A method for evenly coating fluorescent powder on a spiral fluorescent lamp tube

A technology of fluorescent tubes and phosphors, which is applied in the application of luminous paints and the manufacture of tubes/lamp screens, etc. It can solve the problems of high additional cost, uneven light brightness, waste of phosphors, etc., and improve work efficiency and product quality. Ensure the brightness and uniformity of light emission and reduce the production cost of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

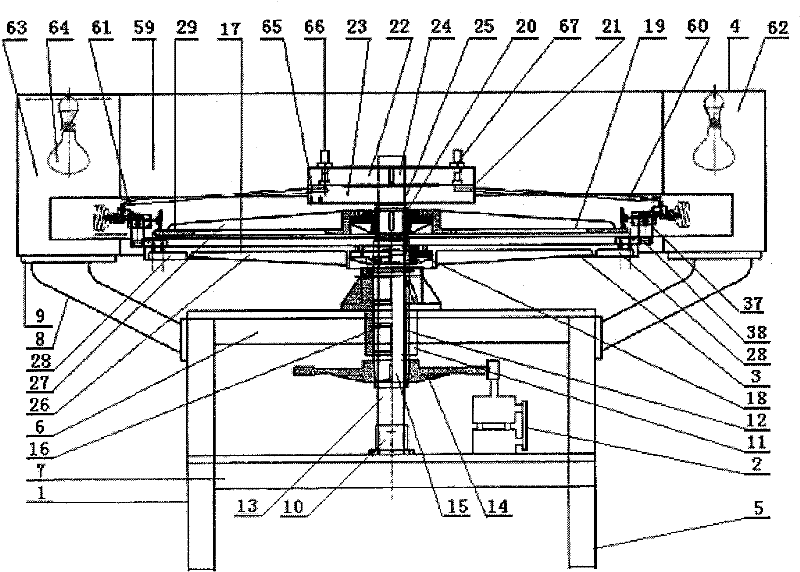

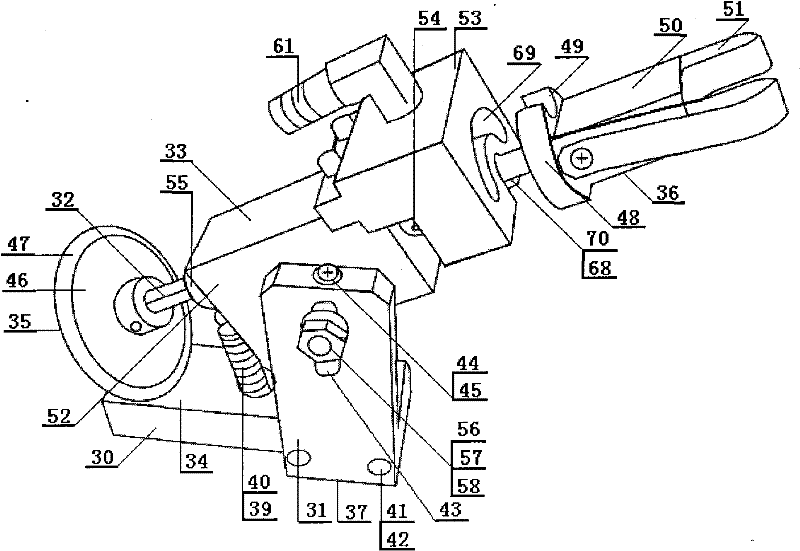

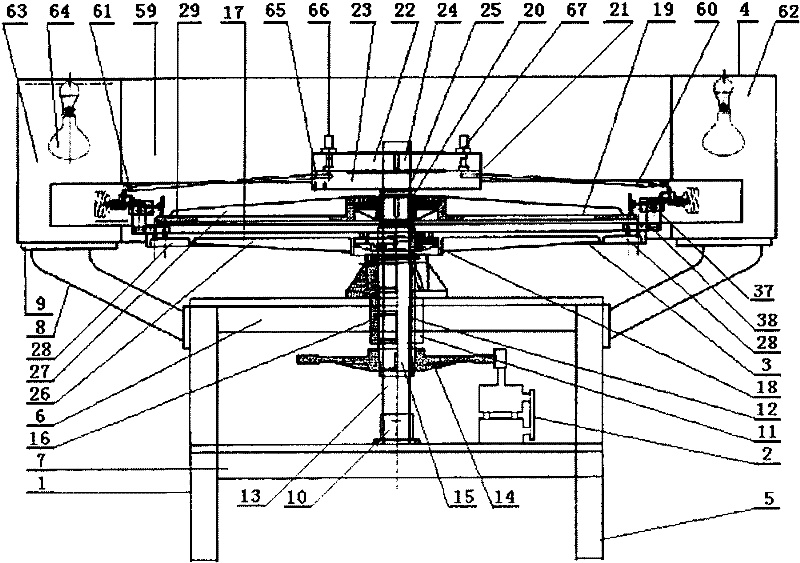

[0036] exist figure 1 and figure 2 Among them, the main body of the device for coating fluorescent powder on a spiral fluorescent tube of the present invention is mainly composed of a frame 1, a power drive mechanism 2, an action actuator 3 and a heating and drying system 4, wherein: the frame 1 is supported by support feet 5, up and down The seat frame 6 and 7 and the bracket 8 are formed, the main body of the bracket 8 is in the shape of an upwardly expanding conical ring, and its lower end is fixedly arranged on the outer side surface near the top edge of the supporting foot 5, and the upper top end is horizontal. A support plane 9 is provided, and the upper and lower support frames 6 and 7 are respectively horizontally arranged on the inner side surface of the middle and lower part of the support foot 5 and near the top end, and a spindle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com