Silage harvester

A harvester and green feed technology, applied in the field of harvesters, can solve the problems of affecting work efficiency, unreasonable center of gravity, poor stability, etc., and achieve the effect of improving the convenience of use, the overall center of gravity is reasonable, and the cutting is sufficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

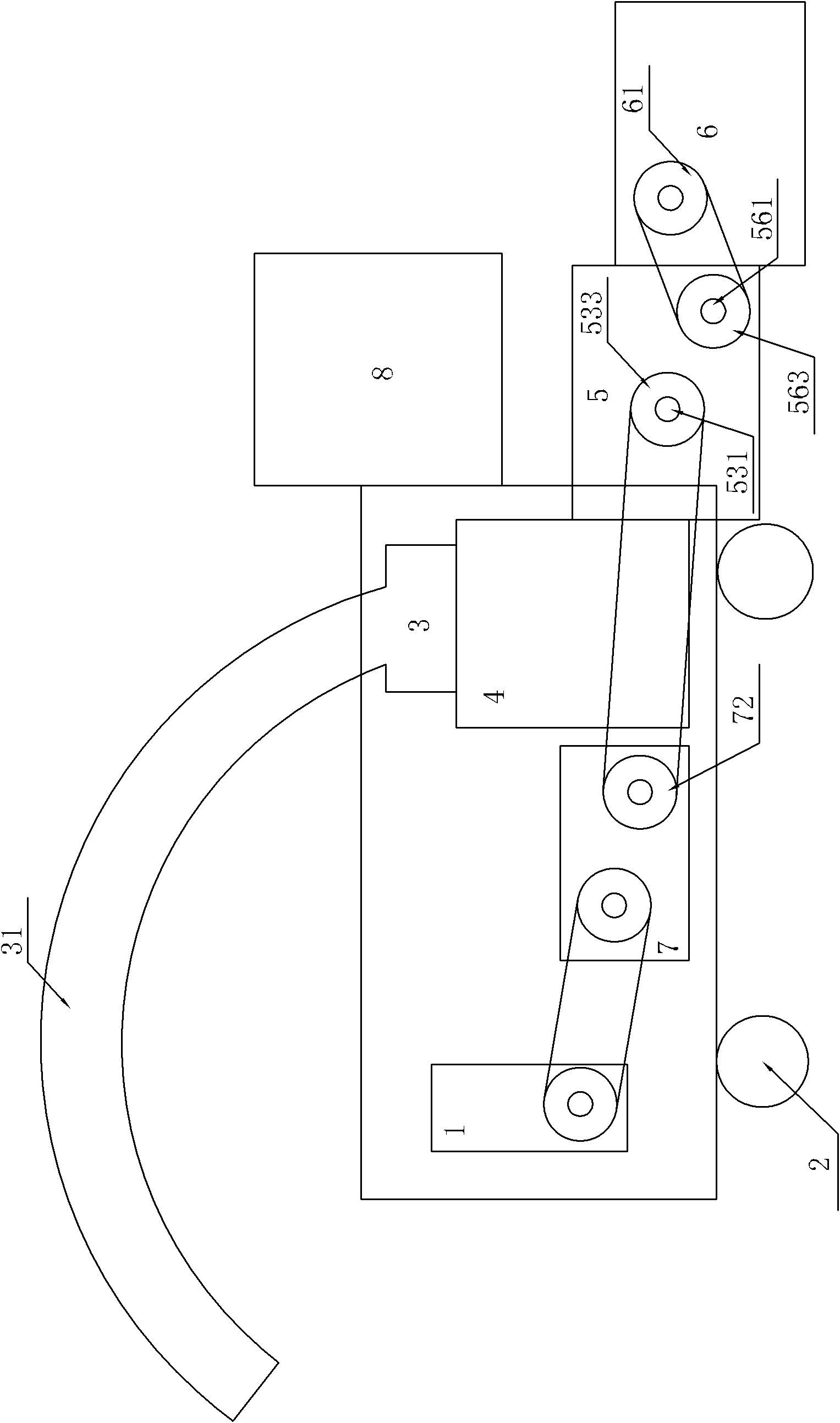

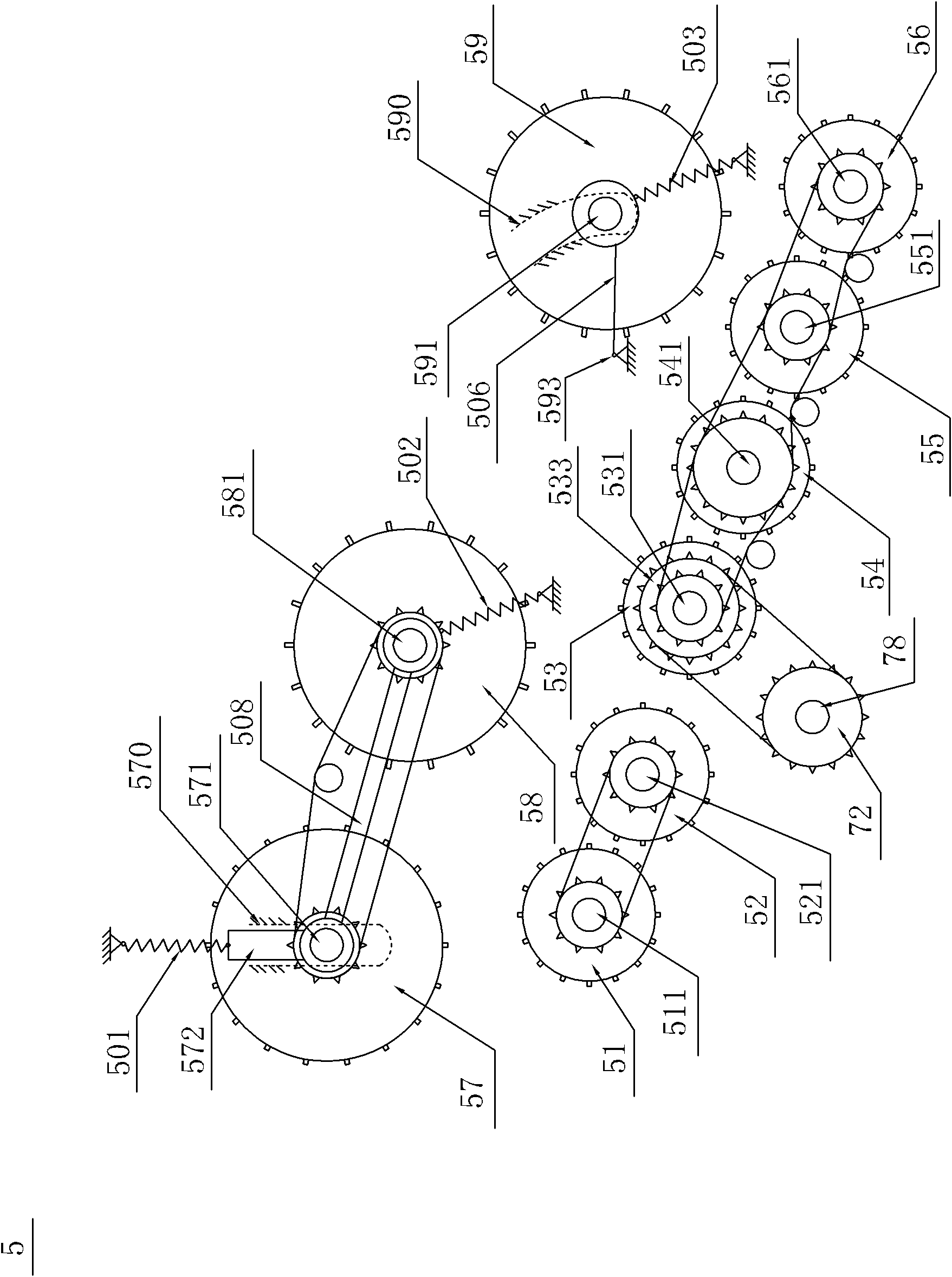

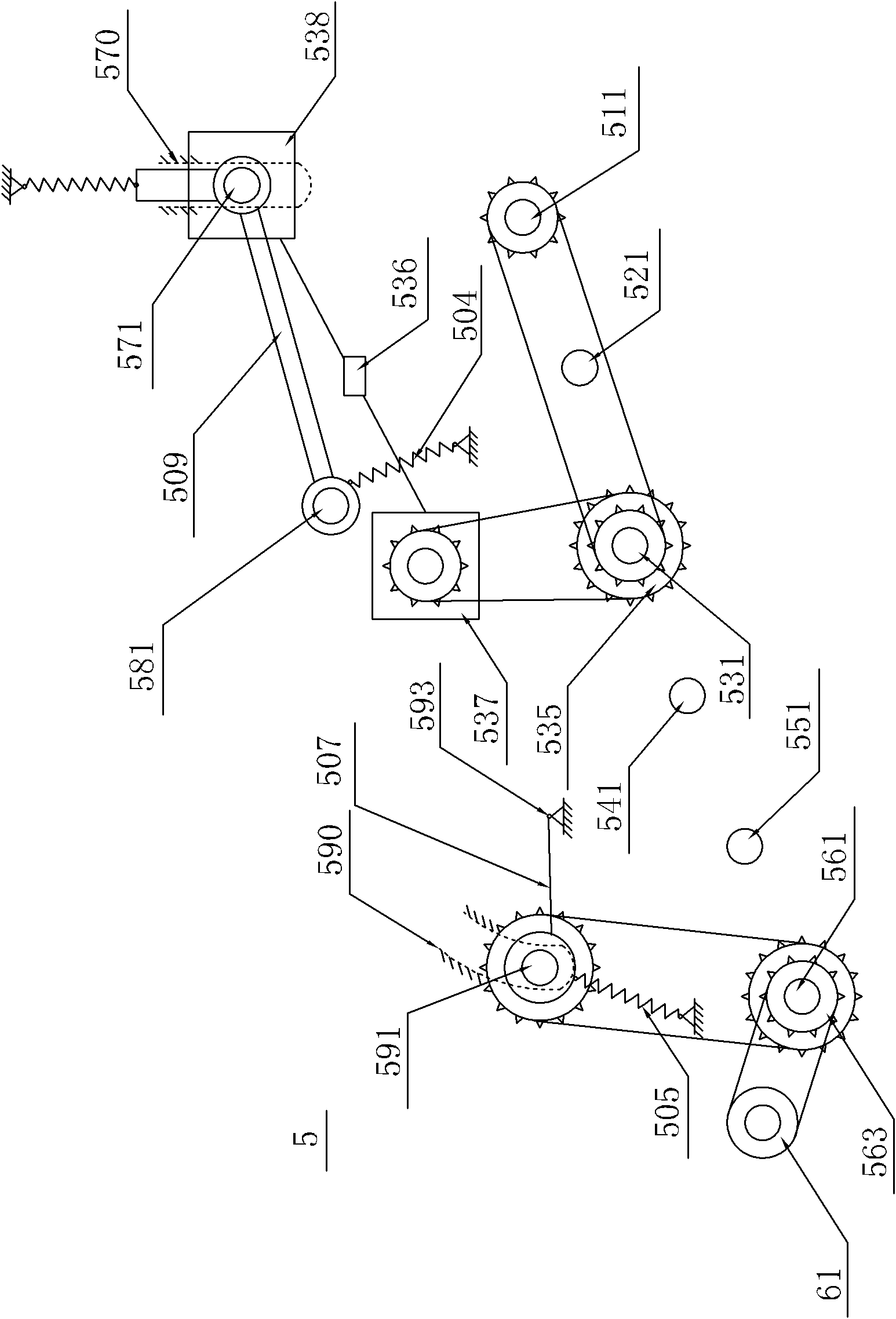

[0037] Such as figure 1 As shown, the green forage harvester of the present invention includes an engine 1, a traveling device 2, a discharge device 3, a crushing device 4, a feeding device 5, a cutting table 6, and a regurgitation mechanism 7.

[0038] Wherein, the engine 1 is arranged on the frame; the traveling device 2 is also arranged on the frame, and is connected with the engine 1 through a walking transmission mechanism to obtain power to make the frame walk; in addition, the driving device 8 is arranged on the frame, Drive to control the movement of the rack. Engine 1, running gear 2 and driver's platform 8 are common vehicle structures among the present invention, do not repeat them here.

[0039] Cutting table 6 is located at the frame front end, and it comprises several cutting disks that are rotatably arranged on the frame, and is connected with described engine through a cutting transmission mechanism to obtain power; When the harvester walks, crops such as cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com