Fermentation composite fertilizer suitable for greenhouse vegetable planting and preparation method thereof

A compound fertilizer and vegetable technology, which is applied to the preparation of organic fertilizers, fertilizers made from biological waste, organic fertilizers, etc., can solve problems such as large impacts on climate and weather, high levels of antibiotics and heavy metals, and limited production capacity, and achieve improved Crop quality, obvious fertilizer effect, and balanced fertilizer supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

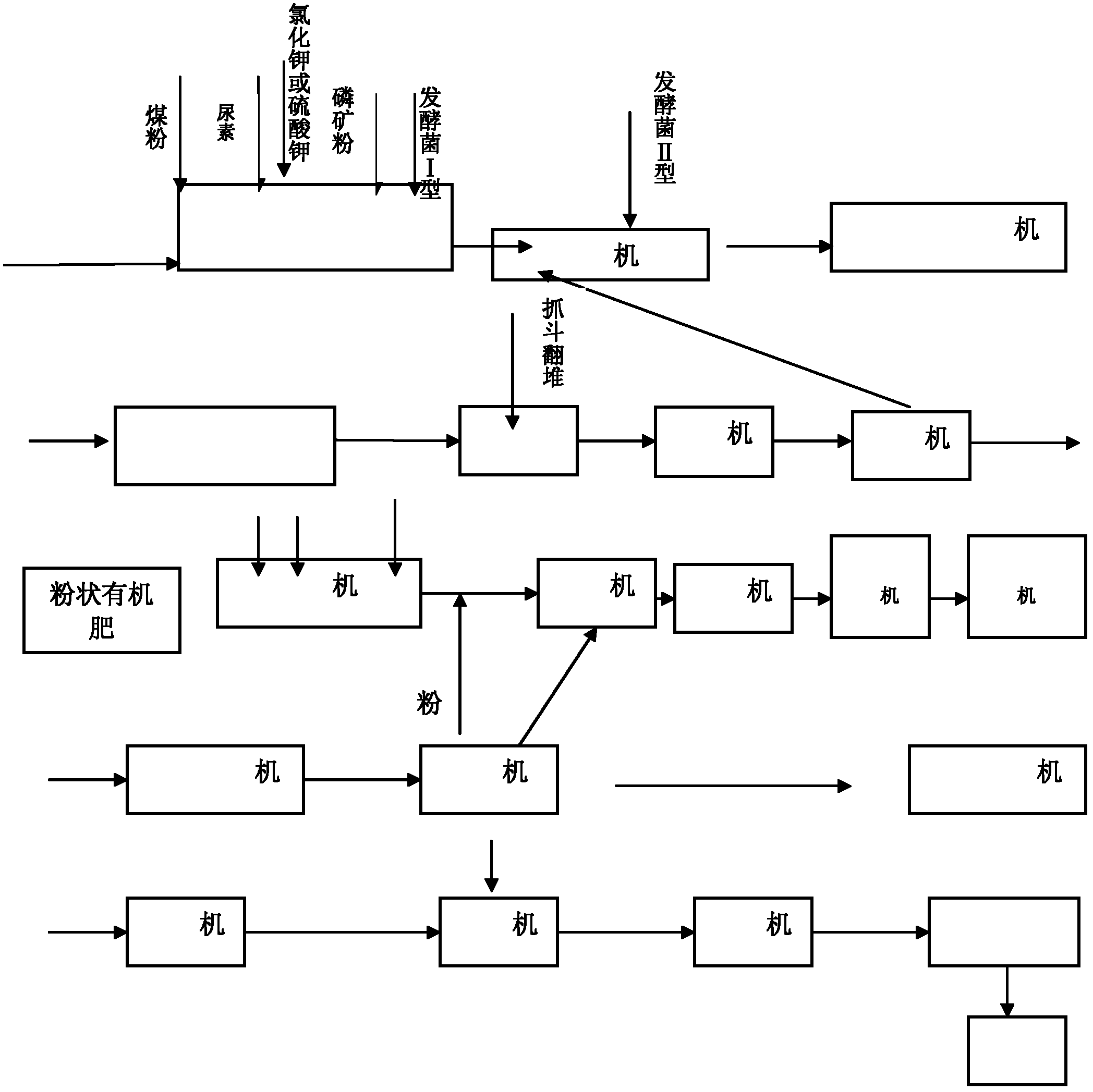

Method used

Image

Examples

Embodiment 1

[0086] Prepare the fermented compound fertilizer applicable to greenhouse vegetable cultivation according to the following steps

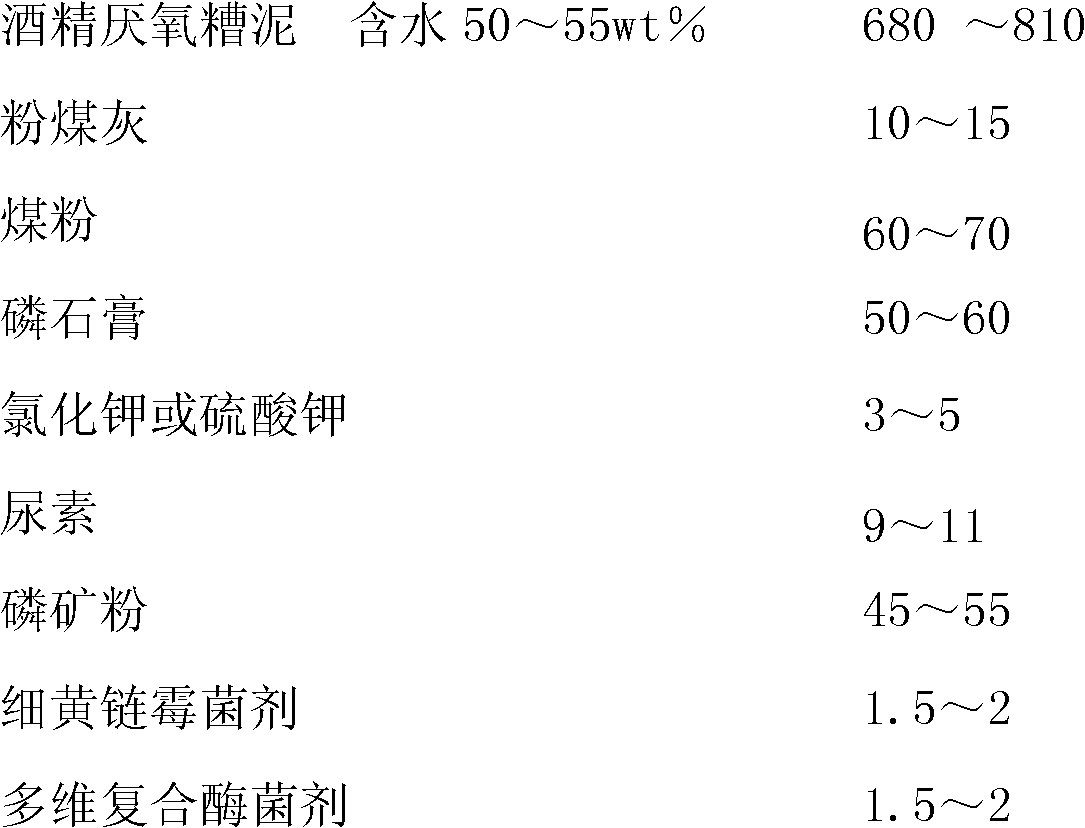

[0087] ①. Raw material measurement and mixing

[0088] Accurately measure 700 parts by weight of anaerobic sludge, 15 parts by weight of fly ash, 70 parts by weight of pulverized coal, 5 parts by weight of potassium chloride or potassium sulfate, and 11 parts by weight of urea from the alcohol aerobic fermentation device plate. Parts by weight, 55 parts by weight of phosphate rock powder and produced and sold by Beijing Jingpuyuan Bioengineering Co., Ltd., the trade name is AM-1 1.5 parts by weight, control C / N=20~30, pH=5.5~8, mix evenly, Prepare stacks;

[0089] ②. Intermittent stacking, aerobic fermentation

[0090] Stack the raw materials mixed in step ① intermittently, and carry out an aerobic fermentation in a natural environment. After the water content of the material drops to 40-45%, the first aerobic fermentation ends; prepare for the s...

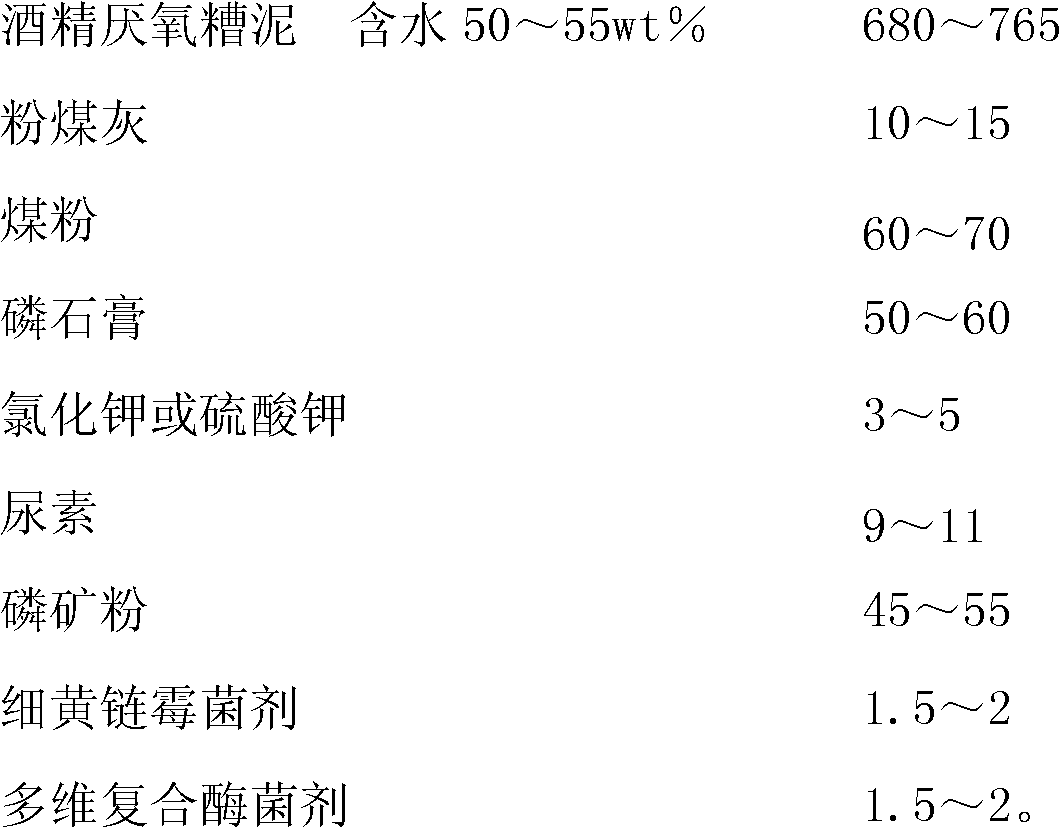

Embodiment 2~ Embodiment 6

[0098] Prepare powdery fertilizer according to the method and step of embodiment, then according to the raw material formula in table and table 2, according to the following steps, prepare the nutrient-enhanced granular fermented compound fertilizer applicable to greenhouse vegetable planting of the present invention

[0099] ①. Granulation

[0100] Accurately measure 800-850 parts by weight of powdery fermented compound fertilizer, 25-30 parts by weight of ammonium sulfate, 50-75 parts by weight of phosphogypsum, and 50-75 parts by weight of granulation binder, and transport them to the drum after mixing, stirring and crushing Water steam spray granulation in the granulator;

[0101] ②.Drying, cooling, screening

[0102] After step ①, the granulated material is dried at a low temperature of 60°C-70°C (tail temperature) once, cooled once, sieved once, and then dried at a low temperature of 50°C-60°C (temperature at the tail end) twice. Secondary cooling and secondary screeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com