Soft magnetic alloy thin strip, manufacturing method thereof, and magnetic component having soft magnetic alloy thin strip

A soft magnetic alloy, thin strip technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of higher insulation, lower saturation magnetic flux density, too thick oxide film, etc., to achieve excellent insulation, Effects of high saturation magnetic flux density and low core loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] The alloy melt with the composition shown in Table 1 was rapidly cooled in the atmosphere by a single roll method, and the temperature when it was peeled off from the roll surface was changed to obtain fine crystal nuclei with an average particle size of 30 nm or less in the amorphous phase at a density of 2 A thin ribbon of primary microcrystalline alloy with a width of 5 mm and a thickness of 16 to 25 μm with a dispersed structure of ~25% volume fraction. The peeling temperature of the primary microcrystalline alloy ribbon was measured by the following method.

[0101] The initial microcrystalline alloy strip was placed in a furnace with an oxygen concentration of 10% in a nitrogen atmosphere, the temperature was raised at an average of 120°C / min, and the nanocrystallization heat treatment was carried out under the conditions of maintaining the maximum temperature of 450°C for 5 minutes . The average particle size and volume fraction of the fine crystal grains in the...

Embodiment 2

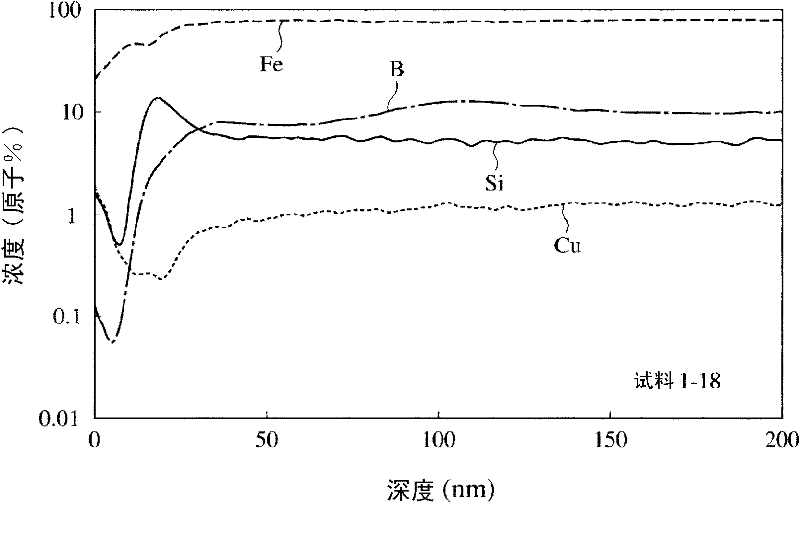

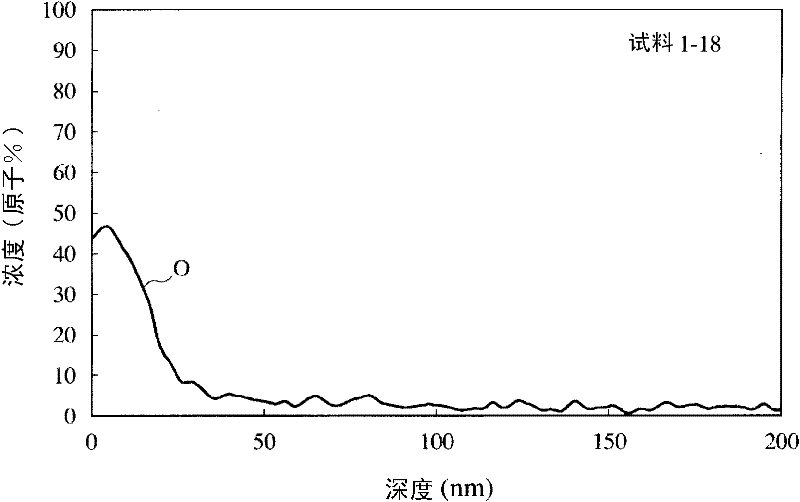

[0145] Except that the peeling temperature was 300°C, the method was the same as in Example 1, and Fe bal. Ni 1 Cu 1 Nb 1 Si 4 B 12 The alloy melt (sample 3-1) has the same composition (Fe bal. Cu 1 Nb 1 Si 4 B 12 ) alloy melts (sample 3-2), soft magnetic alloy ribbons having a structure in which fine crystal grains with an average particle diameter of 60 nm or less are dispersed in an amorphous phase at a volume fraction of 50% or more were produced. The concentration distributions of Fe, Ni, B, Si, Cu, Nb and O from the free surface to the inside of each ribbon were measured by GDOES. The measurement results of sample 3-1 are shown in FIG. 5 , and the measurement results of sample 3-2 are shown in FIG. 6 . The origin in FIGS. 5 and 6 corresponds to the surface of the sample.

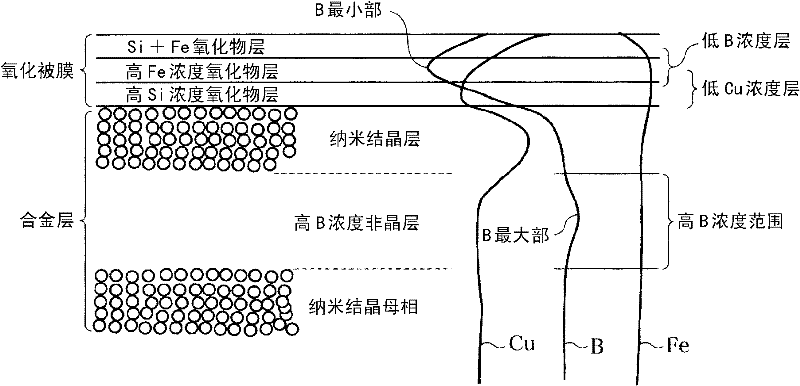

[0146] In Sample 3-1, the boundary between the oxide film and the nanocrystalline layer was around 40 nm, and a high B concentration amorphous layer with the highest B concentration existed ...

Embodiment 3

[0148] Except that the exfoliation temperature was 300° C., by the same method as in Example 1, fine crystal grains having an average grain size of 60 nm or less in the amorphous phase were produced from the alloy melt having the composition shown in Table 5. A soft magnetic alloy strip with a dispersed structure with a volume fraction of more than 50%. For each soft magnetic alloy ribbon, the depth at which the concentration of B reaches the highest was measured. In addition, the core loss (P 10 / 1k ). The results are shown in Table 5.

[0149] [table 5]

[0150]

[0151] As can be seen from Table 5, the high B-concentration amorphous layer has a depth in the range of 30 to 100 nm. Furthermore, the core loss (P 10 / 1k ) can be controlled at less than 5W / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com