Opposed jet mill sorter having modification function and mill sorting system

A technology of airflow crushing and performance function, which is applied in the field of colliding airflow crushing and sorting machines and crushing and sorting systems. Cost, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

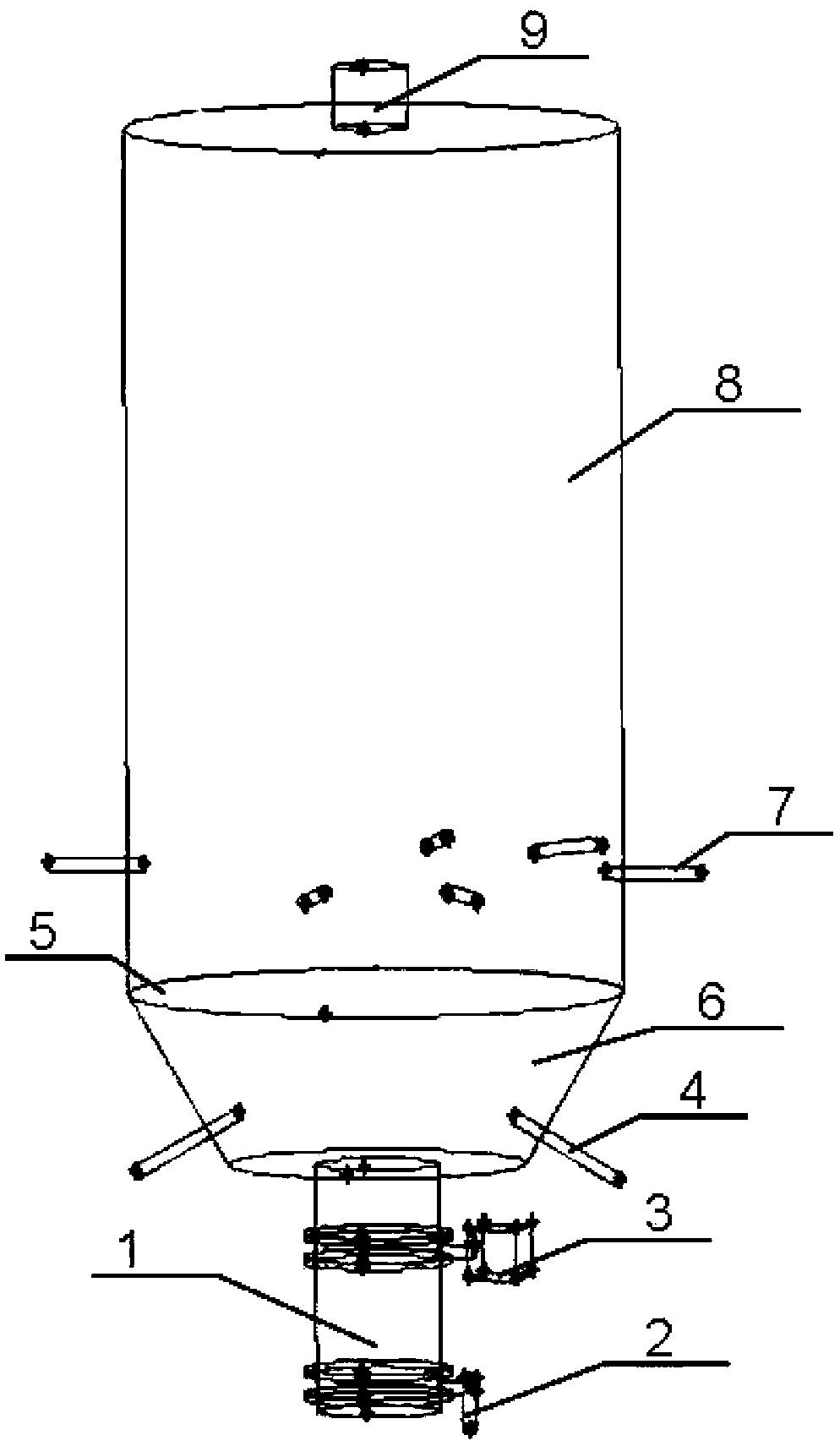

[0028] Such as figure 1 As shown, the present invention provides, for example, a colliding airflow milling and sorting machine with modification function, which includes a cavity 8, a discharge port 9 at the top of the cavity 8 and a bottom at the bottom of the cavity 8. The sorting section 6. When crushing materials, easily crushed materials are discharged from the discharge port 9 on the top after crushing, and difficult to crush materials are discharged from the bottom selection part 6, which greatly improves the crushing efficiency.

[0029] The cavity 8 in this embodiment is provided with at least one pair of feed nozzles 7, preferably three pairs of feed nozzles 7, and each pair of feed nozzles 7 is arranged on the side wall of the cavity 8 oppositely. According to the invention, the number of feeding nozzles can be opened according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com