Convex asymmetric corrugated tube heat exchanger

An asymmetric and corrugated tube technology, which is applied in the field of corrugated tube heat exchangers and convex asymmetric corrugated tube heat exchangers, can solve the problem of low comprehensive heat transfer efficiency and unsuitable gas-steam heat exchange It can improve the overall heat transfer efficiency, smooth the fluid flow, and reduce the flow dead zone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

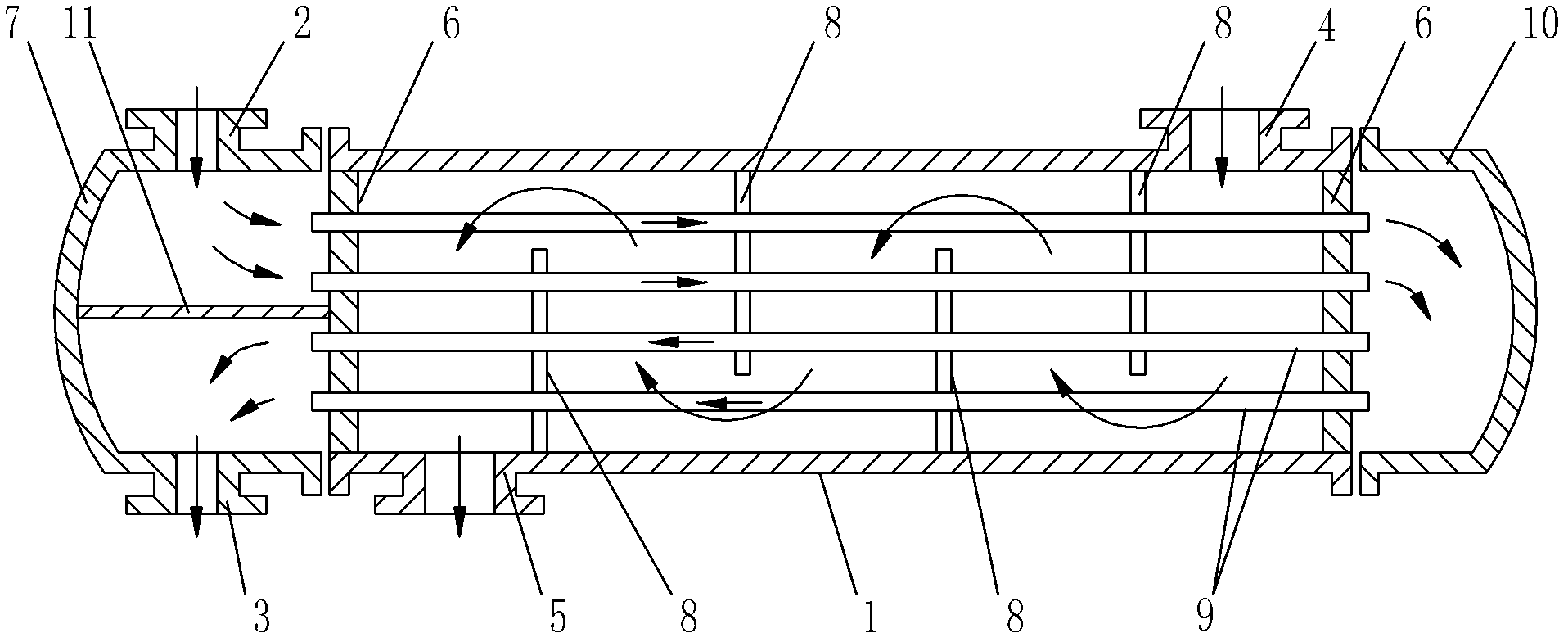

[0015] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 To illustrate this embodiment, the convex asymmetric corrugated tube heat exchanger of this embodiment includes a shell 1, a cold medium inlet pipe 2, a cold medium outlet pipe 3, a heat medium inlet pipe 4, a heat medium outlet pipe 5, two A tube plate 6, a first head 7, a second head 10, a horizontal partition 11, a plurality of baffles 8 and a plurality of heat exchange tubes 9, and a tube plate 6 is respectively installed on the inner walls of both ends of the shell 1 A first seal head 7 is installed on one end surface of the shell 1, a second seal head 10 is installed on the other end surface of the shell 1, a heat medium inlet pipe 4 is arranged on the top of the shell 1, and a heat medium inlet pipe 4 is arranged on the bottom of the shell 1. The heat medium outlet pipe 5, the first head 7 is provided with a horizontal partition 11, the top of the first head 7 is provided w...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 , figure 2 and image 3 To describe this embodiment, the convex asymmetrical corrugated pipe of this embodiment is made of carbon steel, alloy steel or stainless steel. Such setting is convenient for processing and forming, and has low cost and long service life. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

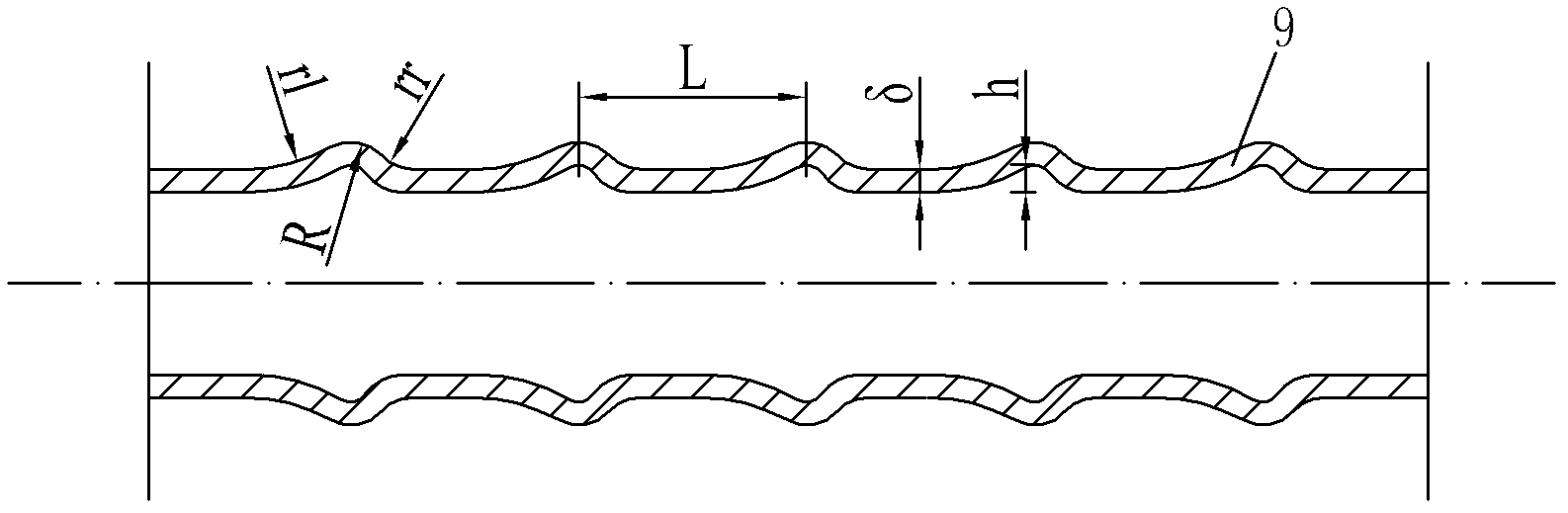

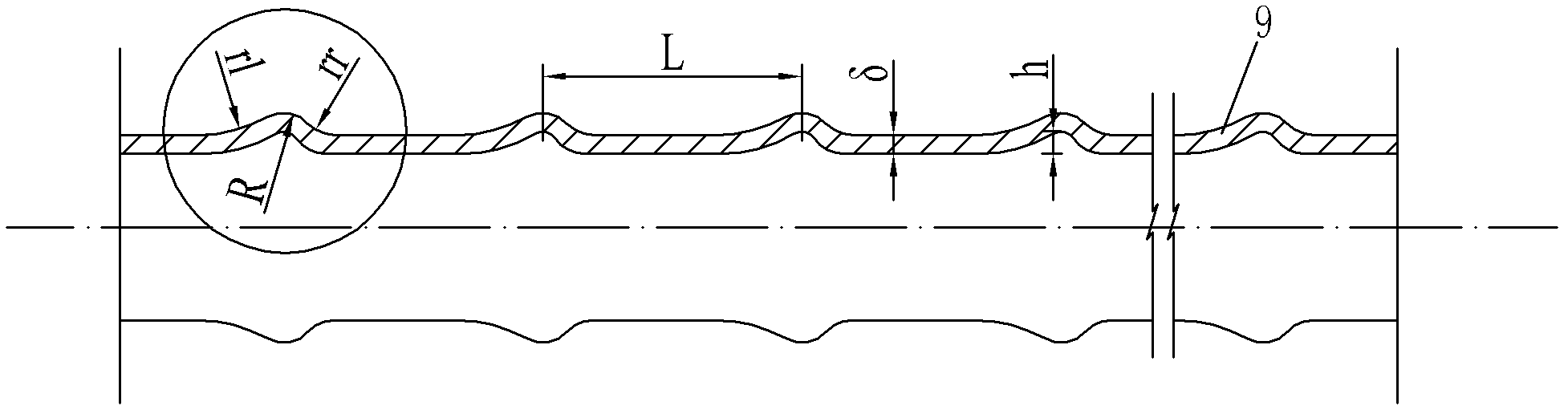

[0017] Specific implementation mode three: combination figure 2 , image 3 and Figure 4 To describe this embodiment, the outer wall of the convex asymmetric corrugated tube in this embodiment is located on the outflow side. The radius of curvature rl of the arc surface is 10mm to 30mm. This setting eliminates the flow dead zone in the rising area of the corrugated joints, and makes the fluid flow smoother and the flow resistance smaller. Compared with the corresponding symmetrical corrugated tubes, the heat transfer is almost unchanged, but the overall heat transfer efficiency is greatly improved. . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com