Municipal refuse low-temperature oxygen-free carbonization system equipment and low-temperature oxygen-free carbonization revolving furnace therefor

A technology of carbonization system and anoxic carbonization part, which is applied in the chemical industry, tar processing, liquid carbon-containing fuel, etc., can solve the problems of secondary pollution of the surrounding environment, damage to the living environment and health of human beings, and achieve recycling, The effect of zero emission and social benefits of energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

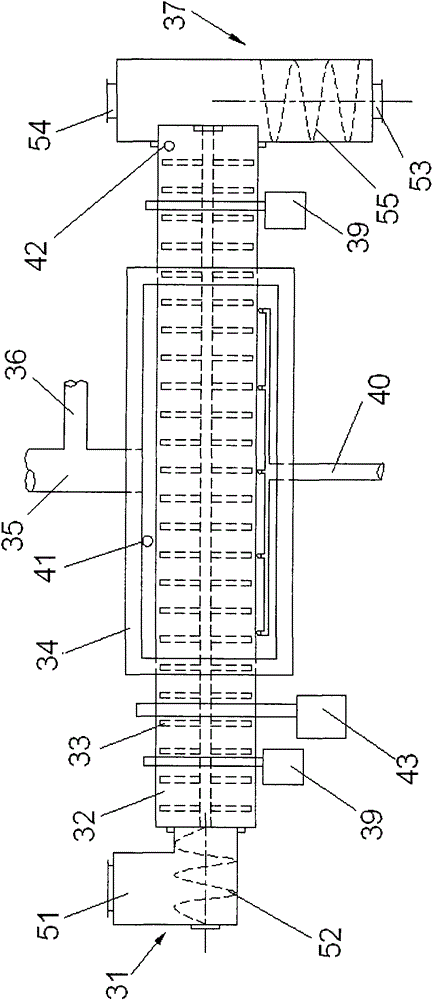

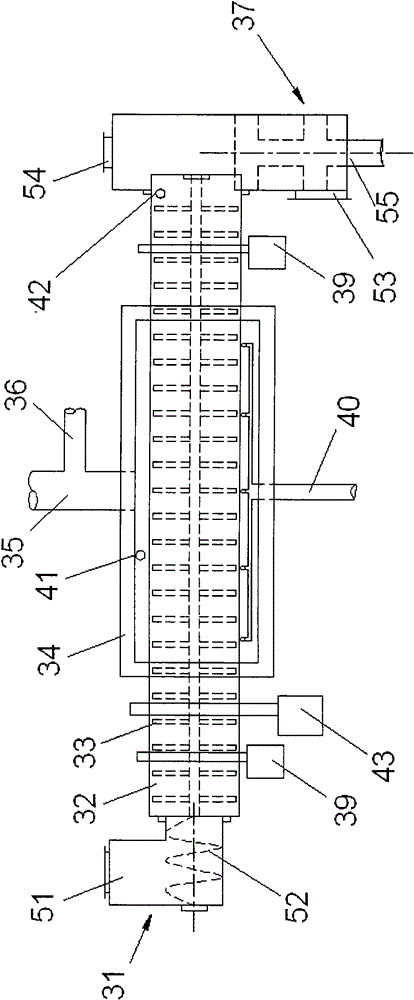

[0014] In order to facilitate the description of the structure configuration of the present invention and the state of use, the following embodiments will refer to the accompanying drawings to carry out an exemplary embodiment of the low-temperature anoxic carbonization system equipment provided by the present invention and the low-temperature anoxic carbonization rotary furnace used therein illustrate.

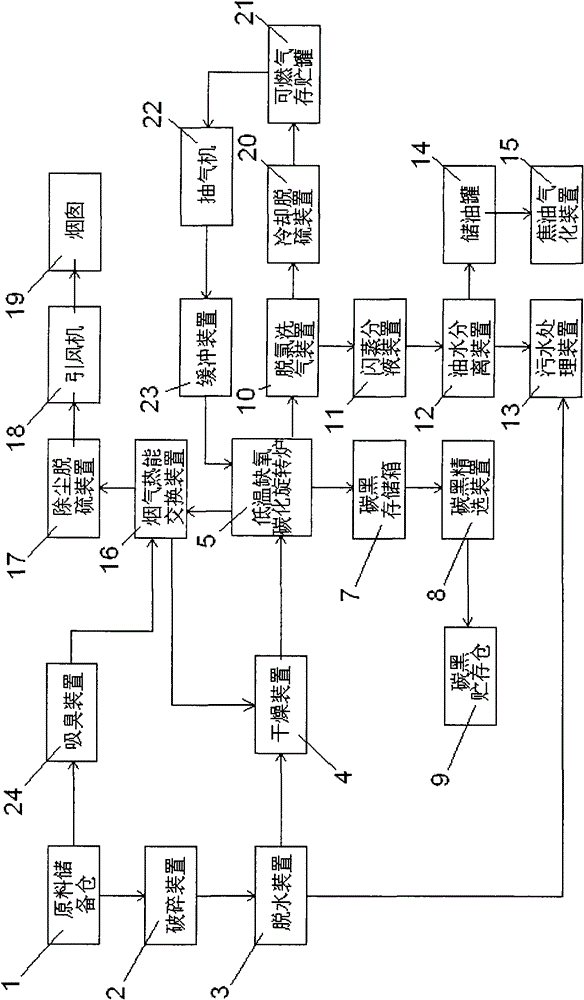

[0015] Such as figure 1 As shown, the present invention provides a low-temperature anoxic carbonization system equipment, including a raw material preparation part, a low-temperature anoxic carbonization part, a product processing part, and a heat exchange part; wherein the raw material preparation part includes a raw material storage bin 1 for storing garbage raw materials. The crushing device 2 for crushing the waste materials from the raw material storage bin, the dehydration device 3 for dehydrating the crushed waste materials, and the drying device 4 for hygroscopic dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com