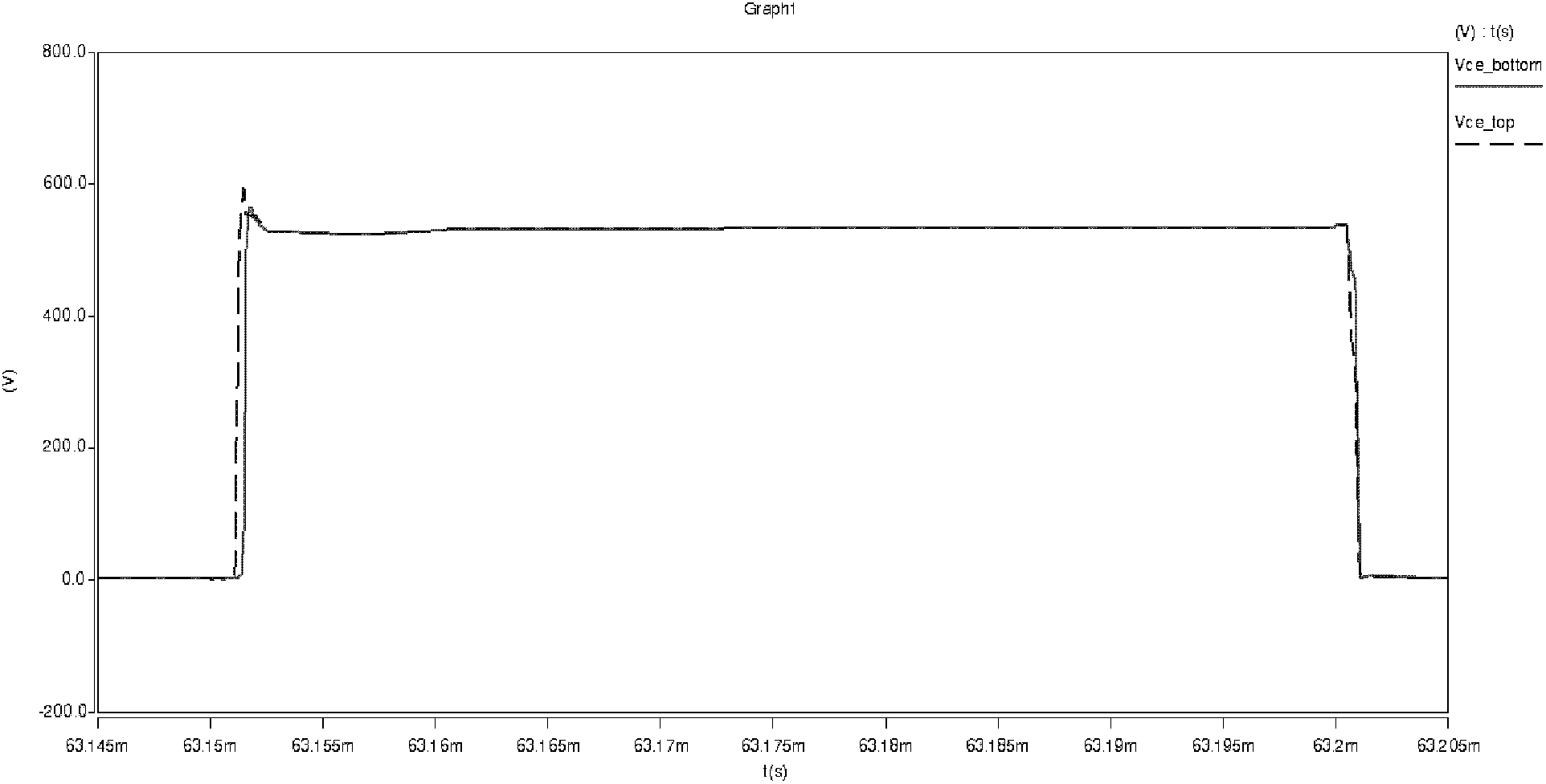

[0030] Also includes: a master-slave control circuit and an active clamp control circuit, wherein the master-slave cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com