Flame-retardant rubber-sheathed flexible cable for underground coal mine mobile equipment and preparation method thereof

A mobile device and flexible cable technology, which is applied in the field of power feeder-rubber sheathed flexible cable, can solve the problems of unfavorable rescue of trapped underground personnel, large amount of smoke, and reduced light transmittance of underground passages, etc. The possibility of survival, the reduction of corrosive gas, and the effect of reducing irritation and damage to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Inner sheath 3 and outer sheath 4 two-machine common head one-step extrusion method:

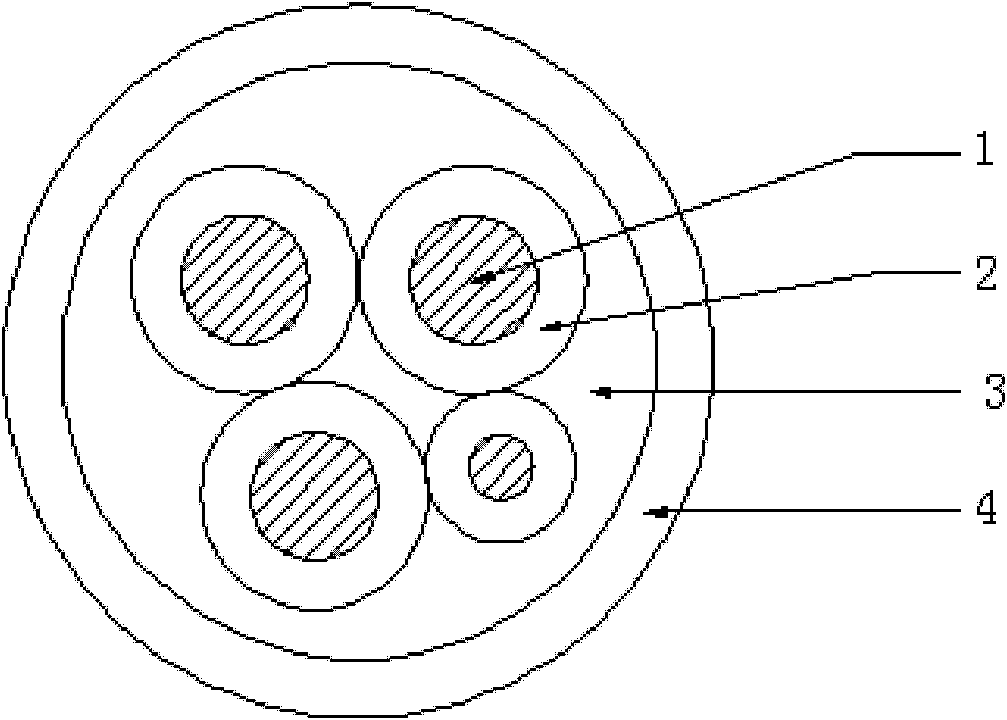

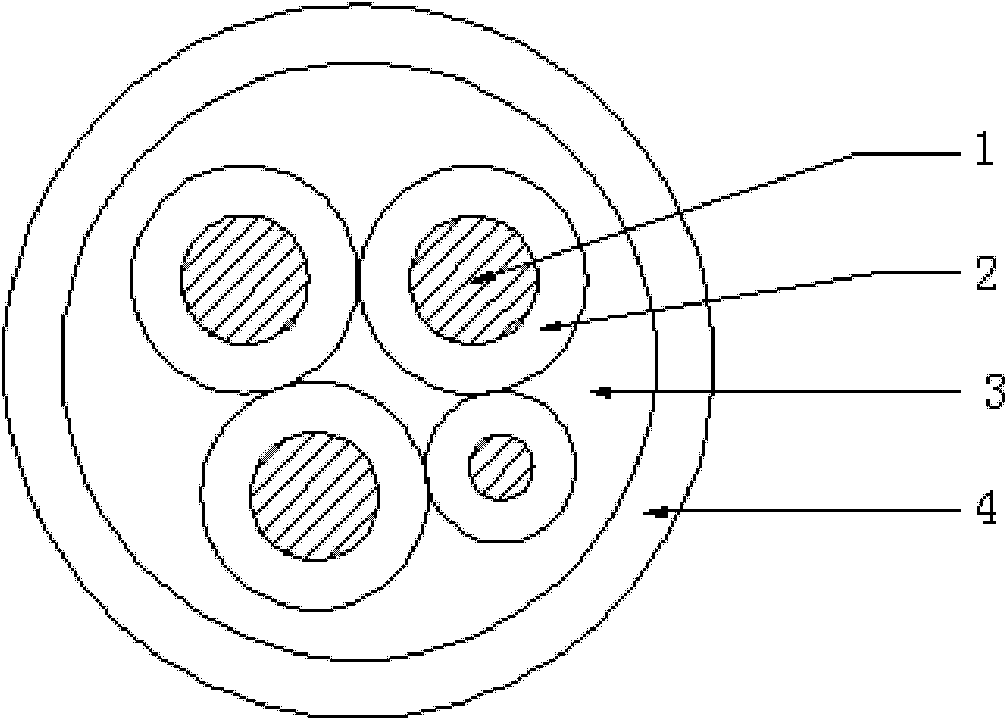

[0020] The first step is to select the fifth soft copper conductor that meets the provisions of the national standard GB / T 3956-1997 , for example, with a nominal cross-sectional area of 50mm 2 , on the extrusion vulcanization continuous production line, according to the insulation thickness specified in MT-818, the halogen-free, low-smoke, low-corrosion, flame-retardant insulating compound is tightly extruded on the selected soft copper conductor, and the vulcanization process is carried out in the vulcanization pipeline. Vulcanization, according to the vulcanization characteristics of the rubber material, the temperature of the saturated steam in the pipeline is 175~183℃, and the residence time in the pipeline is 5~8 minutes, forming figure 1 Halogen-free, low-smoke, low-corrosion, flame-retardant rubber insulating layer 2, this process is called insulation continu...

Embodiment 2

[0023] Embodiment 2, inner sheath 3 and outer sheath 4 two-machine serial connection one-step extrusion method:

[0024] The first step is to select the fifth soft copper conductor that meets the provisions of the national standard GB / T 3956-1997 , for example, with a nominal cross-sectional area of 50mm 2 , on the extrusion vulcanization continuous production line, according to the insulation thickness specified in MT-818, the halogen-free, low-smoke, low-corrosion, flame-retardant insulating compound is tightly extruded on the selected soft copper conductor, and the vulcanization process is carried out in the vulcanization pipeline. Vulcanization, according to the vulcanization characteristics of the rubber material, the temperature of the saturated steam in the pipeline is 175~183°C, and the residence time in the pipeline is 5~8 minutes, forming figure 1 Halogen-free, low-smoke, low-corrosion, flame-retardant rubber insulating layer 2, this process is called insulation ...

Embodiment 3

[0027] Embodiment 3: Inner sheath 3 and outer sheath 4 stand-alone two-step extrusion method:

[0028] The first step is to select the fifth soft copper conductor that meets the provisions of the national standard GB / T 3956-1997 , for example, with a nominal cross-sectional area of 50mm 2 , on the extrusion vulcanization continuous production line, according to the insulation thickness specified in MT-818, the halogen-free, low-smoke, low-corrosion, flame-retardant insulating compound is tightly extruded on the selected soft copper conductor, and the vulcanization process is carried out in the vulcanization pipeline. Vulcanization, according to the vulcanization characteristics of the rubber material, the temperature of the saturated steam in the pipeline is 175~183°C, and the residence time in the pipeline is 5~8 minutes, forming figure 1 Halogen-free, low-smoke, low-corrosion, flame-retardant rubber insulating layer 2, this process is called insulation continuous vulcani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com