Treatment method of alkaline oily wastewater with demulsifier

A treatment method and demulsifier technology, applied in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc., can solve secondary pollution and other problems, and achieve simple and strong dosing Effect of surface activity and low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

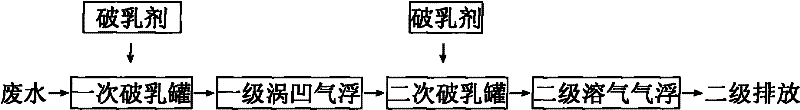

Image

Examples

Embodiment 1

[0026] Step 1, preparation of demulsifier: proportioning by weight percentage of the following raw materials:

[0027] Calcium chloride 0.05-0.5%, polyferric sulfate 0.1-1.5%, polyaluminum chloride 0.5-3.0%, cationic polyacrylamide 0.01-0.1%, and the rest is water. Slowly add the above raw materials in sequence under normal temperature and pressure, and evenly Stir and dissolve in water to prepare a demulsifier for ready-to-use liquid products;

[0028] Step 2. Primary demulsification: the wastewater to be treated enters the primary demulsification tank. The dosage of primary demulsifier is 0.5-3.0ml / L per liter of treated wastewater. The pH of the water quality is controlled between 7-11, and the water temperature is controlled At 10-65°C, and stirring at a stirring speed of 40-100rpm, the residence time of the primary demulsifier in the wastewater is controlled within 5-21min;

[0029] Step 3, first-level vortex air flotation: the mixed liquid after the above pretreatment e...

Embodiment 2

[0033] Step 1, prepare a demulsifier, take mass fraction of calcium chloride 0.20%, polyferric sulfate 1.25%, polyaluminum chloride 2.0%, cationic polyacrylamide 0.02%, and the rest is water; at normal temperature and pressure, dissolve in water in sequence spare;

[0034] Step 2. Primary demulsification: The dosage of primary demulsifier is 2.0ml / L per liter of treated wastewater, the pH of water quality is controlled to 8.5, the water temperature is controlled at 45°C, and the stirring speed is 50rpm. The primary demulsifier is added to the waste water The residence time is controlled at 10min;

[0035] Step 3, first-level vortex air flotation: same as step 3 in Example 1, the effluent water is analyzed with a sewage removal rate of 90%, and the effluent water is clear;

[0036] Step 4, preparing a secondary demulsifier, taking mass fractions of calcium chloride 0.10%, polyferric sulfate 0.55%, polyaluminum chloride 1.00%, cationic polyacrylamide 0.01%, and the rest is wate...

Embodiment 3

[0039] Step 1, prepare a demulsifier, take 0.10% of calcium chloride, 1.50% of polyferric sulfate, 1.70% of polyaluminum chloride, 0.01% of cationic polyacrylamide in mass fraction, and the rest is water; at normal temperature and pressure, dissolve in water in sequence spare;

[0040] Step 2. Primary demulsification: The dosage of primary demulsifier is 2.5ml / L per liter of treated wastewater, the pH of water quality is controlled to 7.5, the water temperature is controlled at 62°C, and the stirring speed is 40rpm. The primary demulsifier is added to the waste water The residence time is controlled at 15min;

[0041] Step 3, one-stage vortex-concave air flotation: same as step 3 in Example 1, the effluent is analyzed with a sewage removal rate of 88%;

[0042] Step 4, prepare the secondary demulsifier, take mass fraction of calcium chloride 0.15%, polyferric sulfate 0.35%, polyaluminum chloride 1.55%, cationic polyacrylamide 0.02%, and the rest is water, which is dissolved i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com