Reverse osmosis concentrated water treatment process and treatment system in cold rolling steel plant

A technology of reverse osmosis concentrated water and treatment process, which is applied in the field of reverse osmosis concentrated water treatment process and its treatment system in cold rolling steel mills. It can solve the problems of increasing project investment and wastewater treatment operation costs, and achieves simple structure and stable operation. , obvious economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

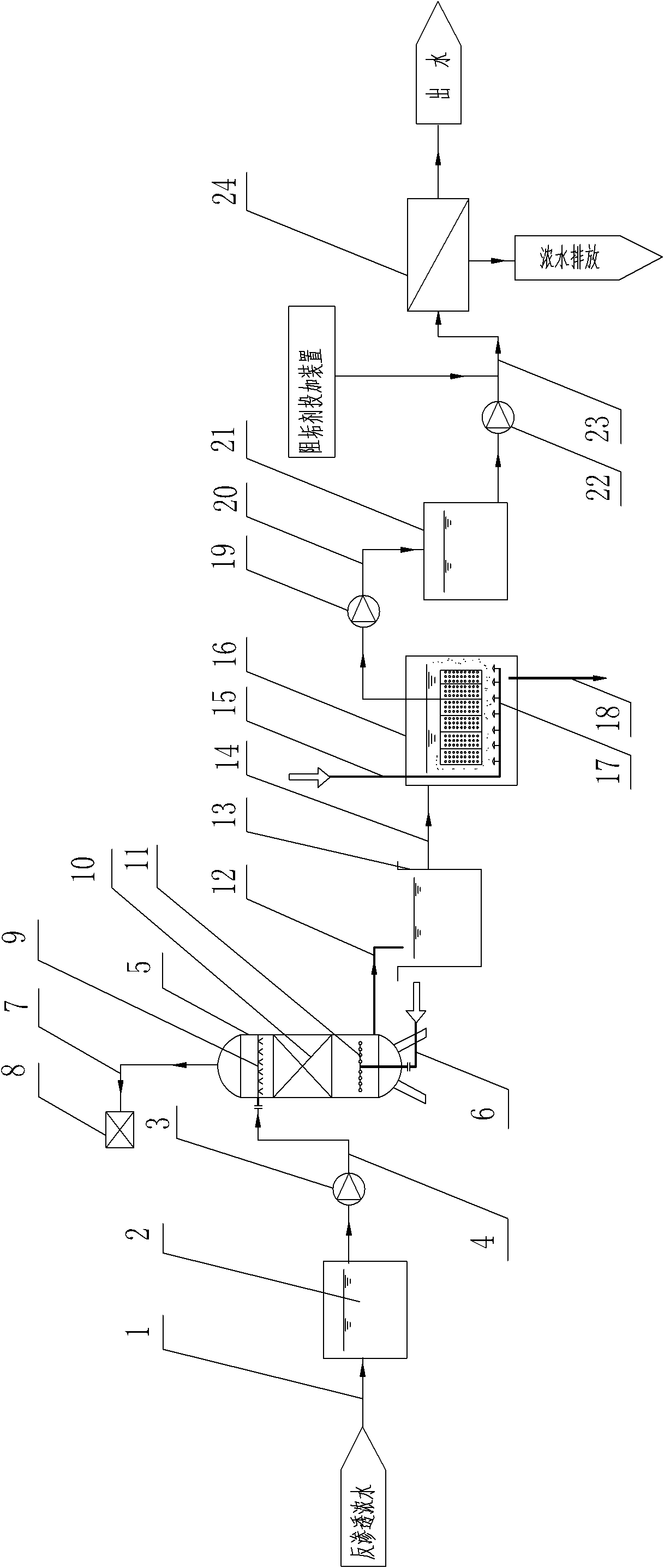

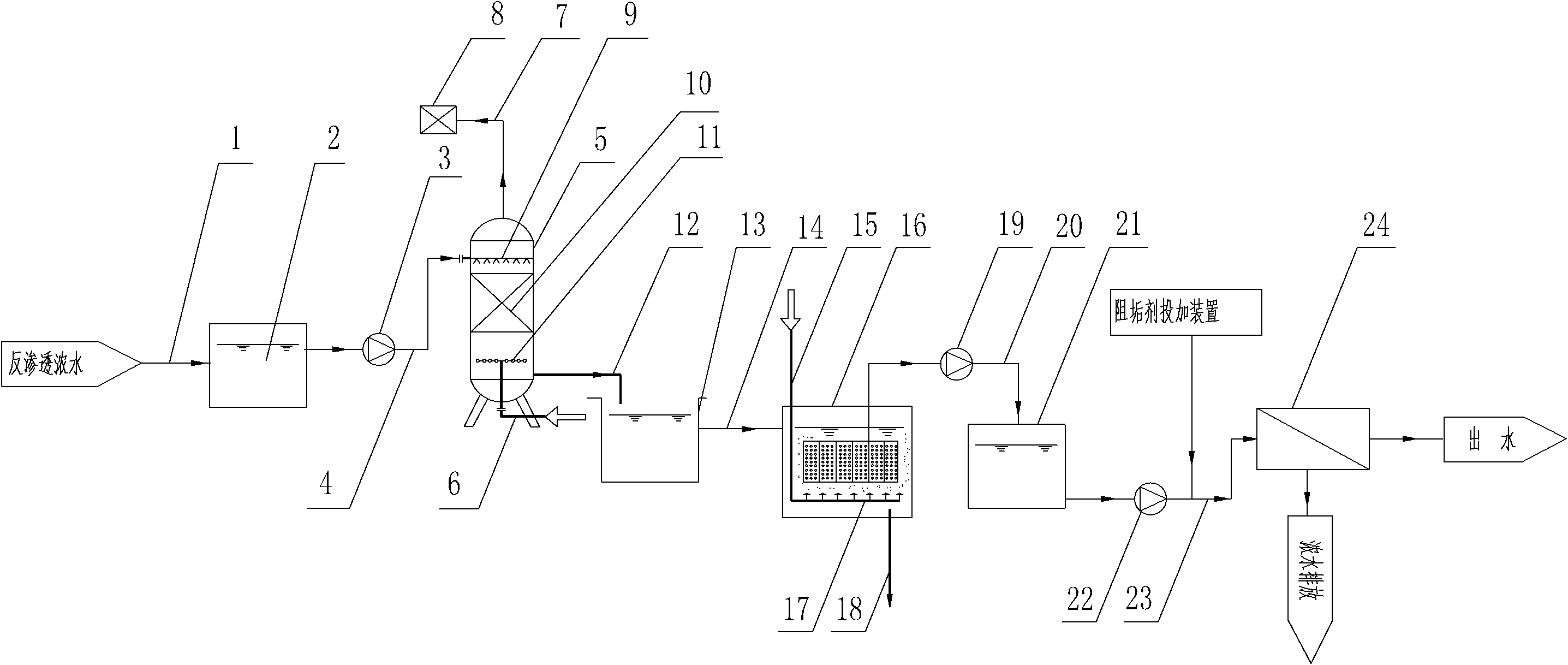

[0023] The reverse osmosis concentrated water treatment process in cold rolling steel mills includes the following steps:

[0024] 1) Concentrated reverse osmosis water (first-stage reverse osmosis concentrated water) first enters the regulating tank (wastewater stays in the regulating tank for 4 to 6 hours, the main function is to resist impact load and homogenize water quality), and the reverse osmosis treated by the regulating tank Infiltrate the concentrated water into the ozone contact reactor, use the strong oxidizing property of ozone to inorganicize or degrade the difficult biodegradable organic substances in the reverse osmosis concentrated water into biochemical substances, and decompose the macromolecular organic substances into small molecular organic substances;

[0025] 2) The effluent treated by the ozone contact reactor enters the attenuation pool (note that there is no need to add anything to the attenuation pool). After passing through the attenuation pool, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com