A five-element magnesium-based amorphous alloy

A technology of amorphous alloys and elements, applied in the field of five-element magnesium-based amorphous alloys, can solve problems such as increasing the formation tendency and stability of amorphous alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

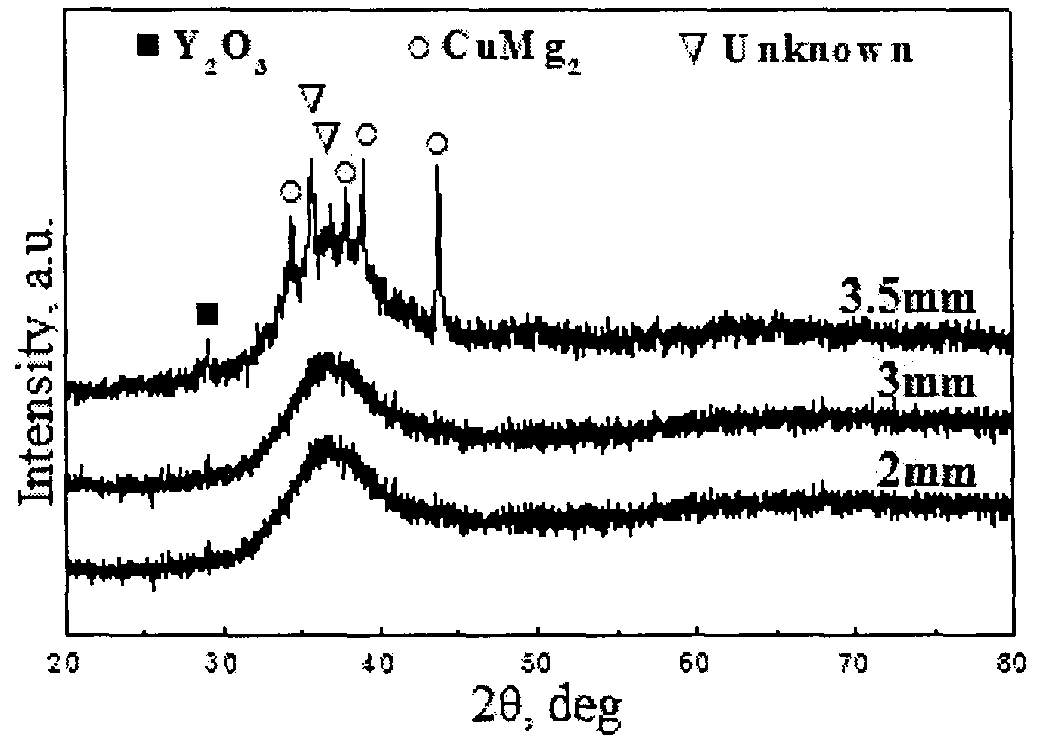

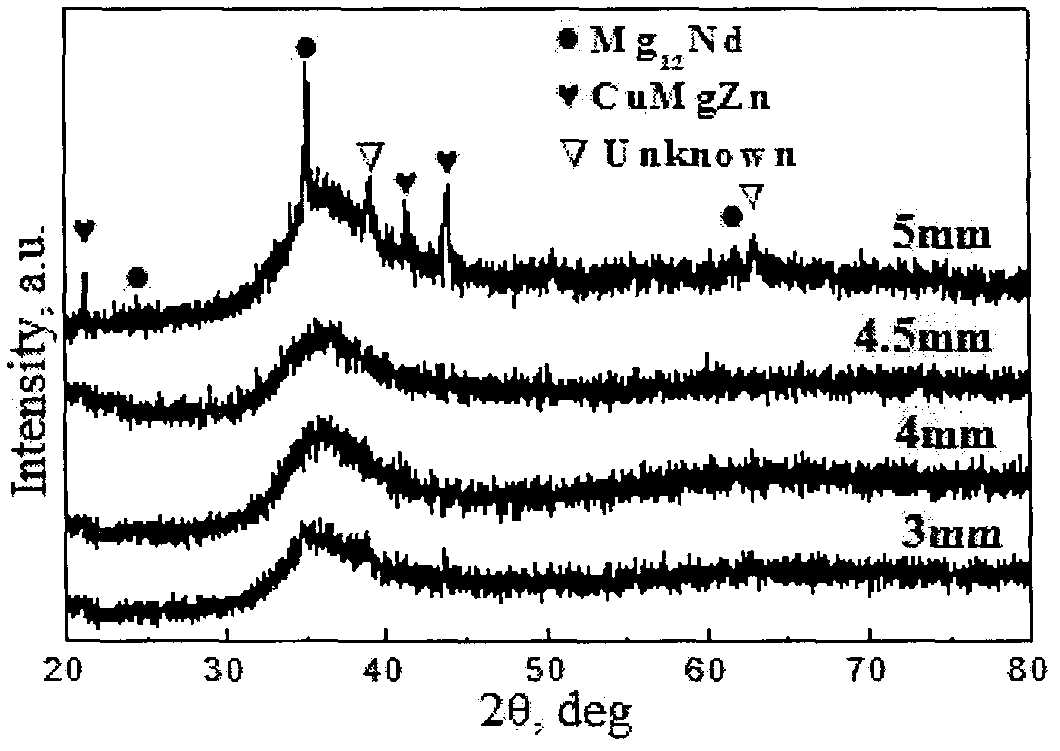

Embodiment 1

[0010] The five-element magnesium-based amorphous alloy was prepared by wedge-shaped copper mold casting method, and the Zn element was used to partially replace the Cu element, and the Nd element was used to partially replace the Y element to prepare Mg. 65 Cu 22 Zn 3 Y 5 Nd 5 Five-element magnesium-based amorphous alloy. Using commercially available high-purity (99.9% mass fraction) bulk metals as raw materials, Cu-Y is first arc-melted into an intermediate alloy, and then put into a double-ventilated air (when heating) together with pure Mg and pure Zn In a low-carbon steel crucible with inert gas protection), heat it to 750°C in a resistance furnace, keep it warm for 2 hours, shake the crucible regularly to make the alloy liquid uniform, and then pour it into a wedge-shaped copper mold that has been dried in advance . from figure 2 It can be seen that when 3% Zn is substituted for Cu and 5% Nd is substituted for Y to form Mg 65 Cu 22 Zn 3 Y 5 Nd 5 For five-elem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com