A pre-twisted anti-skid damping spacer

A spacer and damping technology, applied in the field of spacer, can solve the problems of not being able to fix the wires, protect the wires, increase the stress, clamp the wires too tightly, etc., achieve easy control of the installation quality, and reduce stress concentration , the effect of preventing axial displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

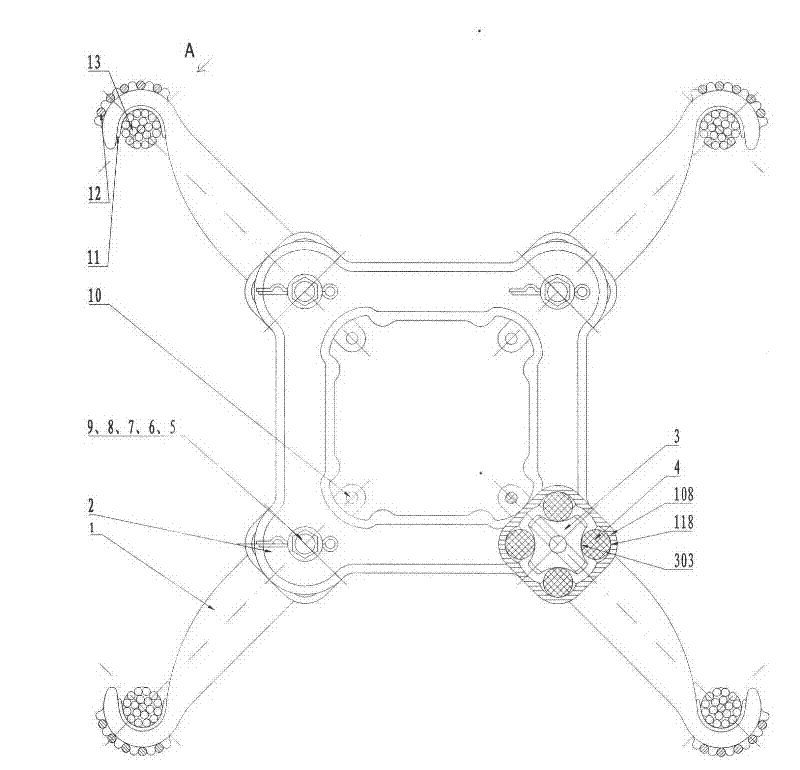

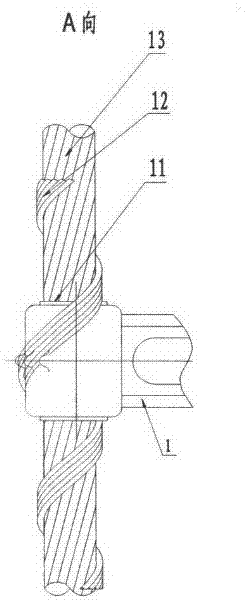

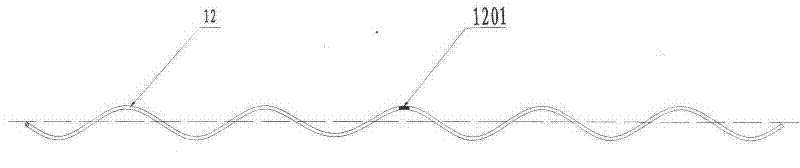

[0059] The invention is like Figure 1-23 As shown, it includes a bracket 2 and a wire clip 1. The wire clip 1 is arranged at the end corner of the bracket 2 for connecting the split wires 13, and the wire clip 1 also includes a pre-twisted wire 12; The head end of the connecting split wire 13 is in the shape of a hook 103, and the back of the hook 103 is provided with a positioning structure for positioning the pre-twisted wire 12; the tail end of the wire clip 1 and the end of the bracket The corner parts are connected by a damping limit device.

[0060] The damping limit device includes a cross hub 3, a damping rubber column 4, a hinge bolt assembly (a hinge bolt 5, a nut 6, a flat washer 7, a spring washer 8, a closing pin 9) and a limit safety pin 10;

[0061] The tail end of the wire clamp 1 is provided with a cylindrical cavity 108, the axis of the cylindrical cavity 108 is parallel to the axis of the hook 103 at the head end of the wire clamp 1, and the middle of the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com