Fully enclosed ground heating runway pool microalgae breeding system

The technology of a breeding system and a runway pond is applied in the field of a fully enclosed ground-warming microalgae breeding system, which can solve the problems of low utilization rate of heat energy, high cost of construction, maintenance and management, unfavorable large-scale industrial production, etc. Heat dissipation and moisture evaporation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

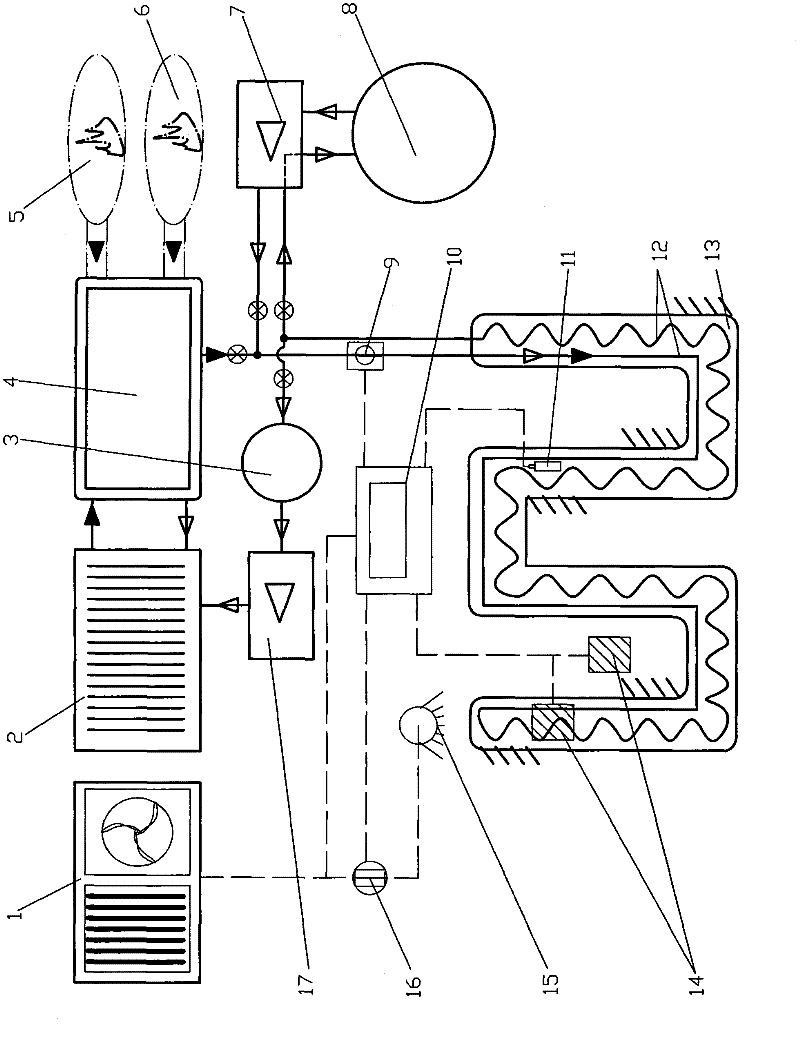

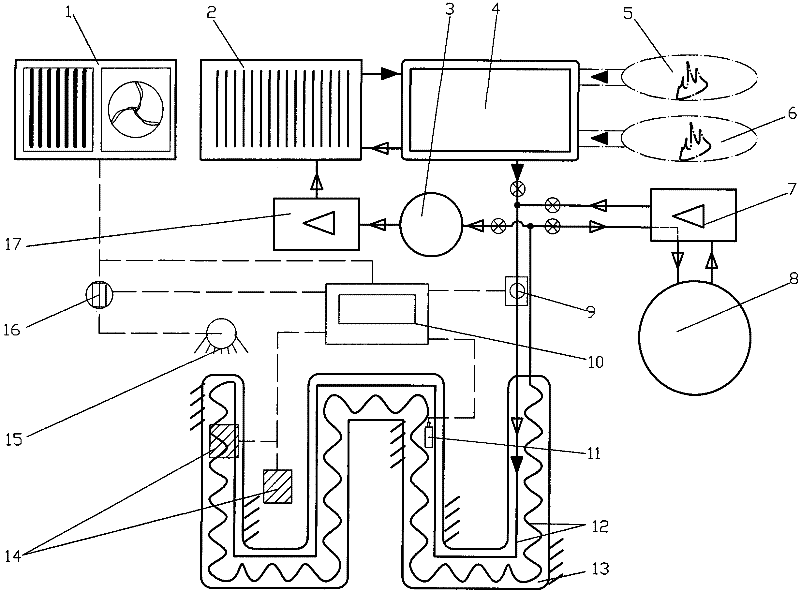

[0010] As shown in the accompanying drawings, in the microalgae culture system disclosed by the present invention, the fully enclosed floor heating track pool microalgae cultivation adopts a fully enclosed floor heating track pool 13, which is constructed below the ground, with a depth of 0.5 meters, a width of two meters, and a total length of 120 meters, reinforced with cement, and 12 heat exchange pipes are laid on the bottom of the pool. The stainless steel water exchange pipe 12 is buried 2 cm underground in the runway pool, embedded in cement, and a heat insulation layer made of 5 cm thick heat insulating material is laid under the heat exchange pipe. The water inlet and the water outlet of the heat exchange pipe are respectively connected to the hot water device and the cold water device in parallel. The hot water device is composed of a heat preservation water tank 4, a solar heat collector 2, a first water pump 17, and an underground return pool 3 connected in series ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com