Electroplating bath and method

A technology of copper electroplating solution and leveling agent, applied in the field of copper electroplating and electroplating metal, can solve the problem of not being able to provide smooth copper deposition, and achieve the effect of reducing nodules and good dispersing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

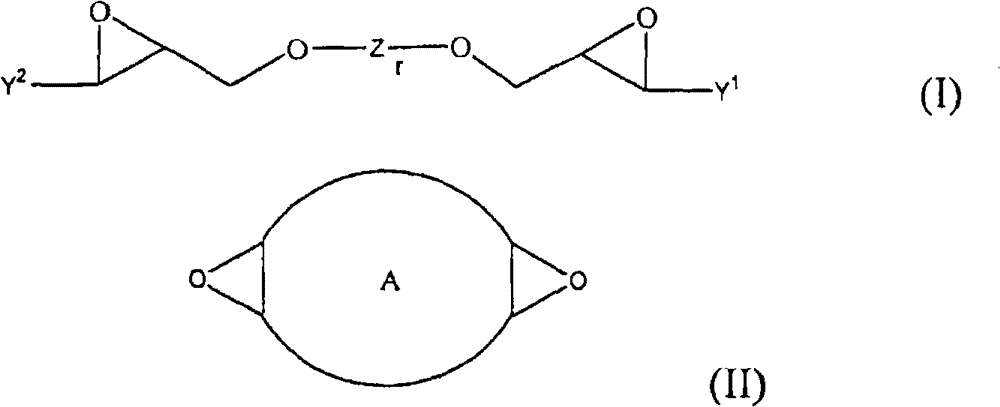

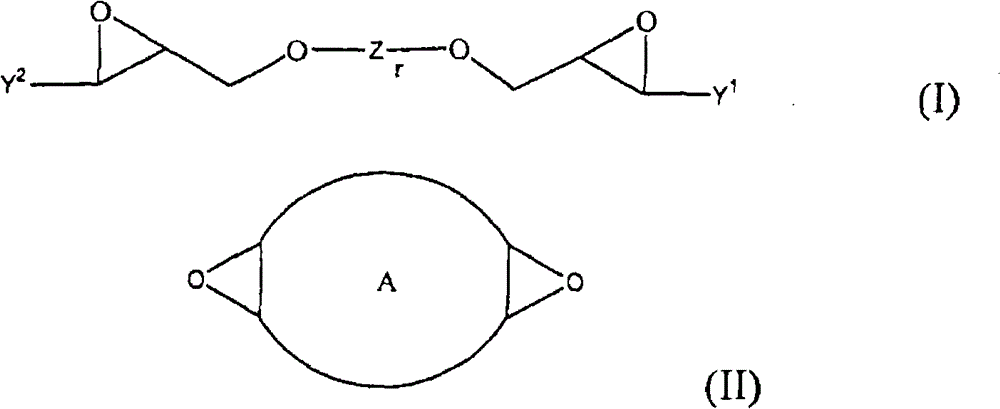

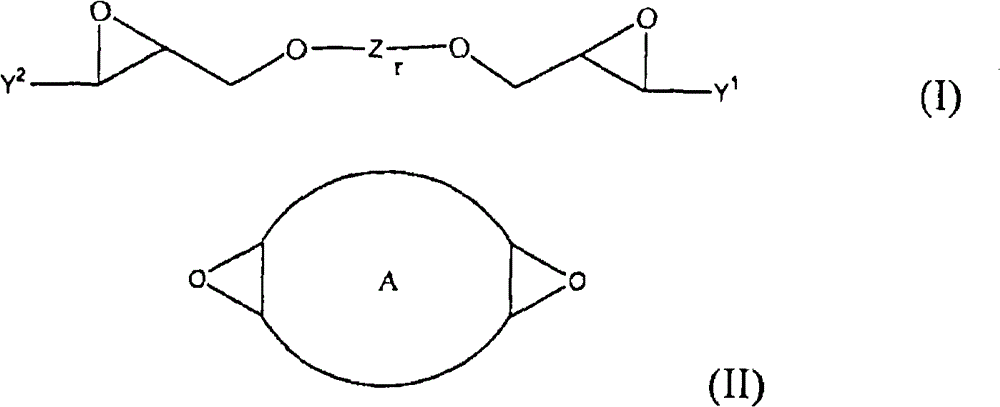

Method used

Image

Examples

Embodiment 1

[0064] Resorcinol diglycidyl ether (94.5 mmol), 150 mmol of imidazole and 10 mL of diethylene glycol were added to a round-bottom reaction flask placed in a thermal bath at room temperature. Then 40 mL of DI water was added to the reaction vial. The temperature of the heating bath was set to 98°C. The initially formed white suspension eventually dissolved and formed a clear amber solution as the reaction temperature was increased. The reaction mixture was then heated for 5 hours and left to stir at room temperature for an additional 8 hours. The reaction product (reaction product 1) was used without purification. The characteristic parameters of the reaction products are shown in Table 1. Stock solutions of this product were prepared in water as solvent.

Embodiment 2

[0066] Add 2,4-dimethylimidazole (100mmol), 56.7mmol 1,4-butanediol diglycidyl ether and 6.3mL resorcinol diglycidyl ether to a round bottom reaction flask placed in a thermal bath at room temperature . Then 15 mL of DI water was added to the reaction flask. The temperature of the heating bath was set to 95°C. The mixture was then heated for 6 hours and left with stirring at room temperature for an additional 8 hours. The reaction product (amber) was used without purification (reaction product 9). The characteristic parameters of the reaction products are shown in Table 1. A stock solution of this product was prepared in DI water as solvent.

Embodiment 3

[0068] Reaction products 2-8 were prepared according to the steps of Example 1 or 2. The molar ratios and characteristic parameters of the components are shown in Table 1. Measure the UV absorption spectrum of the reaction product in water using an Agilent 8453 spectrophotometer and record λ in the following table max (nm).

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com