Method for preparing fibers by thermoplastic carboxymethylcellulose derivatives through electrostatic spinning

A technology of carboxymethyl cellulose and electrospinning, which is applied to artificial filaments made of cellulose derivatives, fiber treatment, filament/thread forming, etc., to achieve the effects of simple operation, environmental friendliness, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing fibers by electrostatic spinning of thermoplastic carboxymethylcellulose derivatives, comprising the following steps:

[0031] a. For thermoplastic modification of cellulose, dissolve 20 parts of sodium carboxymethyl cellulose (parts by weight, grams, the same hereinafter) in the water system, add ammonium persulfate after swelling, and add 100 parts of methyl acrylate for graft copolymerization Reaction, react at 75°C for 4 hours, precipitate and extract with 50 parts of ethanol for 8 hours, and dry to obtain thermoplastic cellulose;

[0032] b. The prepared thermoplastic cellulose is pulverized, and the powder is dissolved in tetrahydrofuran solvent to prepare a solution with a weight percentage of 3%, and then the solution is fully stirred so that it is completely dissolved, and the solution is placed in an ultrasonic wave to completely separate out the bubbles. Obtain an electrospinning solution;

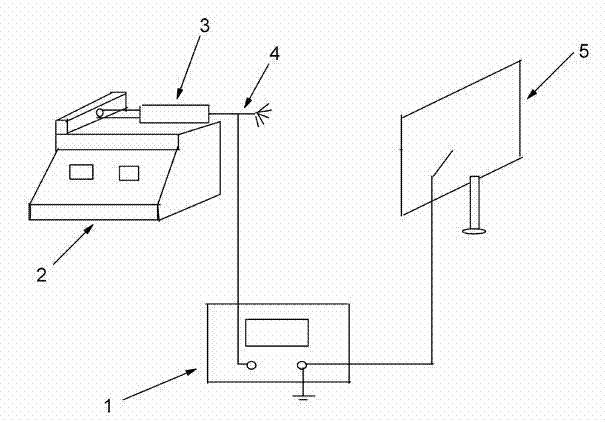

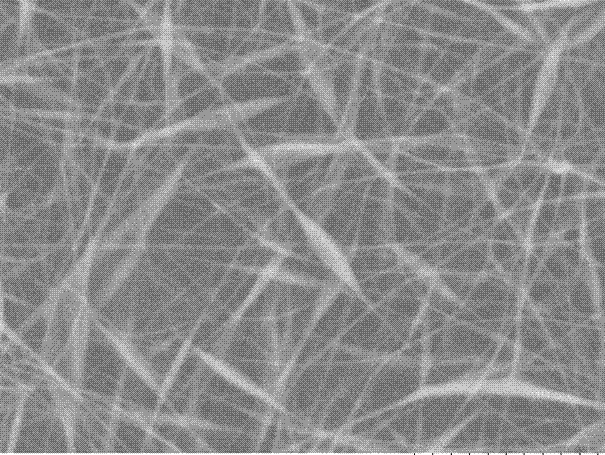

[0033] c. Extract the electrospinning soluti...

Embodiment 2

[0035] A method for preparing fibers by electrostatic spinning of thermoplastic carboxymethylcellulose derivatives, comprising the following steps:

[0036] a. For thermoplastic modification of cellulose, dissolve 20 parts of sodium carboxymethyl cellulose (parts by weight, grams, the same hereinafter) in the water system, add ammonium persulfate after swelling, and add 100 parts of methyl acrylate for graft copolymerization Reaction, react at 75°C for 4 hours, precipitate and extract with 50 parts of ethanol for 8 hours, and dry to obtain thermoplastic cellulose;

[0037]b. The prepared thermoplastic cellulose is pulverized, and the powder is dissolved in tetrahydrofuran solvent to prepare a solution of 4% by weight, then the solution is fully stirred so that it is completely dissolved, and the solution is placed in an ultrasonic wave to completely separate out the bubbles. Obtain an electrospinning solution;

[0038] c. Extract the electrospinning solution prepared in step ...

Embodiment 3

[0040] A method for preparing fibers by electrostatic spinning of thermoplastic carboxymethylcellulose derivatives, comprising the following steps:

[0041] a. For thermoplastic modification of cellulose, dissolve 20 parts of sodium carboxymethyl cellulose (parts by weight, grams, the same hereinafter) in the water system, add ammonium persulfate after swelling, and add 100 parts of methyl acrylate for graft copolymerization Reaction, react at 75°C for 4 hours, precipitate and extract with 50 parts of ethanol for 8 hours, and dry to obtain thermoplastic cellulose;

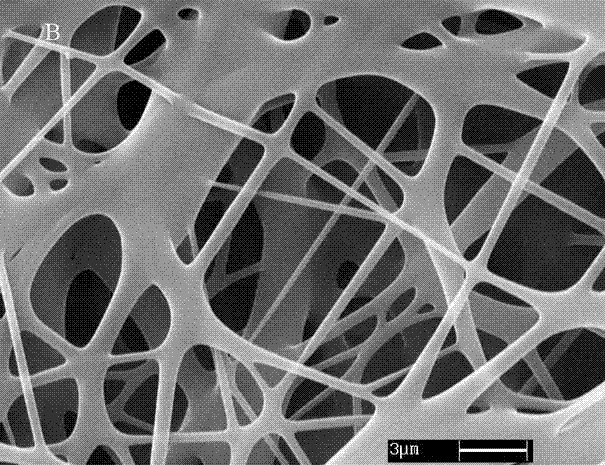

[0042] b. The prepared thermoplastic cellulose is pulverized, and the powder is dissolved in tetrahydrofuran solvent to prepare a 5% solution by weight, then the solution is fully stirred so that it is completely dissolved, and the solution is placed in an ultrasonic wave to completely separate out the bubbles. Obtain an electrospinning solution;

[0043] c. Extract the electrospinning solution prepared in step b ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com