A method for surface treatment of electroplated copper door

A surface treatment, copper door technology, applied in the direction of metal material coating process, etc., can solve the problems of low quality and poor accuracy, and achieve the effect of improving product quality, improving accuracy and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

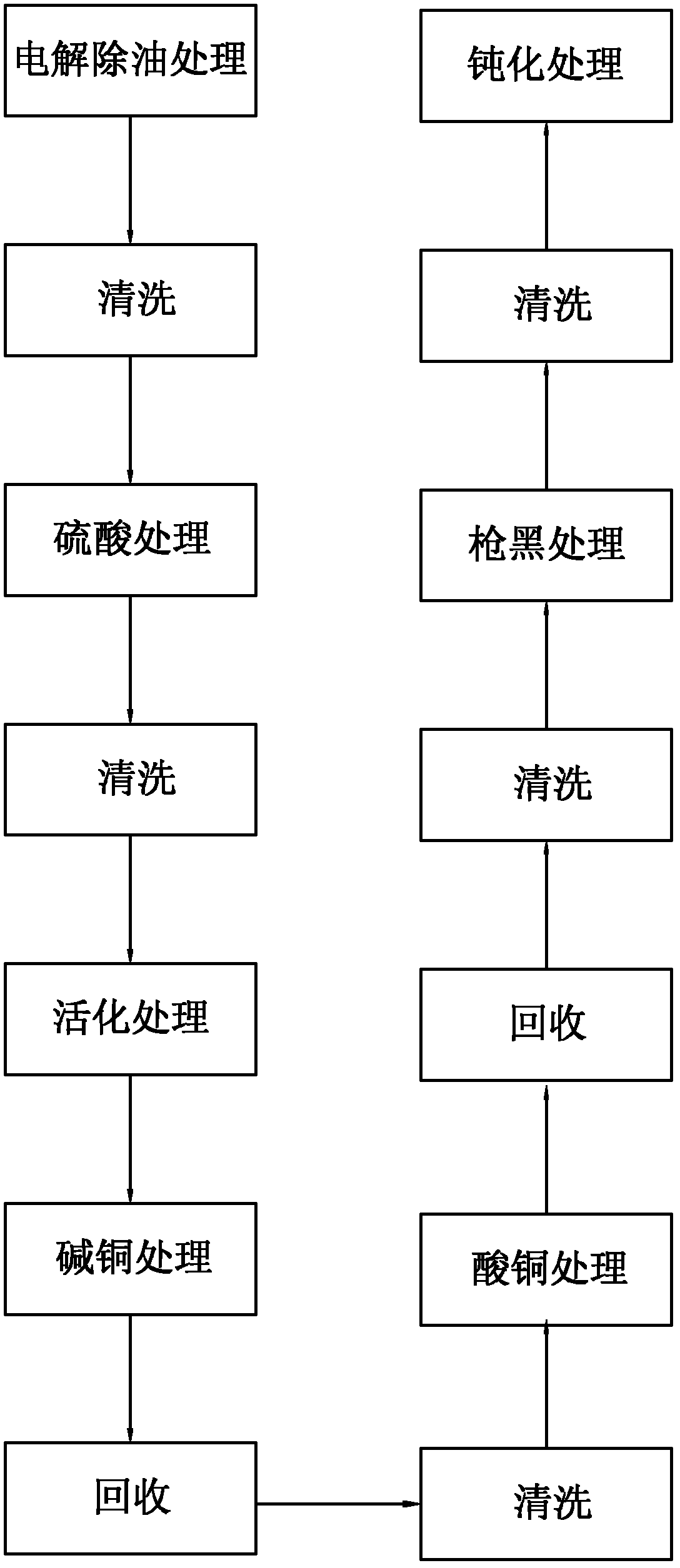

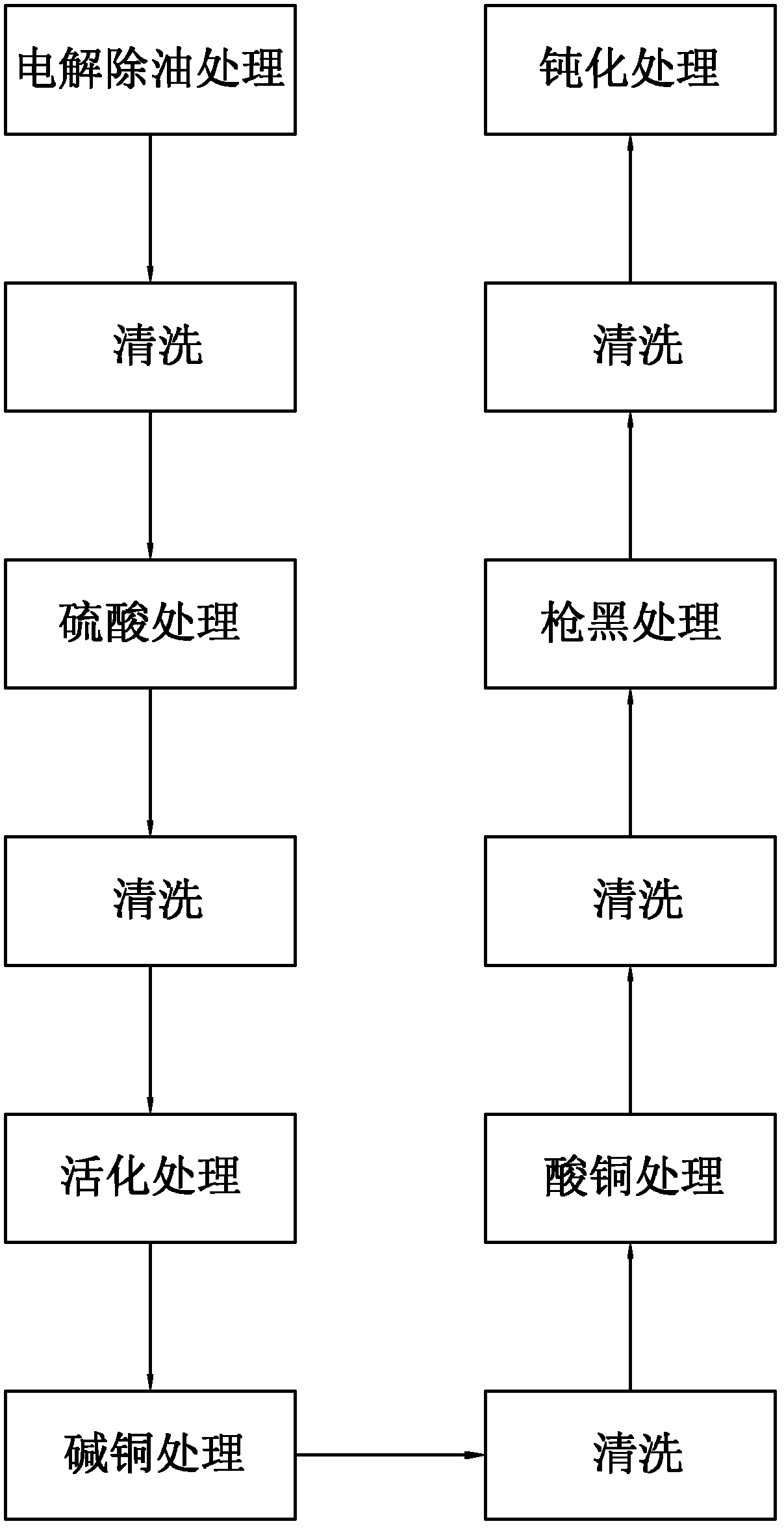

[0032] Embodiment 1: A method for surface treatment of an electroplated copper door according to the present invention, wherein,

[0033] The above method includes electrolytic degreasing of the copper door;

[0034] Clean the copper door after electrolytic degreasing;

[0035] Carry out activation treatment to the above-mentioned copper door after cleaning;

[0036] Carry out alkali copper treatment to above-mentioned copper door after activation treatment;

[0037] The above-mentioned copper door after alkali copper treatment is cleaned;

[0038] Carry out acid copper treatment to the copper door after above-mentioned cleaning;

[0039] Clean the copper door after acid copper treatment;

[0040] Carry out gun black treatment to the above-mentioned cleaned copper door;

[0041] Clean the bronze door after gun blacking;

[0042] Passivation treatment is carried out on the above-mentioned cleaned copper door.

[0043] The above electrolytic degreasing treatment is to put...

Embodiment approach 2

[0055] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is:

[0056] The above electrolytic degreasing treatment is to put the copper door into an aqueous solution with 29g / L sodium phosphate and 15g / L sodium carbonate, and the cathode current is 3A / dm 2 , and the duration is 30s.

[0057]After the last process, the copper door that has been electrolytically degreased is cleaned in two separate steps, that is, the copper door that has been electrolytically degreased is cleaned with clean water, and then cleaned again to ensure that the copper can be removed The door is clean, and the next process will not be affected by the residual impurities or residual liquid on the copper door.

[0058] Continuing to the next process, before the above activation treatment, after electrolytic degreasing and cleaning, there is also a step of sulfuric acid treatment to clean the copper door after sulfuric acid treatment. The concentration of the above sulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com