Plugging Method and Control System for Drilling Reservoir Fractures

A plugging method and technology for a control system, which are used in earth-moving drilling, wellbore/well components, sealing/packaging, etc., can solve the problems of increasing oil and gas production costs, multiple plugging, and loss of oil and gas seepage channels, etc. Convenience, practicality, timeliness, reasonable demand, no waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] see figure 1 : a plugging method for drilling reservoir fractures, comprising the following sequential steps:

[0037] (1). Collect geological parameters 3, drilling parameters 4, drilling fluid parameters 5 and loss parameters 6, where geological parameters 3 include porosity and fracture inclination, drilling parameters 4 include open hole diameter, drilling footage and differential pressure, drilling fluid Parameter 5 includes plastic viscosity and compressibility coefficient, and leakage parameter 6 includes leakage volume and leakage time. These parameters are applied to the following calculation model, and lost circulation (reservoir) fracture width 1 is obtained through calculation; the calculation model is as follows,

[0038] ;

[0039] In the formula: is the crack width;

[0040] is the formation porosity;

[0041] r eq is the equivalent radius of the borehole;

[0042] △ is the positive drilling pressure difference;

[0043] is the plastic vis...

Embodiment 2

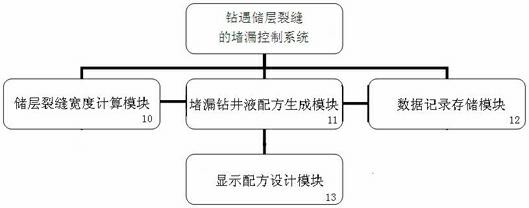

[0056] see figure 2 A plugging control system for drilling reservoir fractures, including a reservoir fracture width calculation module 10 of an interactive user interface, a plugging drilling fluid formula generation module 11, a data record storage module 12 and a display formula design module 13. in:

[0057] Reservoir fracture width calculation module 10: According to the collected geological parameters, drilling parameters, drilling fluid parameters and leakage parameter information, based on the system's calculation model comprehensive analysis and calculation to obtain the width of reservoir fractures; the aforementioned geological parameters include porosity and fracture Inclination angle, drilling parameters include open hole diameter, drilling footage and differential pressure, drilling fluid parameters include plastic viscosity and compressibility coefficient, and loss parameters include loss volume and loss time.

[0058] The above calculation model is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com