Bonded wafer with thermal stress relief structure and laser scribing process

A technology of laser scribing and thermal stress, which is applied in the field of laser scribing process and bonded wafers, and can solve the problems of limiting the application of invisible laser scribing process, complex bonded wafer scribing process, and difficulty in free-form scribing. , to achieve the effects of improved mechanical properties, high yield, and reduced scribing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

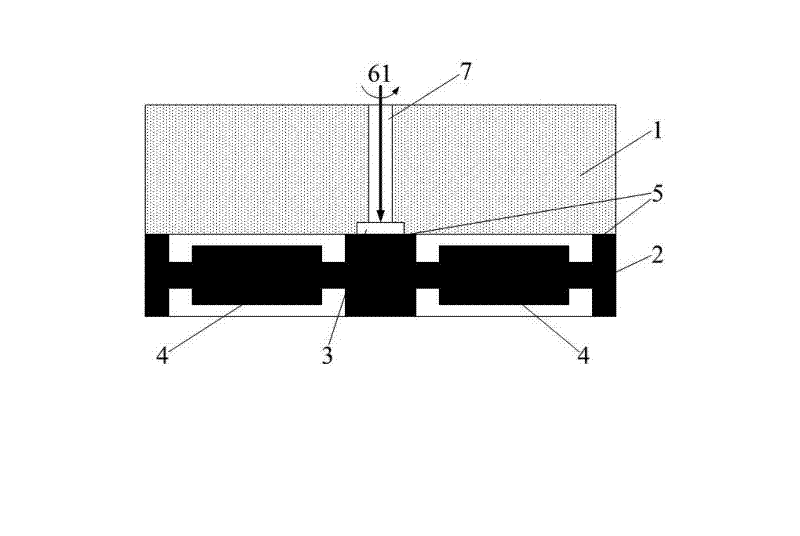

[0043] Such as figure 2 As shown, a bonded wafer with a thermal stress relief structure of the present invention is a double-layer wafer structure, including a glass wafer 1 and a silicon wafer 2 that are bonded to each other, and on the lower surface of the glass wafer 1 On the side close to the bonding contact surface 5, a thermal stress relief structure is correspondingly provided along the planned laser scribing track, and a certain number of MEMS silicon microstructures 4 are fabricated on the silicon wafer 2; in this embodiment, the thermal stress relief The structure is a thermal stress relief groove 3, which is set on the glass wafer 1 close to the bonding contact surface 5, the width of the thermal stress relief groove 3 is larger than the width of the proposed laser scribing track, and the thermal stress relief groove 3 The depth is 8 microns.

[0044] A laser scribing process such as Figure 1 ~ Figure 4 As shown, it specifically includes the following process st...

Embodiment 2

[0050] Such as Figure 6 As shown, a bonded wafer with a thermal stress relief structure of the present invention, the structure of the bonded wafer in this embodiment is basically the same as that of Embodiment 1, the difference is that the thermal stress relief groove 3 is opened in the silicon piece on wafer 2.

[0051] A laser scribing process such as Figure 5 ~ Figure 8 As shown; the laser scribing process of this embodiment is basically the same as that of Embodiment 1, only differing in the processing of the thermal stress relief structure in step (1). This embodiment utilizes a dry etching process to release the thermal stress relief groove 3 Found on silicon wafer 2, see Figure 5 ; Then, complete the scribing process through the same bonding double-layer wafer step and laser scribing step as in Example 1, see Figure 6 ~ Figure 8 .

[0052] After the dicing is completed, it can be seen from the scanning electron microscope image of the dicing cut section of the ...

Embodiment 3

[0054] Such as Figure 10 As shown, a bonded wafer with a thermal stress relief structure of the present invention is a three-layer wafer structure, which includes a top glass wafer 11, a silicon wafer 2 and a bottom that are bonded to each other from top to bottom. A certain amount of MEMS silicon microstructures 4 are made on the glass wafer 12 and the silicon wafer 2. On the top glass wafer 11, a side close to the top bonding contact surface 51 is correspondingly provided with a top heat sink along the planned laser scribing track. The stress relief groove 31, the silicon wafer 2 is located between two glass wafers, and the side of the bottom glass wafer 12 close to the bottom bonding contact surface 52 is correspondingly provided with bottom thermal stress relief along the planned laser scribing track Groove 32, the width of top thermal stress relief groove 31 and bottom thermal stress relief groove 32 is greater than the width of the proposed laser scribing track, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com