An ultrasonic heat meter base tube

An ultrasonic and heat meter technology, applied in the field of ultrasonic heat meter base pipes, can solve the problems of the angle offset of the reflector, which cannot be used to collect signals, large pressure loss, blockage, etc., and achieves accurate measurement, stable signal, and small fluid resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

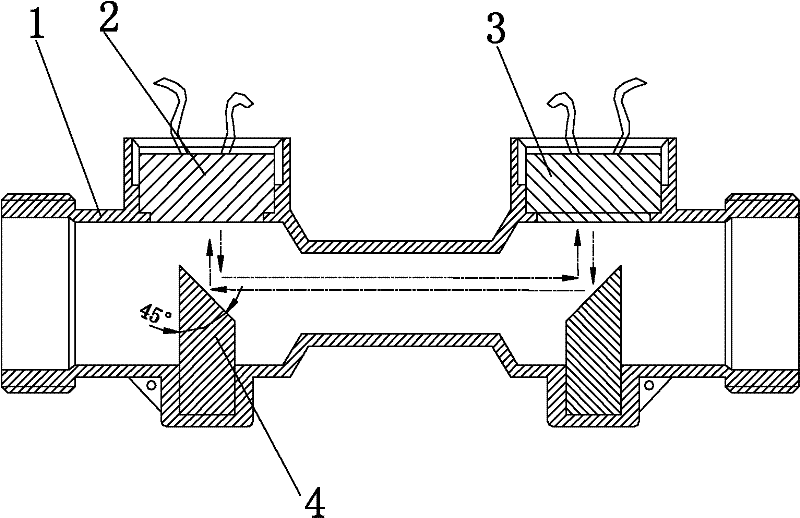

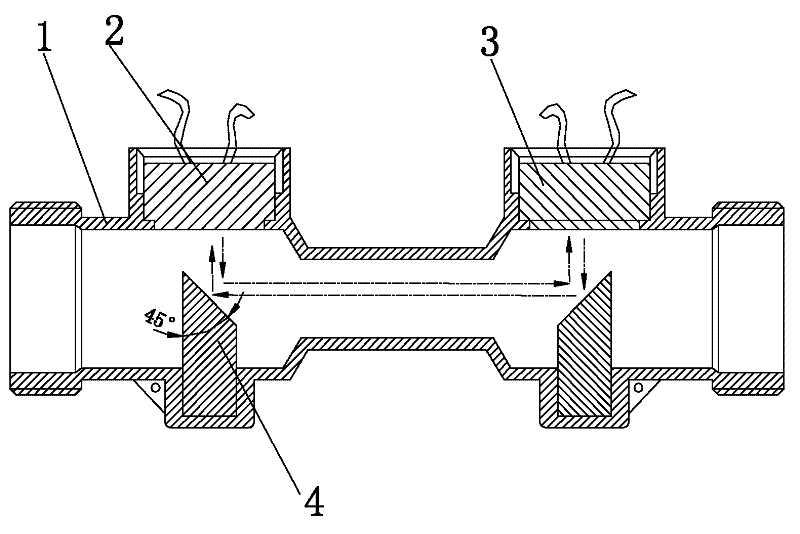

[0009] A kind of ultrasonic heat meter substrate tube of the present invention, as figure 1 As shown, it includes a tube body 1, a downstream transducer 2 attached to the tube body 1, and a countercurrent transducer 3 adapted to the downstream transducer 2. The tube body 1 is provided with a reflection block to make the downstream The ultrasonic waves emitted by the transducer can be received by the reverse flow transducer. The reflection block 4 is two metal cylinders, and the two metal cylinders are fixed on the pipe wall in the pipe body 1. In this embodiment, the inner wall of the pipe body 1 An outwardly protruding concave groove is provided, and the bottom of the reflection block 4 is embedded in the concave groove to be fixed. The upper end of the cylinder is provided with a reflective slope, the reflective slope is at an angle of 45 degrees to the cylinder, and the reflective surfaces of the two reflective blocks face each other, so that the ultrasonic wave emitted by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com