Crown spring mounting structure with good restriction and convenient disassembly

A technology of installation structure and crown spring, which is applied in the direction of coupling device, parts of connection device, fixed/insulation contact components, etc., can solve the difficulty of disassembling the connection structure of crown spring and sleeve, the easy axial displacement of crown spring and the Circumferential displacement, axial displacement and circumferential displacement and other issues, to achieve the effect of carrying current, easy to generate heat, and large impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

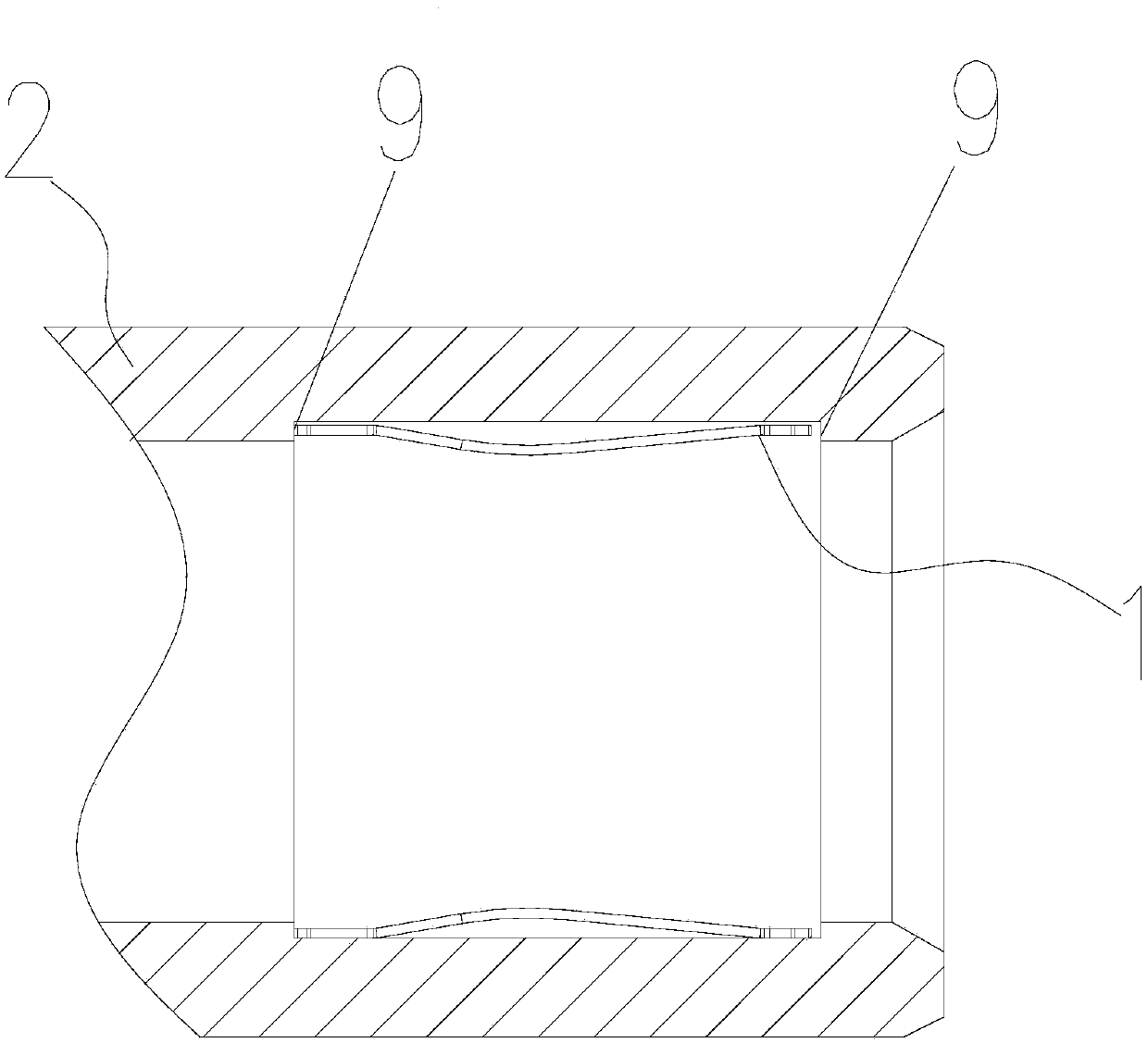

[0053] Such as Figure 4-Figure 7 The shown embodiment 1 of a crown spring installation structure with good positioning and easy disassembly of the present invention includes a crown spring 1 and a sleeve 2 sleeved on the crown spring 1, and the crown spring 1 is close to both ends. A plurality of elastic flaps 3 are evenly distributed on the outer circular surface in the circumferential direction. The elastic flaps 3 are the plate surfaces of the crown spring 1 that are turned outward. The folding plates 3 are arranged in the through holes 4 in one-to-one correspondence; the folding directions of the elastic folding plates 3 at both ends of the crown spring 1 are set in opposite directions, and the free ends of the elastic folding plates 3 are all against the holes of the through holes 4 on the wall.

[0054] When installing, press the elastic flap 3 at one end of the crown spring 1, so that the crown spring 1 is inserted into the sleeve 2, and the crown spring 1 is set in t...

Embodiment 2

[0062] Such as Figure 4 , 5 , 6, 8 and 9 show a second embodiment of a crown spring installation structure with good position-limiting and convenient disassembly of the present invention. The difference between this embodiment and the first embodiment is that the inner sleeve 2 The circular surface is provided with a first protrusion 6 in the circumferential direction, and the elastic expansion section of the reed of the crown spring 1 fits on the first protrusion 6 when it is in a tension limit state.

[0063] The elastic expansion section is a concave radial elastic expansion and contraction part in the middle of the reed of the crown spring 1 . After the pin 8 is inserted, in this embodiment, the reed of the crown spring 1 is under pressure, so that the reed can be directly attached to the first protrusion 6 of the sleeve 2, which shortens the transmission path of the energized current and reduces Volume resistance, reduce heat generation, increase current carrying capac...

Embodiment 3

[0070] Such as Figure 4 , 5, 6, 10 and 11 show a third embodiment of a crown spring installation structure with good position limiting and easy disassembly of the present invention. The difference between this embodiment and embodiment 1 is that each crown spring 1 The outer surface of the reed is provided with a second protrusion 7 in the shape of a boss. When the elastic relaxation section of the reed of the crown spring 1 is in the tension limit state, each second protrusion 7 is attached to the sleeve 2 on the inner wall.

[0071] The elastic expansion section is a concave radial elastic expansion and contraction part in the middle of the reed of the crown spring 1 . After the pin 8 is inserted, the second protrusion 7 on the reed of this embodiment can be directly attached to the inner wall of the sleeve 2 when the reed of the crown spring 1 is under pressure, shortening the transmission path of the energized current , Reduce volume resistance, reduce heat generation,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com