Chopping block type comb-shaped shear crushing device

A cutting board and comb-shaped technology, which is applied in the field of chopping board-type comb-shaped cutting edge crushing device, can solve the problems of unstable support and easy material blocking, and achieve the effects of prolonging service life, easy manufacturing, and improving crushing operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

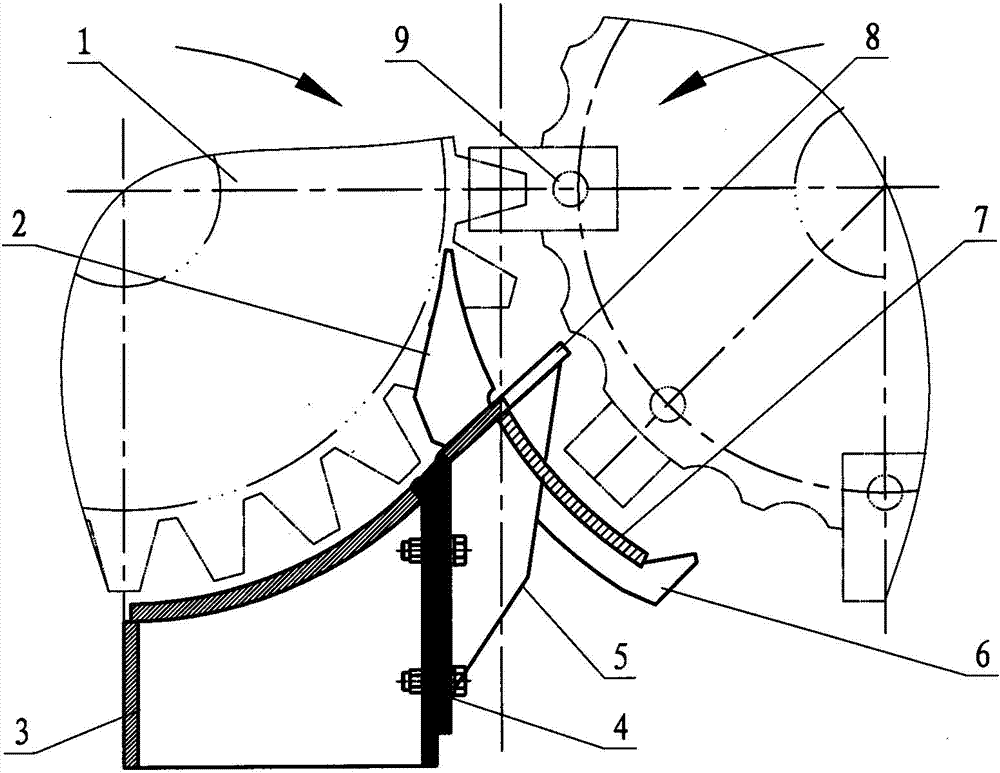

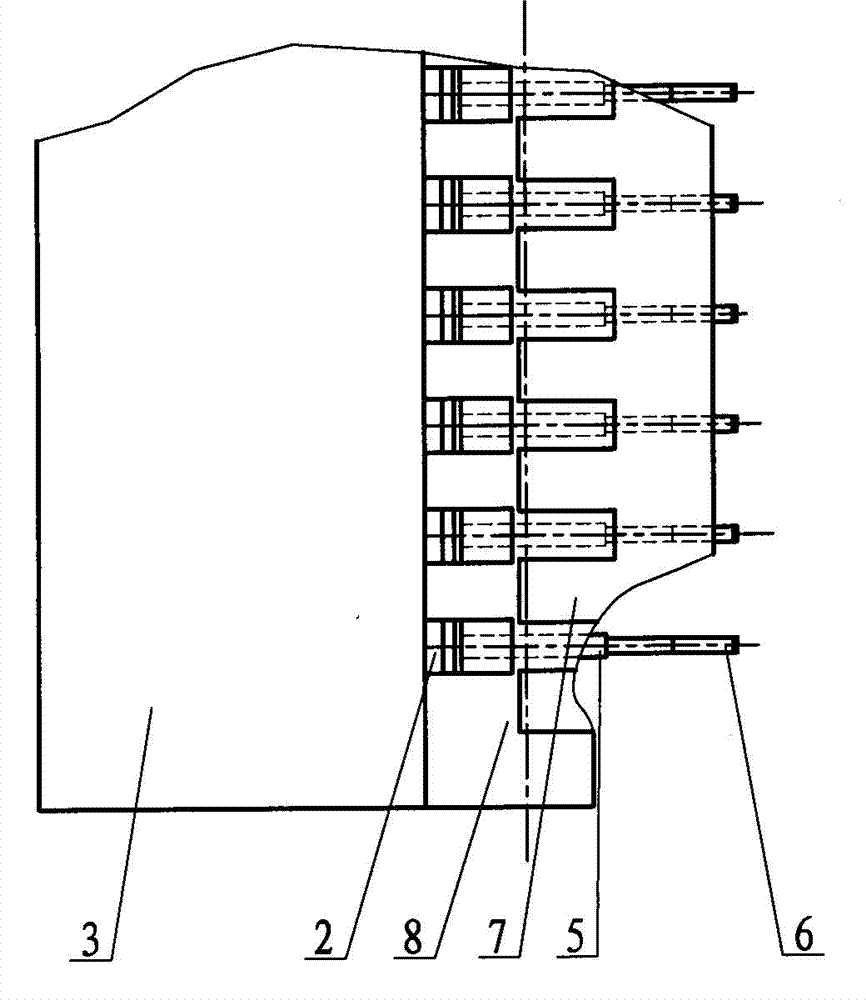

[0018] according to Figure 1~4 The specific structure of the present invention will be described in detail. This anvil-type comb-shaped cutting blade crushing device cancels the original cutting sieve plate of the existing toothed roller crusher, which is supported by a single plate and fixed on the material guide plate. The support base 3 that replaces the original support single plate under the first toothed roller rotor 1, the rib assembly 5 assembled on the stable support base 3 by fasteners, and the comb-toothed cutting board fixed on the upper surface of the rib assembly 5 8 and the shearing comb teeth 2 of the original guide cutting vertical plate, the material guide arc plate 7 and the shearing edge end teeth 6 positioned under the second gear roller rotor 9, etc. pieces. Among them, the supporting seat 3 whose top is an arc-shaped material guide surface, the rib plate assembly 5 assembled on the supporting seat 3, the comb-tooth blade cutting board 8 and the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com