A method for reducing lead and maintaining rhenium in a high-lead rhenium-containing molybdenum concentrate

A molybdenum concentrate and high-lead technology is applied in the field of lead reduction and rhenium protection of high-lead rhenium-containing molybdenum concentrates, which can solve the problems of no high-lead-containing rhenium molybdenum concentrates and lead reduction and protection of rhenium, so as to reduce equipment investment and parameters. Easy to control, easy to malfunction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Measure 200mL of concentrated hydrochloric acid and 1800mL of industrial pure water with a concentration of 36wt%, put them into a reactor with a heating mantle and a stirring device, stir and mix evenly at room temperature to obtain a hydrochloric acid solution;

[0026] Add 82g of calcium chloride solid to the hydrochloric acid solution, and dissolve completely under stirring at room temperature to obtain a mixed solution;

[0027] The mixed solution was heated to 90°C under stirring, and 980g of high-lead rhenium-molybdenum concentrate powder was added to obtain a solid-liquid mixture 1;

[0028] Insulate the solid-liquid mixture 1 at 90°C for 90 minutes with sufficient stirring to obtain a solid-liquid mixture 2;

[0029] Filter the solid-liquid mixture 2, and wash the filtered solid with hot water at 80°C for 3 times to obtain a filter cake;

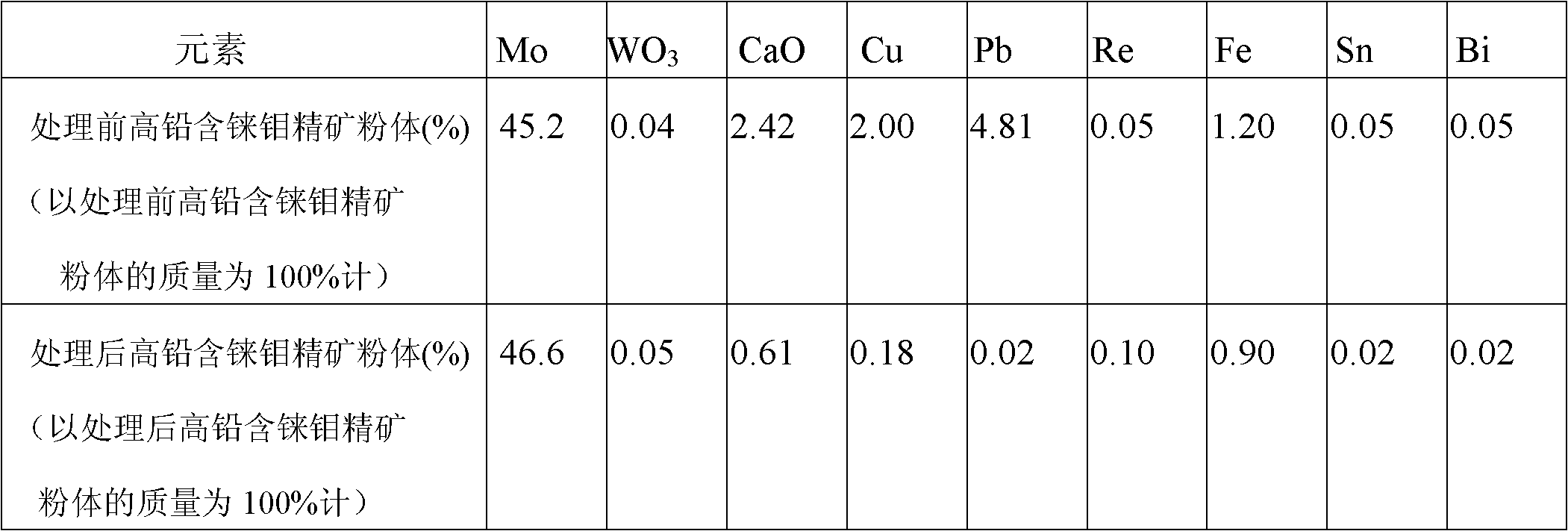

[0030] Dry the filter cake at 150°C until the moisture in the filter cake drops to 1.0g / cm 3 , the pretreated molybdenum ...

Embodiment 2

[0034] Measure 200 mL of concentrated hydrochloric acid and 980 mL of industrial pure water with a concentration of 36 wt%, put them into a reactor with a heating mantle and a stirring device, stir and mix evenly at room temperature to obtain a hydrochloric acid solution;

[0035] Add 30g of calcium chloride solid to the hydrochloric acid solution, and dissolve completely under stirring at room temperature to obtain a mixed solution;

[0036] The mixed solution was heated to 95°C under stirring, and 295g of high-lead rhenium-molybdenum concentrate powder was added to obtain a solid-liquid mixture 1;

[0037] Insulate the solid-liquid mixture 1 at 95°C for 60 minutes with sufficient stirring to obtain a solid-liquid mixture 2;

[0038] Filter the solid-liquid mixture 2, and wash the filtered solid with hot water at 90°C for 4 times to obtain a filter cake;

[0039] Dry the filter cake at 120°C until the moisture in the filter cake drops to 0.8g / cm 3 , to prepare the pretreate...

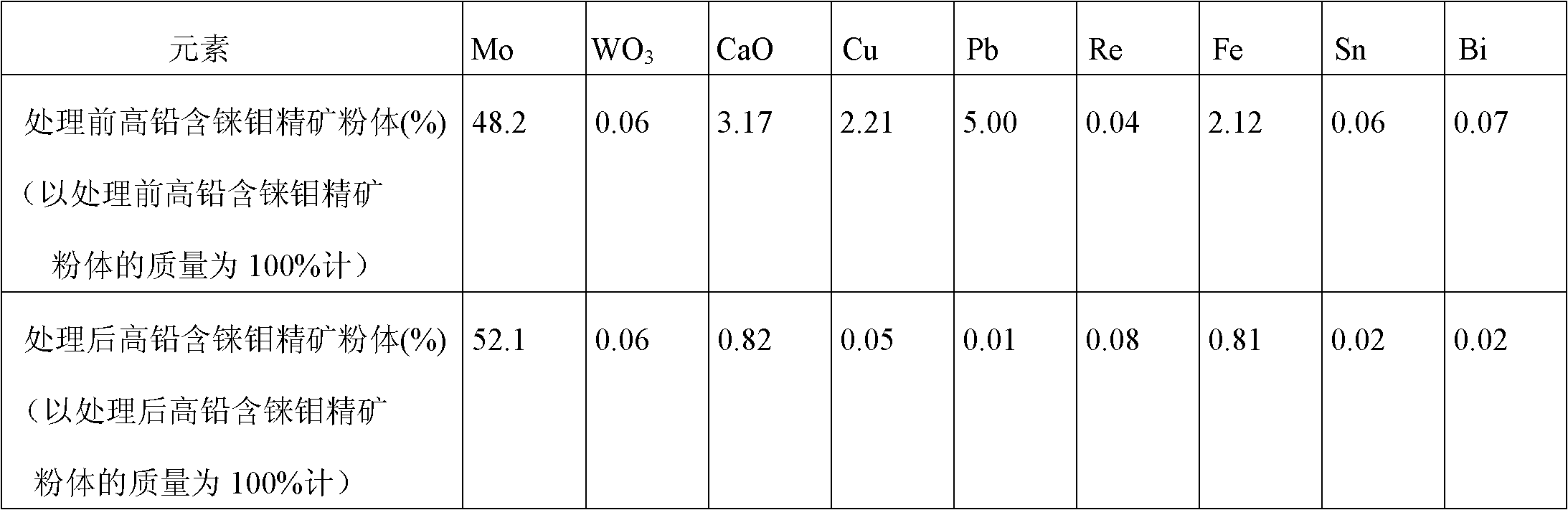

Embodiment 3

[0043] Measure 200mL of 36wt% concentrated hydrochloric acid and 1000mL of industrial pure water, put them into a reactor with a heating mantle and a stirring device, stir and mix evenly at room temperature to obtain a hydrochloric acid solution;

[0044] Add 28g of calcium chloride solid to the hydrochloric acid solution, and dissolve completely under stirring at room temperature to obtain a mixed solution;

[0045] The mixed solution was heated to 100°C under stirring, and 250g of high-lead rhenium-molybdenum concentrate powder was added to obtain a solid-liquid mixture 1;

[0046] Insulate the solid-liquid mixture 1 at 100°C for 40 minutes with sufficient stirring to obtain a solid-liquid mixture 2;

[0047] Filter the solid-liquid mixture 2, and wash the filtered solid with hot water at 100°C for 5 times to obtain a filter cake;

[0048] Dry the filter cake at 110°C until the moisture in the filter cake drops to 0.9g / cm 3 , to prepare the pretreated molybdenum concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com