Oxide up-conversion luminescence piezoelectric material of bismuth lamellar perovskite structure and preparation method thereof

A technology of perovskite structure and piezoelectric materials, applied in the field of oxide up-conversion luminescent piezoelectric materials and its preparation, can solve the problems of high cost, unreported up-conversion luminescence characteristics, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

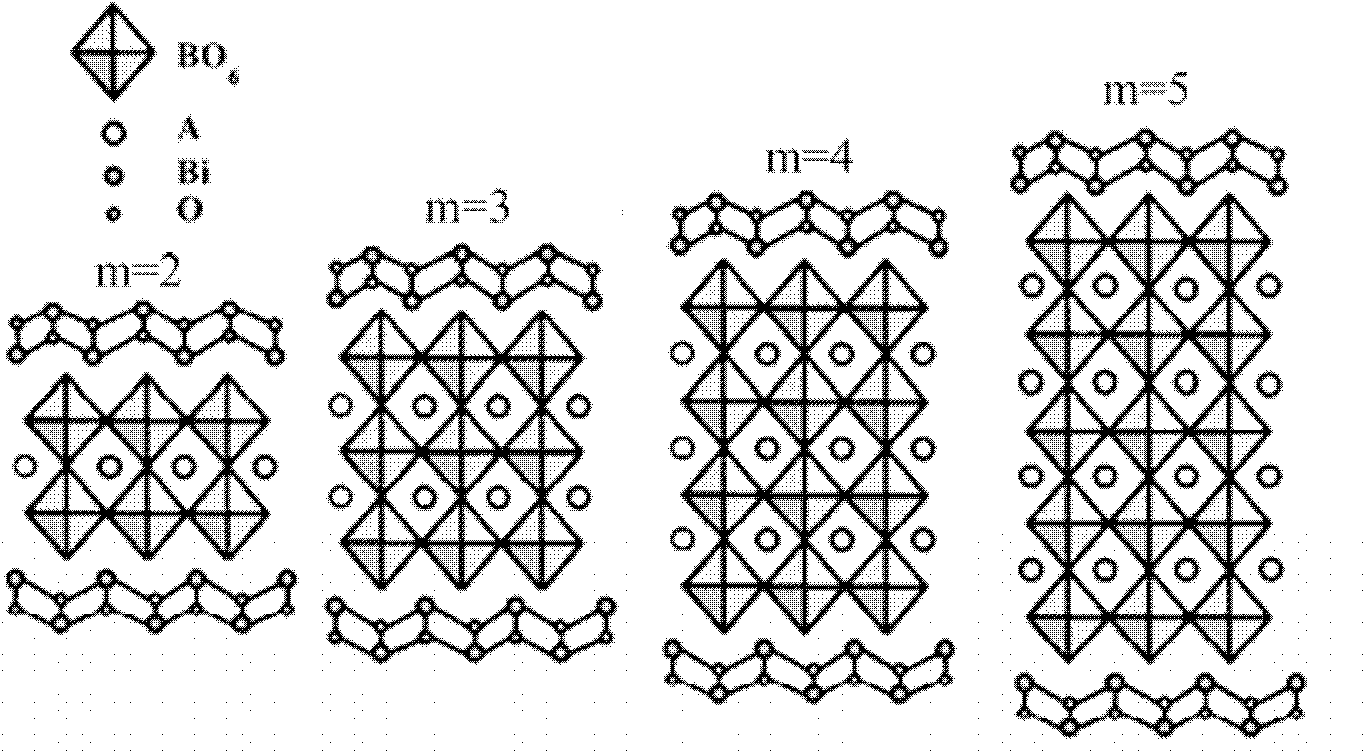

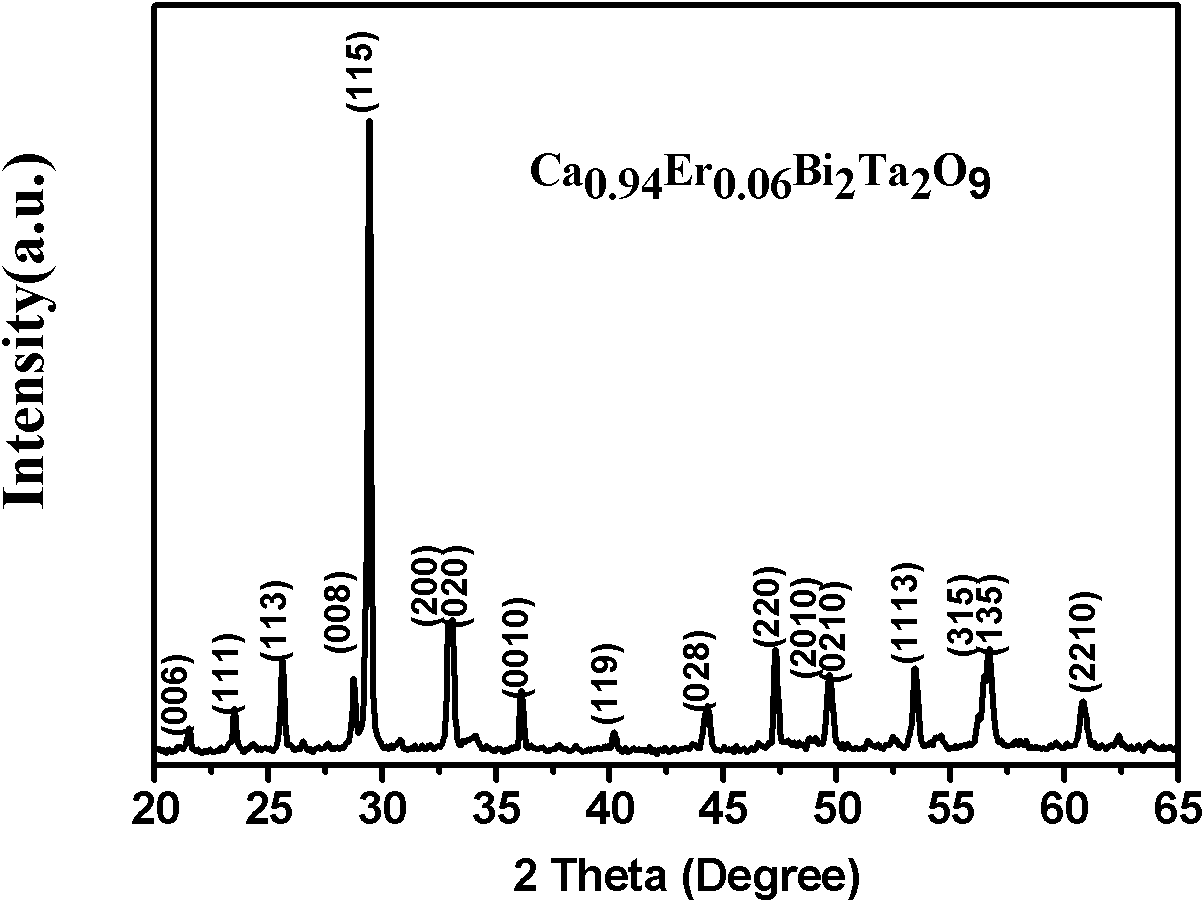

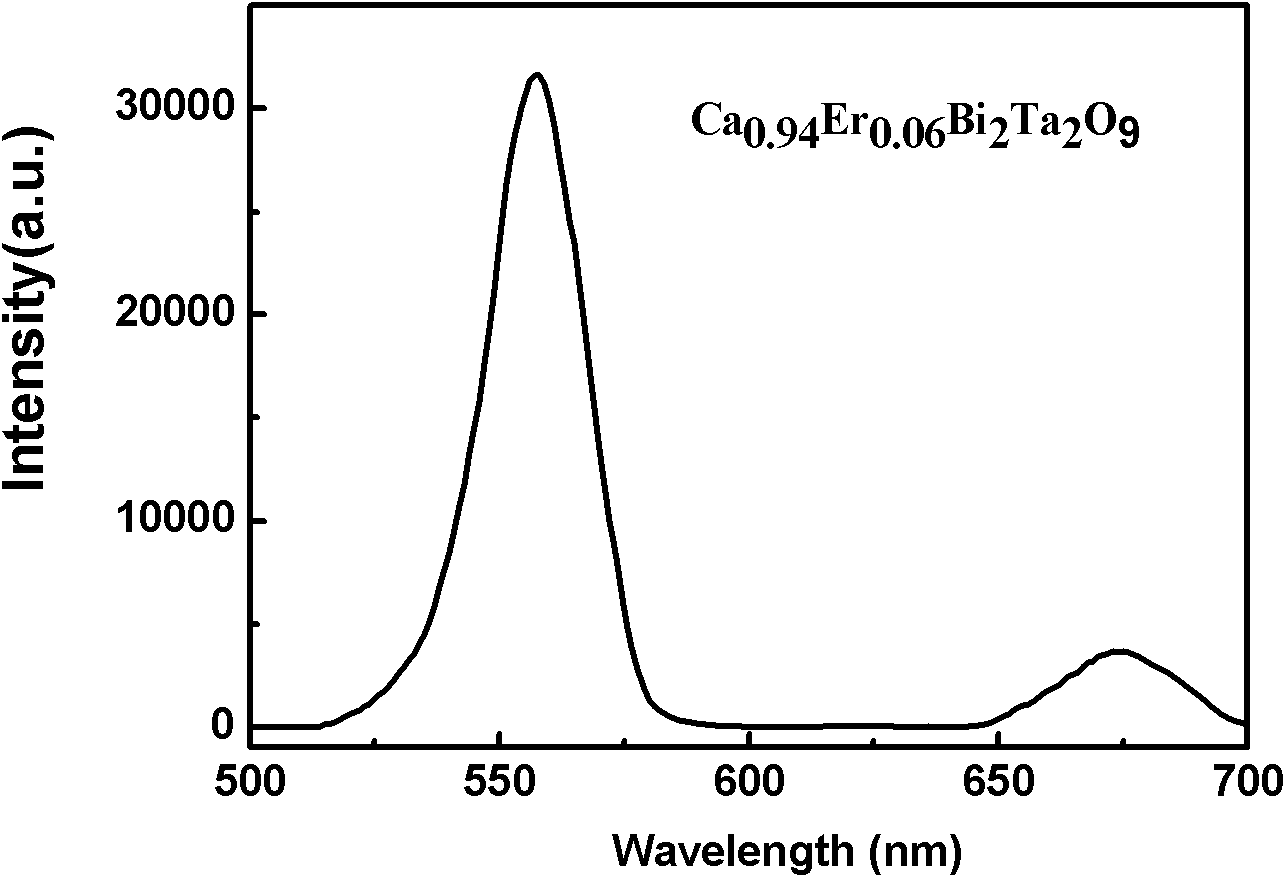

[0036] Ca Bi 2 Ta 2 o 9 The host lattice perovskite layer (A m-1 B m o 3m+1 ) 2- Preparation of up-conversion luminescent piezoelectric ceramic powder material sample Ca by doping Er in middle A site 0.94 Er 0.06 Bi 2 Ta 2 o 9 .

[0037] Raw material selection CaCO 3 、Er 2 o 3 、 Bi 2 o 3 and Ta 2 o 5 , by Ca 0.94 Er 0.06 Bi 2 Ta 2 o 9 The stoichiometric ratio of Ca, Er, Bi and Ta elements in the formula is to weigh the selected raw materials, weigh the raw materials and mix them, add absolute ethanol, grind in a mortar and mix well to obtain powder A, wherein the absolute ethanol and raw material mixture The mass ratio is 3:1. Put the powder A in an alumina crucible for pre-calcination, the pre-fire temperature is 850°C, the heating rate is 3°C / min, keep it warm for 2 hours and cool naturally to get the pre-fire powder B. After grinding the calcined powder B, sinter it at a temperature of 1200°C for 4 hours at a heating rate of 3°C / min, cool it naturall...

Embodiment 2

[0041] Ca Bi 2 Ta 2 o 9 The host lattice perovskite layer (A m-1 B m o 3m+1 ) 2- Preparation of upconversion luminescence piezoelectric ceramic bulk material Ca by doping Er in middle A site 0.94 Er 0.06 Bi 2 Ta 2 o 9 .

[0042] Raw material selection CaCO 3 、Er 2 o 3 、 Bi 2 o 3 and Ta 2 o 5 , by Ca 0.94 Er 0.06 Bi 2 Ta 2 o 9 The stoichiometric ratio of the elements Ca, Er, Bi and Ta in the medium is to weigh the selected raw materials, add absolute ethanol after weighing the raw materials and mix them, grind them in a mortar and mix thoroughly to obtain powder A, wherein the absolute ethanol and raw material mixture The mass ratio is 2:1. Put the powder A in an alumina crucible for pre-calcination, the pre-fire temperature is 850°C, the heating rate is 3°C / min, keep it warm for 2 hours and cool naturally to get the pre-fire powder B. After grinding the calcined powder B, granulate it with 10% polyvinyl alcohol PVA as a binder, and then press it into a ...

Embodiment 3

[0046] Ca Bi 2 Ta 2 o 9 The host lattice perovskite layer (A m-1 B m o 3m+1 ) 2- Preparation of up-conversion luminescent piezoelectric material Ca by doping Er in A site and Yb in B site 0.82 Er 0.06 Yb 0.12 Bi 2 Ta 2 o 9 Ceramic powder materials and ceramic bulk materials.

[0047] Raw material selection CaCO 3 、Er 2 o 3 , Yb 2 o 3 、 Bi 2 o 3 and Ta 2 o 5 , by Ca 0.82 Er 0.06 Yb 0.12 Bi 2 Ta 2 o 9 The stoichiometric ratio of elements Ca, Er, Yb, Bi and Ta in the medium is weighed from selected raw materials. Prepare the up-conversion ceramic powder Ca of this embodiment 0.82 Er 0.06 Yb 0.12 Bi 2 Ta 2 o 9 The rest of the steps are consistent with Example 1; the up-conversion ceramic block sample Ca of the present embodiment is prepared 0.94 Er 0.06 Bi 2 Ta 1.88 Yb 0.12 o 9 : After mixing the weighed raw materials, add absolute ethanol to grind in a mortar and mix thoroughly to obtain powder A, wherein the mass ratio of absolute ethanol to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com