Glass medicine bottle external packaging shockproof paper holder

A medicine bottle and paper holder technology, applied in the field of medicine packaging, can solve the problems of human and animal life safety hazards, high transportation and storage costs, broken glass bottles, etc., and achieves 100% recyclability, high environmental protection value, and use and convenience. The effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

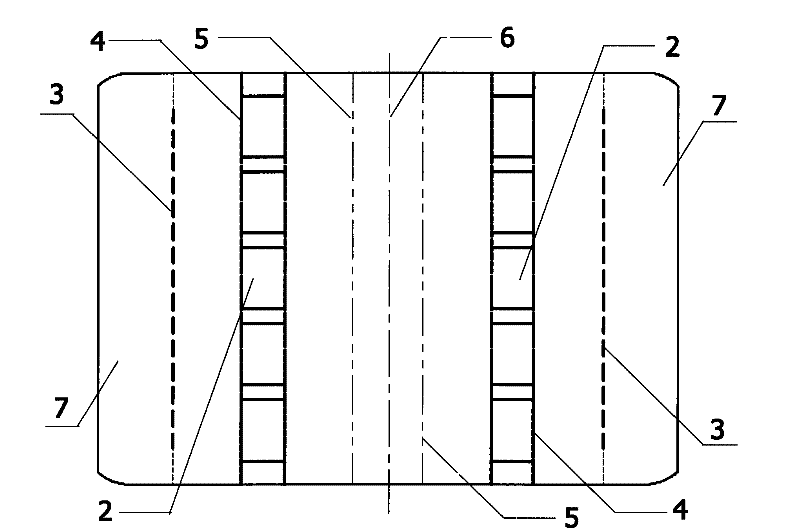

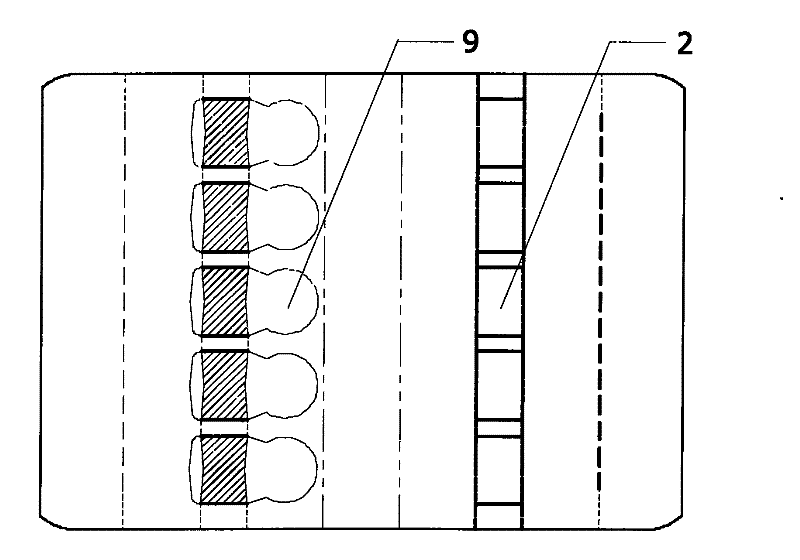

[0045] Embodiment 1: Taking standard 5mL vials of 5 bottles as an example, the shockproof paper holder for its external packaging adopts 250g / m 2 Made of coated white cardboard. Its technical scheme is: with 1: 1 as the ratio, according to the diameter, length and size of the vial (18), the tangent indentation area (2) corresponding to the bottle seat and the bottle head is first arranged, such as figure 2 As shown; symmetrically arrange all horizontal and vertical lines of dotted lines, tangent lines, and indentations. In order to facilitate the forming of the paper support, the following basic actions are required: first, according to the first indentation mold, carry out 2 / 3 deep indentation processing on the horizontal and vertical lines on the coated paper, so as to form bendable line marks; The second tangent mold performs linear half-cutting and dotted full tangent processing on the indentation of the cardboard, so as to form the crease of the paper tray; finally, acco...

Embodiment 2

[0046] Embodiment 2: Taking the common 10mL oral liquid bottle with 6 bottles as an example, the shockproof paper holder for its external packaging adopts 300g / m 2 Made of coated white cardboard. Also with a ratio of 1:1, first arrange the tangent indentation area (2) that matches the bottle base and the bottle head according to the diameter, length and size of the oral liquid bottle (19); Horizontal and vertical lines. First, use the first indentation mold to indent the horizontal and vertical lines on the coated paper at a depth of 2 / 3, so as to form bendable line marks; then use the second tangent mold to perform straight half-cutting on the indentation of the cardboard , Dotted line full tangent line processing, in order to form the crease of the paper holder; finally, according to the third full cutting and hollowing mold, the cardboard hollow shape and the full tangent line part are fully cut and hollowed out to form the bottle seat and the bottle neck. 2 / 3 arc hollow ...

Embodiment 3

[0047] Embodiment 3: Take the standard 2mL ampoules in 10 bottles as an example, the shockproof paper holder for its external packaging usually adopts 250g / m 2 Coated whiteboard production. Also still in the ratio of 1:1, according to the diameter, length and size of the ampoule bottle (20), the tangential indentation area (2) corresponding to the bottle seat and the bottle head is arranged. Due to the particularity of the ampoule (20), it is specially set according to the length of the bottle: the length of the bottle seat is less than 2 / 3 of the length of the bottle head, and all horizontal and vertical lines of dotted lines, tangent lines, and indentations are arranged asymmetrically to ensure that all The tongue area mentioned above has a certain width, leaving a certain space for the suction head of the device. First, use the first indentation mold to indent the horizontal and vertical lines on the coated paper at a depth of 2 / 3, so as to form bendable line marks; then u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com