Supercapacitor three-dimensional porous composite film and preparation method thereof

A supercapacitor, three-dimensional porous technology, applied in the direction of capacitor electrodes, capacitor parts, etc., can solve the problems of limiting high-energy and high-power supercapacitors, fast energy/power density decay, etc., to achieve good electron and ion diffusion channels, effective activity Effect of reaction area and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

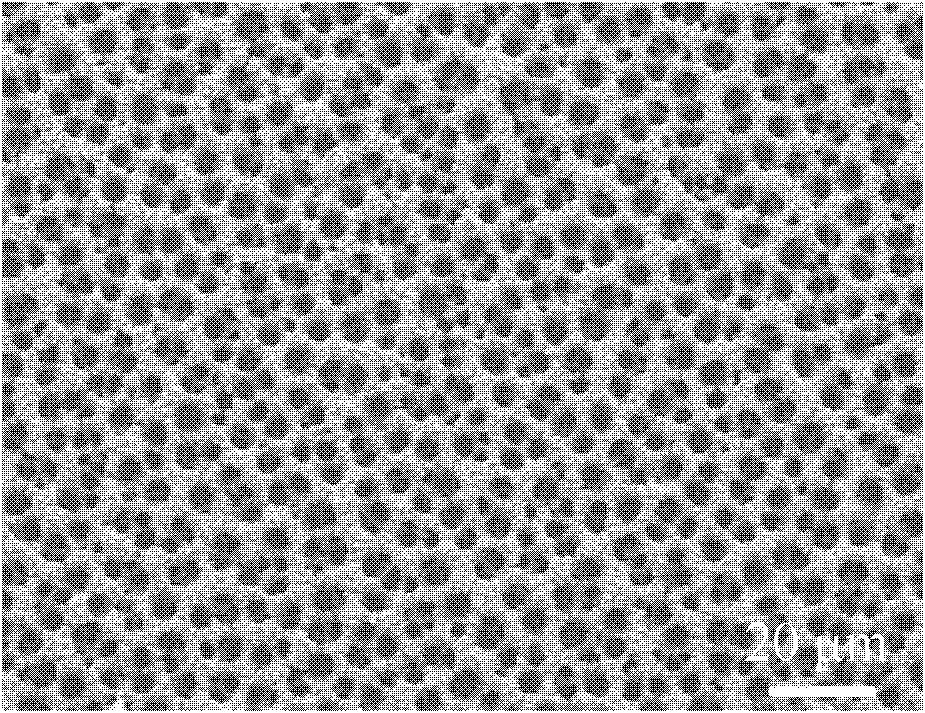

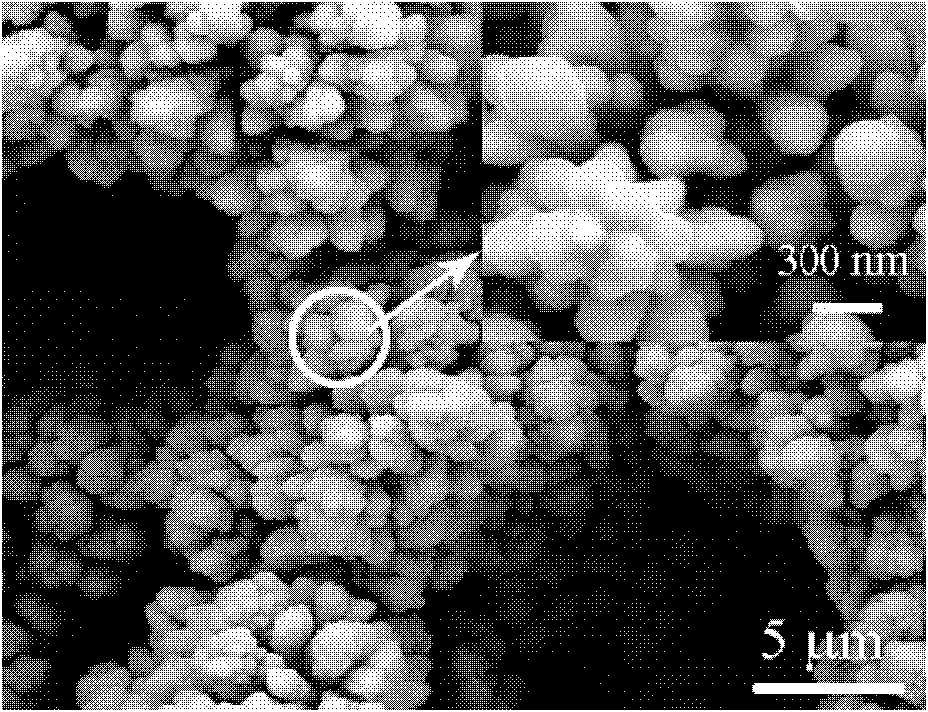

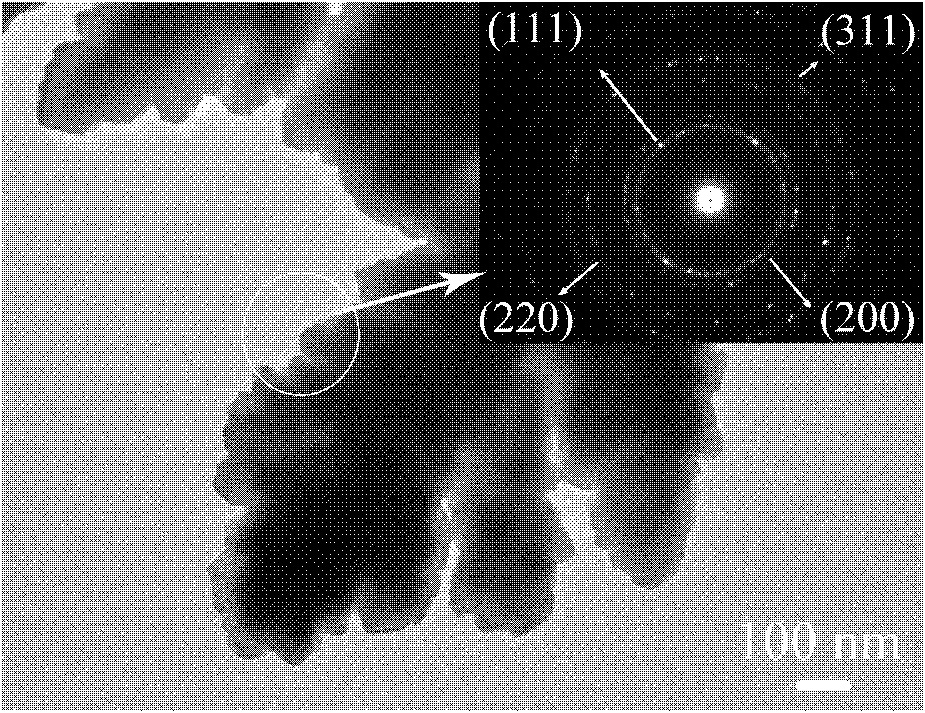

[0022] Weigh 100g of ammonium chloride and 20g of nickel chloride respectively and place them in a beaker, then add 1000mL of deionized water, and stir until completely dissolved to form a nickel-containing salt electrolyte. Then transfer the nickel-containing salt electrolyte to an electrochemical double-electrode system, wherein the nickel foil is the first working electrode, and the platinum sheet is the first auxiliary electrode. Apply a cathodic current density of 1.5A / cm on the first working electrode 2 , reacted for 60 s, and deposited on the nickel foil using the hydrogen generated by the cathode as a template to obtain a three-dimensional porous nano-nickel film. SEM, TEM and XRD analyzes were carried out on the obtained three-dimensional porous nano-nickel film, and its scanning electron microscope and local enlarged pictures are shown in figure 1 with 2 As shown, it can be seen that in the three-dimensional porous nano-nickel film, the large pores range from 6 to ...

Embodiment 2

[0025] Weigh 200g of ammonium chloride and 20g of nickel chloride respectively and place them in a beaker, then add 1000mL of deionized water, and stir until completely dissolved to form a nickel-containing salt electrolyte. Then transfer the nickel-containing salt electrolyte to an electrochemical double-electrode system, wherein the nickel foil is the first working electrode, and the platinum sheet is the first auxiliary electrode. Apply a cathodic current density of 2A / cm on the first working electrode 2 , reacting for 120s, using the hydrogen generated by the cathode as a template, depositing on the nickel foil to obtain a three-dimensional porous nano-nickel film. The three-dimensional porous nano-nickel thin film has a large pore range of 7-13 μm, a small pore range of 110-550 nm, and a film thickness of 115 μm.

[0026] Weigh 180g of cobalt nitrate and 5g of sodium nitrate and dissolve them in 1000mL of deionized water, and stir until completely dissolved to form a cob...

Embodiment 3

[0028] Weigh 300g of ammonium chloride and 20g of nickel chloride respectively and place them in a beaker, then add 1000mL of deionized water, and stir until completely dissolved to form a nickel-containing salt electrolyte. Then transfer the nickel-containing salt electrolyte to an electrochemical double-electrode system, wherein the nickel foil is the first working electrode, and the platinum sheet is the first auxiliary electrode. Apply a cathodic current density of 3A / cm on the first working electrode 2, reacting for 180s, using the hydrogen generated by the cathode as a template, depositing on the nickel foil to obtain a three-dimensional porous nano-nickel film. The three-dimensional porous nano-nickel thin film has a large pore range of 8-11 μm, a small pore range of 150-480 nm, and a film thickness of 196 μm.

[0029] Weigh 360g of cobalt nitrate and 10g of sodium nitrate and dissolve them in 1000mL of deionized water, and stir until completely dissolved to form a cob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com