Galactosylated chitosan scaffold material for bioartificial liver and preparation method thereof

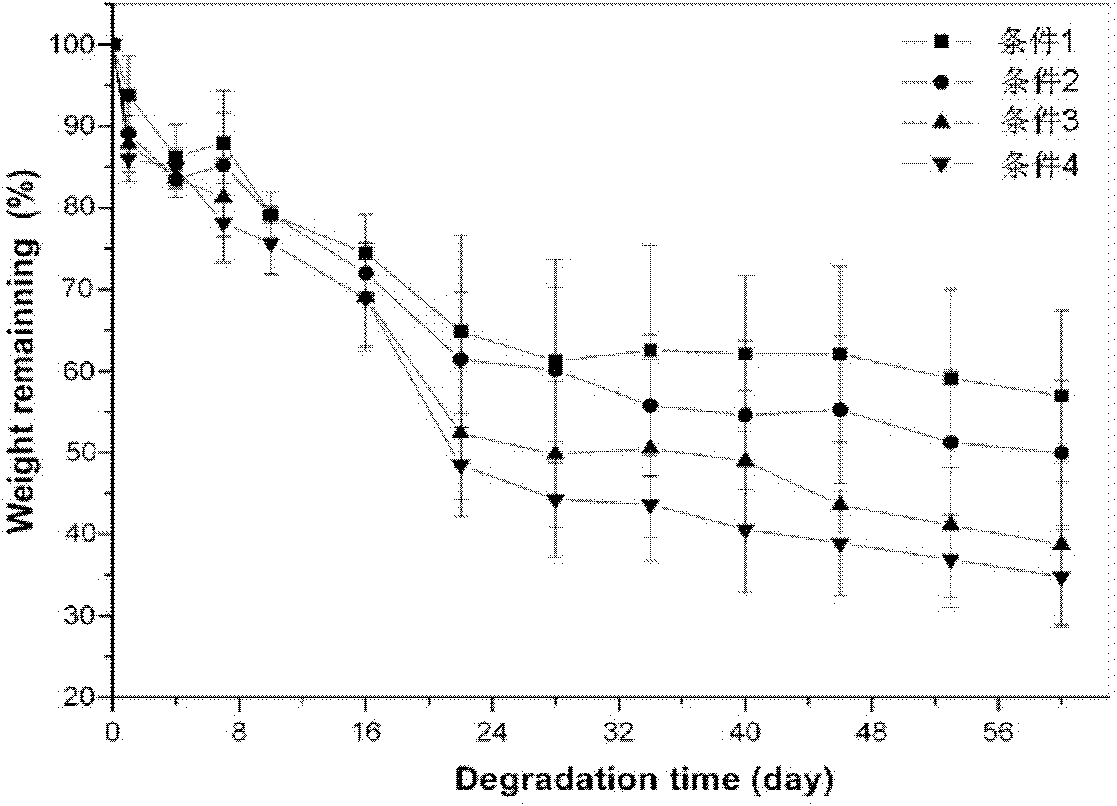

A technology for converting chitosan and a scaffold material, which is applied in the field of bioartificial liver galactosylated chitosan scaffold material and its preparation, and achieves the effects of low cytotoxicity, improved compressive strength and slowed down degradation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

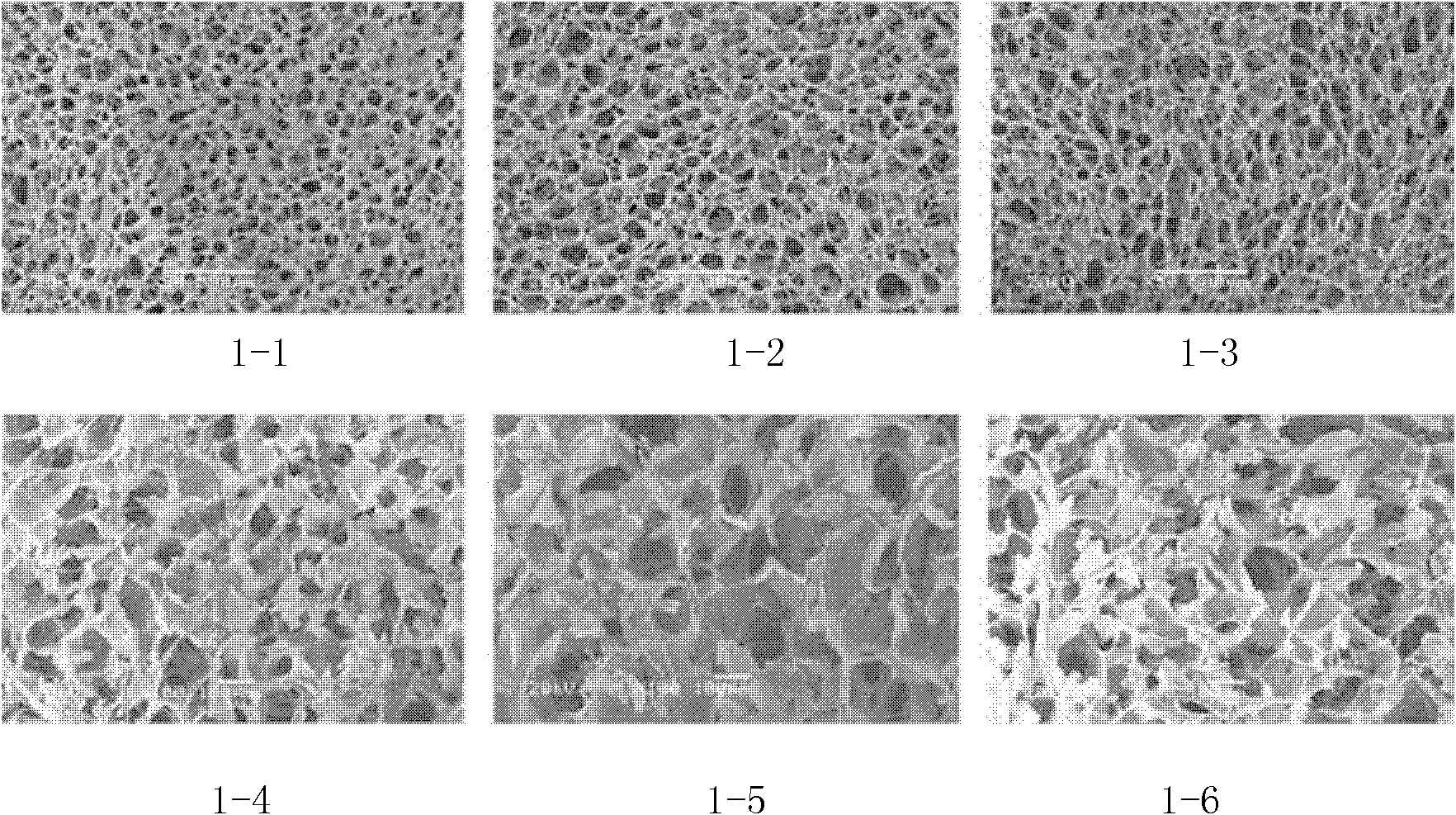

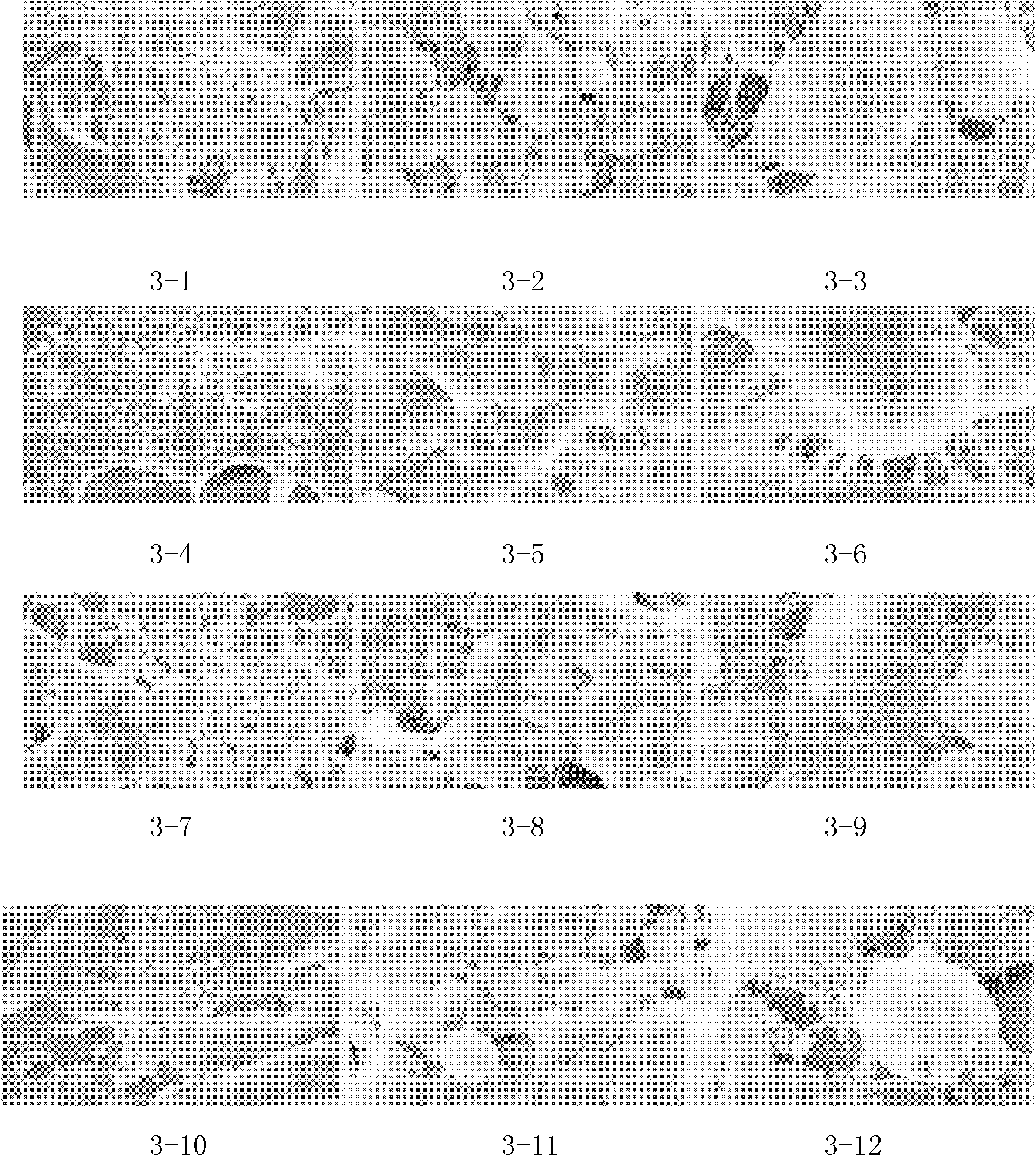

Embodiment 1

[0033] 3.24g chitosan is dissolved in the tetramethylethylenediamine / hydrochloric acid buffer solution of 240ml pH4.5, 7.16g lactobionic acid is dissolved in the tetramethylethylenediamine / hydrochloric acid buffer solution of 80ml pH4.5, two solutions combine Add 2.5ml of 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide hydrochloride / N-hydroxysuccinic acid mixed solution (the molar ratio of both is 1:1) active intermediate, Activation reaction at about 25°C for 72 hours to prepare galactosylated chitosan, after the reaction, use 0.1M / L NaOH solution to adjust to near neutrality (pH about 7.0), repeated filtration and dialysis, and freeze-drying to obtain purified galactose Chitosan;

[0034] Galactosylated chitosan and oxidized sodium alginate were formulated into 2.5% solutions respectively, and the two solutions were mixed according to the dry weight ratio of galactosylated chitosan and oxidized sodium alginate at a ratio of 2:1, and stirred at 25°C for reaction About 10 minu...

Embodiment 2

[0037] 1.62g chitosan is dissolved in the tetramethylethylenediamine / hydrochloric acid buffer solution of 120ml pH4.7, 3.58g lactobionic acid is dissolved in the tetramethylethylenediamine / hydrochloric acid buffer solution of 40ml pH4.7, two solutions combine Add 1.0ml of 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide hydrochloride / N-hydroxysuccinic acid mixed solution (the molar ratio of the two is 1:2) active intermediate, Activation reaction at about 20°C for 96 hours to prepare galactosylated chitosan, after the reaction, use 0.15M / L ammonia solution to adjust to near neutrality (pH about 7.2), repeat filtration and dialysis, and freeze-dry to obtain purified galactose Chitosan;

[0038] Prepare 2.5% solutions of galactosylated chitosan and oxidized sodium alginate respectively, mix the two solutions according to the dry weight ratio of galactosylated chitosan and oxidized sodium alginate at a ratio of 3:1, and stir at about 20°C React for about 20 minutes, pour into the ...

Embodiment 3

[0041] 1.62g chitosan is dissolved in the tetramethylethylenediamine / hydrochloric acid buffer solution of 120ml pH4.8, 3.58g lactobionic acid is dissolved in the tetramethylethylenediamine / hydrochloric acid buffer solution of 40ml pH4.8, two solutions combine Add 1.2ml of 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide hydrochloride / N-hydroxysuccinic acid mixed solution (the molar ratio of both is 2:1) active intermediate, The galactosylated chitosan was prepared by activating the reaction at about 30°C for about 60 hours. After the reaction, it was adjusted to near neutrality (pH about 7.1) with 0.15M / L KOH solution, filtered and dialyzed repeatedly, and lyophilized to obtain purified semi-galactosyl chitosan. Lactosylated chitosan;

[0042] Prepare 2.5% solutions of galactosylated chitosan and oxidized sodium alginate respectively, mix the two solutions according to the dry weight ratio of galactosylated chitosan and oxidized sodium alginate at a ratio of 4:1, and stir at abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com