A kind of phosphogypsum wall brick and preparation method thereof

A technology of gypsum wall and phosphogypsum, which is applied in the field of phosphogypsum wall bricks and its preparation, can solve the problems that harmful impurities cannot be removed, phosphogypsum raw materials are not pretreated, and the performance of products is affected, so as to realize the comprehensive utilization of building materials resources , Improve the compactness and softening coefficient, and eliminate the effect of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

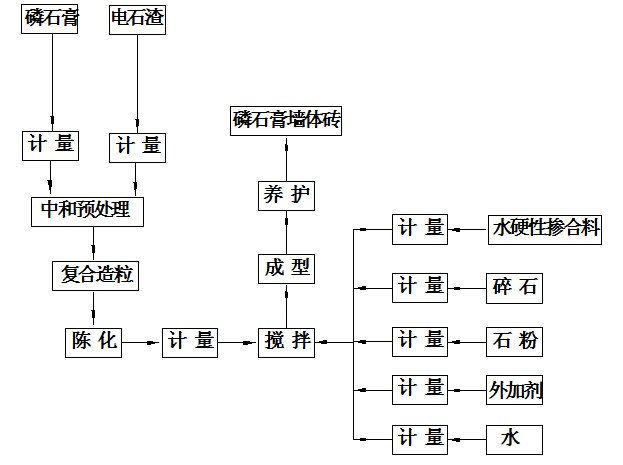

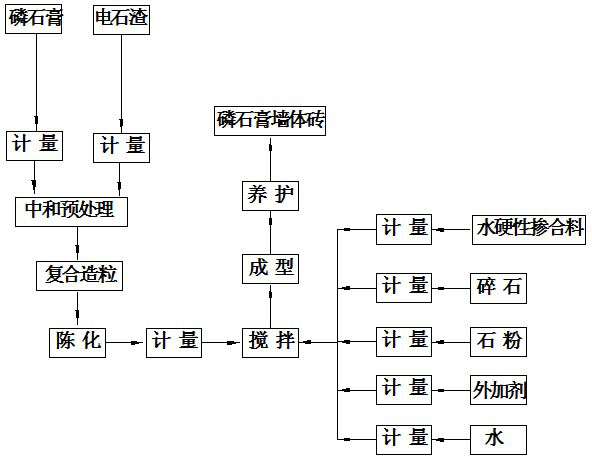

Method used

Image

Examples

Embodiment 1

[0022] The phosphogypsum wall brick provided in this example is made of the following raw materials in parts by weight: 100 parts of phosphogypsum, 10 parts of carbide slag, 12 parts of hydraulic admixture, 5 parts of rough stone, 10 parts of stone powder, Yuan Ming 1.5 parts of powder, 3 parts of water glass, 0.2 parts of calcium formate, 4 parts of calcium lignosulfonate. Among them, phosphogypsum is granular, which can be used as inert aggregate in the product.

[0023] The preparation method of the phosphogypsum wall brick is as follows: mixing and stirring phosphogypsum and carbide slag, and spraying with water mist; granulating the mixture of phosphogypsum and carbide slag to obtain spherical particles with a particle size of 8 -15mm, and air-dry under natural conditions; mix spherical particles with hydraulic admixtures, aggregates and admixtures, add water and stir to form a uniform slurry; inject the slurry into a molding machine for compression molding, and the moldi...

Embodiment 2

[0026] The phosphogypsum wall brick provided in this example is made of the following raw materials in parts by weight: 100 parts of phosphogypsum, 6 parts of carbide slag, 15 parts of hydraulic admixture, 8 parts of rough stone, 16 parts of stone powder, Yuan Ming 2 parts of powder, 4 parts of water glass, 0.1 part of calcium formate, 2 parts of calcium lignosulfonate.

[0027] The preparation method of the phosphogypsum wall brick is as follows: mixing and stirring phosphogypsum and carbide slag, and spraying with water mist; granulating the mixture of phosphogypsum and carbide slag to obtain cube-shaped particles with a particle size of 9 -20mm, and air-dry under natural conditions; mix spherical particles with hydraulic admixtures, aggregates and admixtures, add water and stir to form a uniform slurry; inject the slurry into a molding machine for compression molding, and the molding pressure is 20MPa; The formed products are naturally cured to produce phosphogypsum wall br...

Embodiment 3

[0030] The phosphogypsum wall brick provided in this example is made of the following raw materials in parts by weight: 100 parts of phosphogypsum, 8 parts of carbide slag, 8 parts of hydraulic admixture, 7.5 parts of rough stone, 15 parts of stone powder, Yuan Ming 0.5 parts of powder, 5 parts of water glass, 0.05 parts of calcium formate, 6 parts of calcium lignosulfonate.

[0031] The preparation method of the phosphogypsum wall brick is as follows: mixing and stirring phosphogypsum and carbide slag, and spraying with water mist; granulating the mixture of phosphogypsum and carbide slag to obtain tetrahedral particles with a particle size of 9- 20mm, and air-dried under natural conditions; mix spherical particles with hydraulic admixtures, aggregates and admixtures, add water and stir to form a uniform slurry; inject the slurry into a molding machine for compression molding, and the molding pressure is 8MPa; The formed products are naturally cured to obtain phosphogypsum wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com