A control valve for a hydraulic wellhead safety valve control system

A control system and safety valve technology, applied in wellbore/well valve devices, wellbore/well components, earth-moving drilling, etc., can solve the problems of oil and gas well production stagnation, affecting work efficiency, low safety performance, etc. The effect of reducing the requirements of machining accuracy, improving the stability of use, and avoiding the influence of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

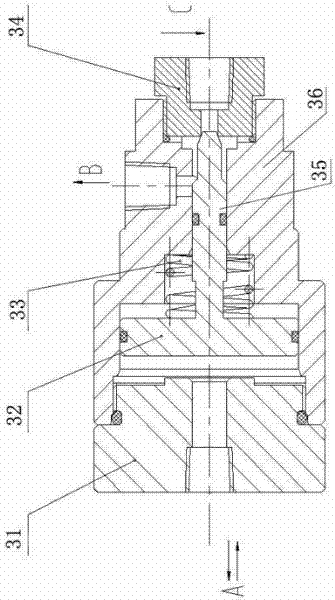

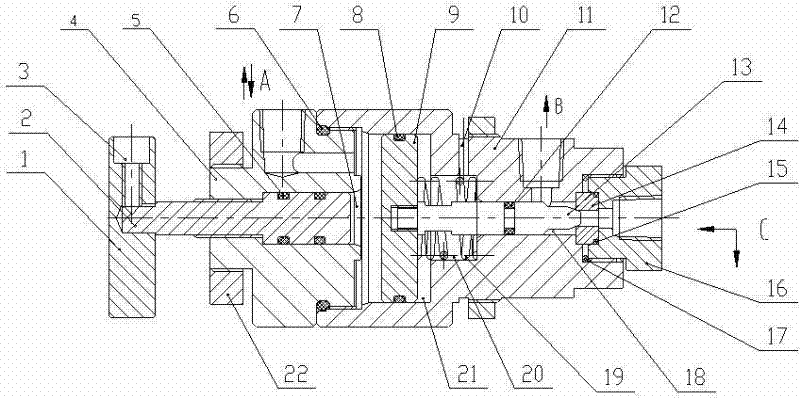

[0020] Such as figure 2 The control valve for the hydraulic wellhead safety valve control system shown includes a valve body 11, a valve hole 18 located in the center of the valve body 11, a valve core 13 located in the valve hole 18, and a front valve connected to one end of the valve body 11 by threads. Bonnet 16, the rear bonnet 4 that is threadedly connected to the other end of valve body 11; The valve core 13 and the valve hole 18 intermittent fit are provided with the fourth sealing ring 12, and the front bonnet 16 and the valve body 11 joint are provided with the first Five sealing rings 17, the second sealing ring 6 is provided at the connection between the rear valve cover 4 and the valve body 11; the inner cavity liquid cylinder 21 and the inner cavity liquid cylinder 21 are successively arranged in the valve body 11 at the end connected with the rear valve cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com