Polyphenylene sulfide and high-temperature-resistant nylon complex and preparation method thereof

A technology of polyphenylene sulfide and high temperature resistance, which is applied in the field of material science, can solve problems affecting the scope of use, stress embrittlement, etc., achieve high continuous production efficiency, improve impact performance, and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1~ example 6

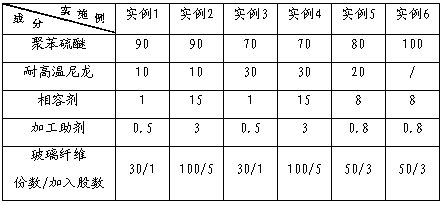

[0035] The polyphenylene sulfide is PPS-hb from Sichuan Deyang Chemical Co., Ltd., with a molecular weight of 48,000.

[0036] One or more mixtures of DSM's PA46, PA6T, and PA9T are selected for high-temperature resistant nylon.

[0037] Compatilizer is selected: example 1~example 2 all selects single maleic anhydride grafted SEBS for use, the maleic anhydride grafted SEBS and maleic anhydride grafted styrene both mixtures of example 3~example 6 are selected for use;

[0038] The processing aid is a 1:1 mixture of phenolic high-temperature antioxidant and stearic acid lubricant, of which the phenolic high-temperature antioxidant is Bruggemann's H161, and the stearic acid lubricant is Ciba Specialty Chemicals Calcium stearate.

[0039] The glass fiber is the alkali-free fiber of Jushi Group, 988A type, and the number of glass fibers added is controlled by adjusting the speed of the host.

[0040] Weigh each component according to the ratio in the table below in parts by weigh...

PUM

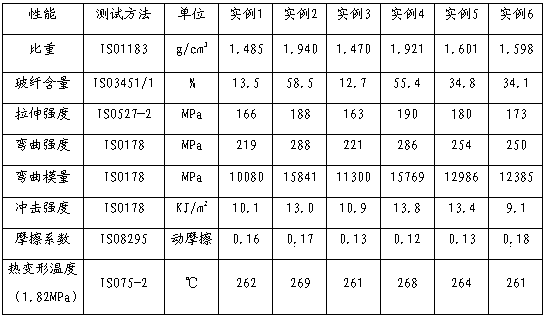

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com