System and method for deeply purifying coal

A deep purification and coal technology, applied in solid separation, flotation, etc., can solve the problems of unfeasible economical flotation, unsatisfactory flotation results, and difficult improvement of hydrophobicity, so as to improve the comprehensive utilization rate and save the dosage of chemicals , the effect of low ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

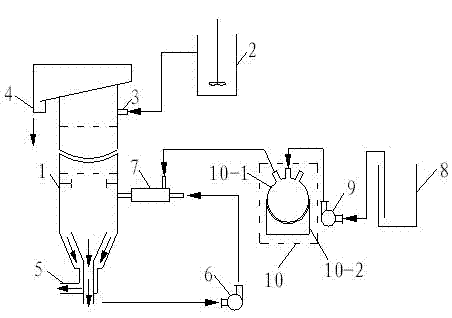

[0020] Embodiment one, as figure 1 As shown, the coal deep purification system is mainly composed of a flotation column 1, a mixing tank 2, a circulation pump 6, a bubble generator 7, an oil storage tank 8, a fuel pump 9, and an oil gas generator 10. The top of the flotation column 1 is provided with a foam The discharge port 4 is provided with a tailings discharge port 5 at the bottom, the mixing tank 2 is connected to the feeding port 3 of the flotation column 1 through the pipeline, the bubble generator 7 is connected to the cylinder of the flotation column 1 through the pipeline, and the bubble generator The inlet of 7 and the outlet of flotation column 1 are respectively connected with circulating pump 6 through pipelines, and bubble generator 7 is connected with an oil-gas generator 10 through pipelines, and oil-gas generator 10 is provided with the spherical container 10-1 of three ports and the device The electric heating jacket 10-2 under the spherical container 10-1 ...

Embodiment 2

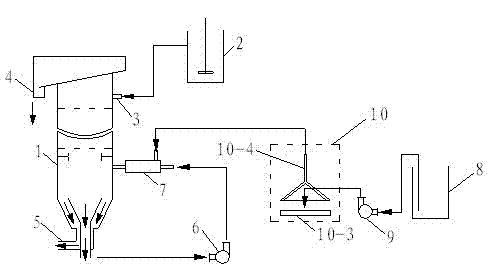

[0022] Embodiment two, such as figure 2 As shown, the coal deep purification system is essentially the same as the first embodiment, and the same parts are omitted. The difference is that the oil and gas generator 10 is composed of an electric heating plate 10-3 and a conical gas collecting hood 10-4 arranged above the electric heating plate 10-3.

[0023] The method for deep coal purification: the oil and gas outlet of the oil and gas generator 10 is connected to the suction port of the bubble generator 7 through the connecting pipeline, and the connection of the inlet and outlet is sealed; the power supply of the electric heating plate 10-3 of the oil and gas generator 10 is turned on , so that the heating temperature of the electric heating plate 10-3 reaches 200-250° C.; turn on the circulating pump 6 of the flotation column 1, so that the 1 / 3-2 / 3 column volume of clear water added in advance in the flotation column 1 will be generated by air bubbles The device 7 circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com